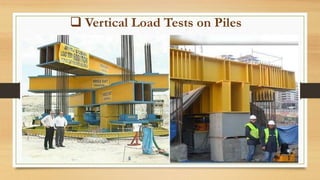

Initial and routine load tests are conducted on piles to confirm design load calculations. Initial tests apply 2.5 times the safe carrying capacity to piles and routine tests apply 1.5 times. Initial tests establish acceptance limits for routine tests. Routine tests are conducted on 1/2-2% of piles to ensure safe load capacity and detect unusual performance. Vertical, lateral, and pull-out load tests are conducted according to IS standards and involve measuring pile settlement under increasing loads held for durations. Acceptance criteria consider settlement and load levels.