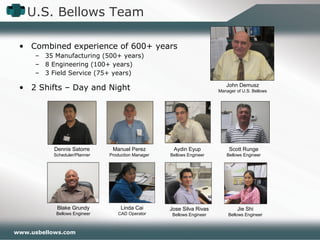

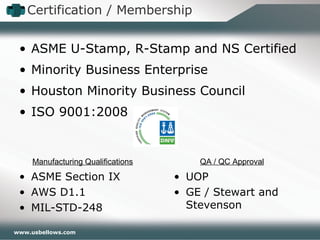

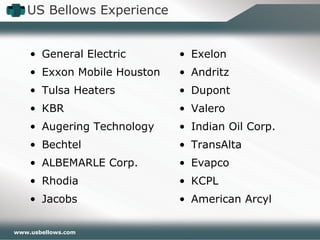

This document provides information about U.S. Bellows, Inc., a manufacturer of metallic and fabric expansion joints. It discusses U.S. Bellows' certifications, manufacturing facility, team members, history since the 1960s, and membership in industry organizations. It also promotes U.S. Bellows' capabilities including fast turnaround, repair, replacement, refurbishing, and quick delivery of expansion joints.