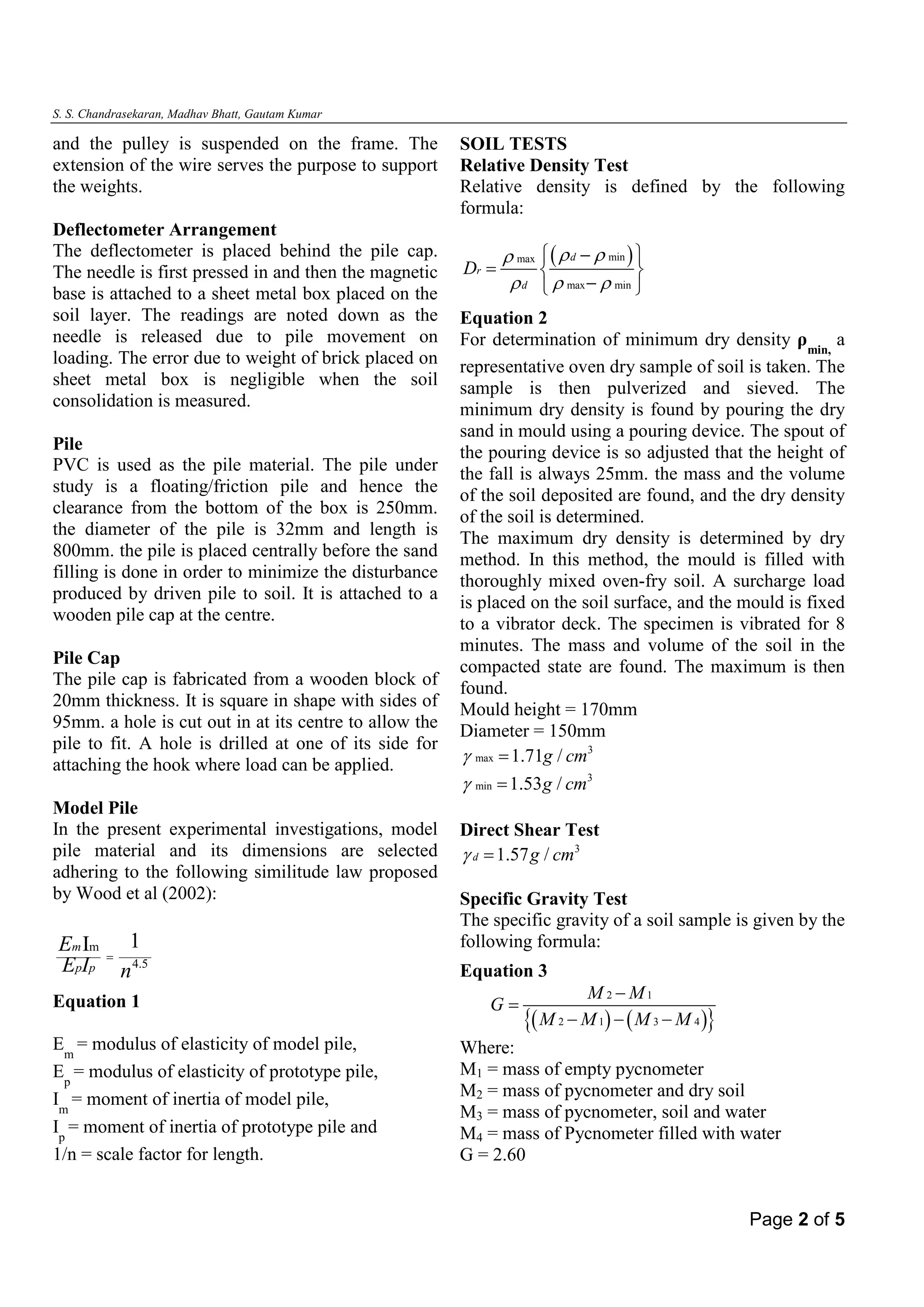

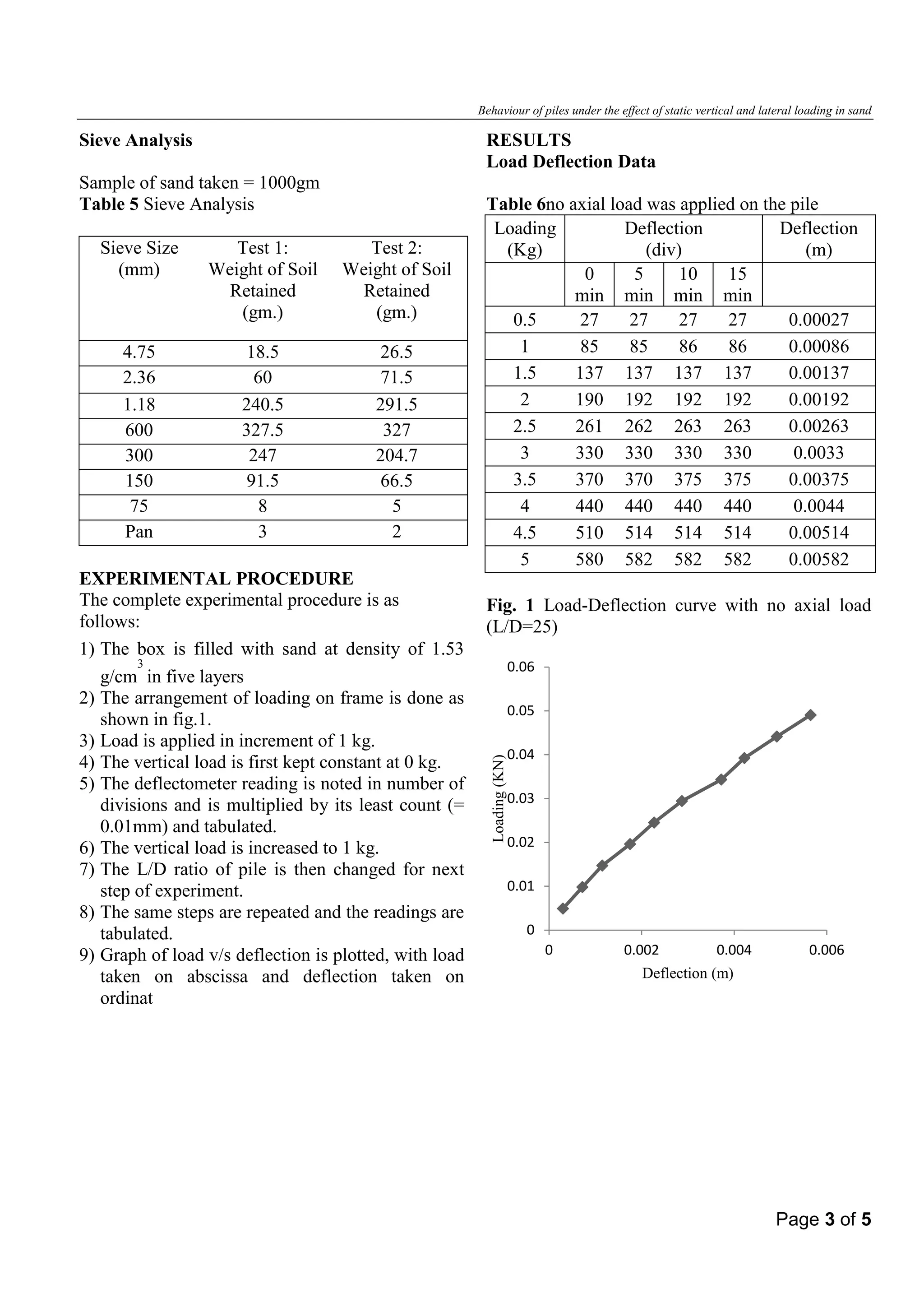

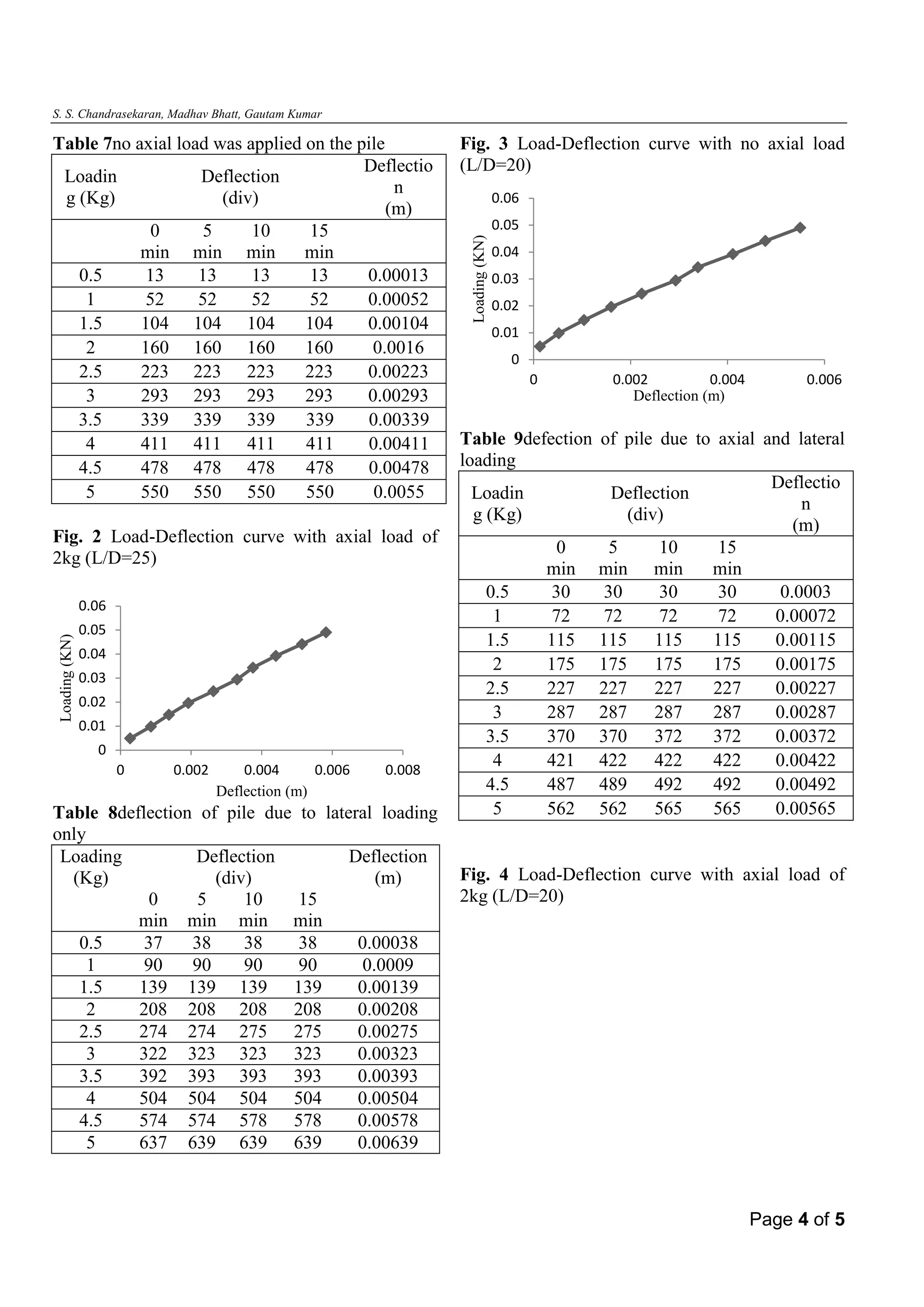

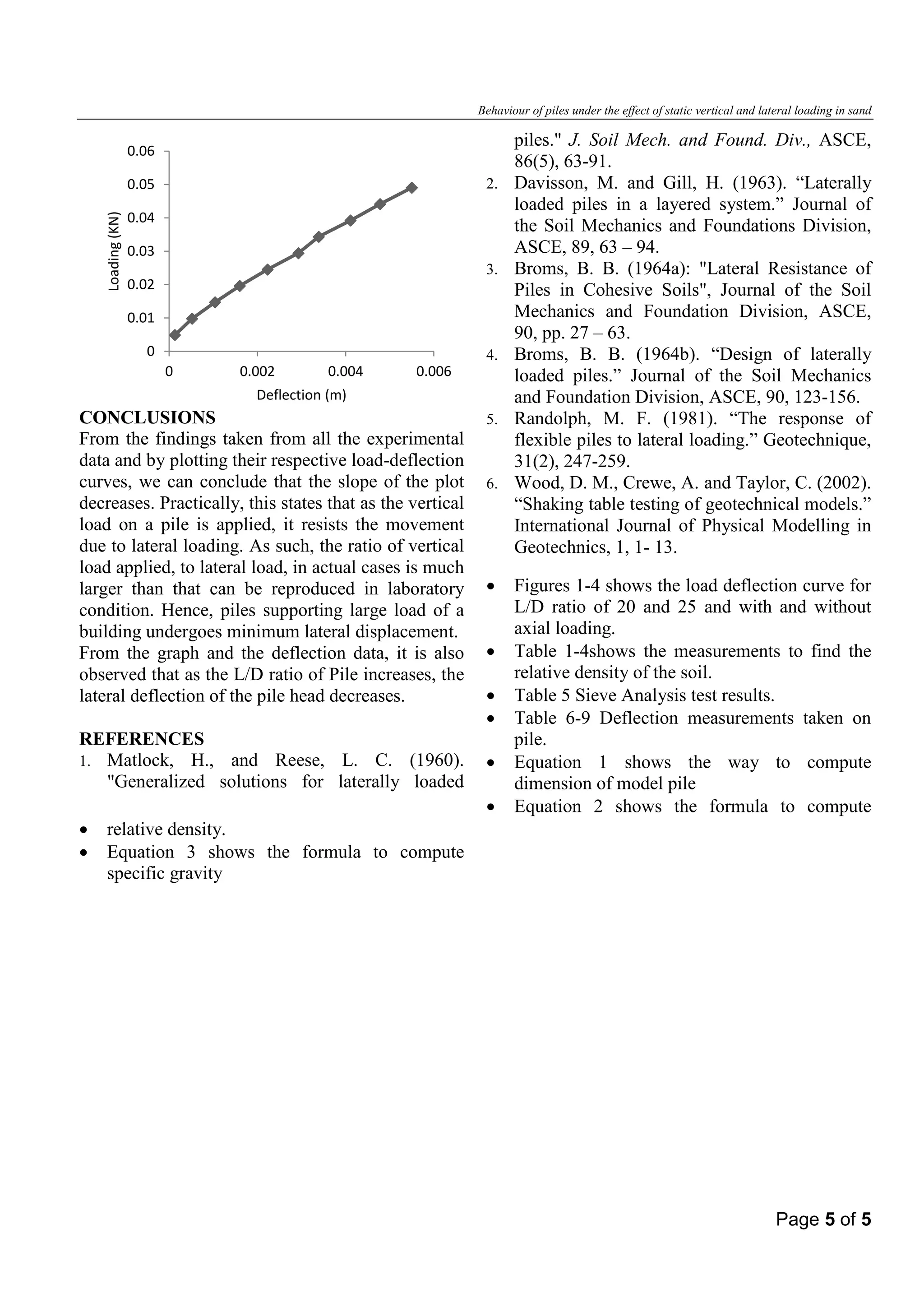

The document summarizes an experimental study on the behavior of piles under static vertical and lateral loading in sand. Pile load tests were conducted with model PVC piles installed in a sand-filled box. Piles were loaded with different vertical and lateral loads and deflections were measured. Results show that lateral deflection decreases with increasing pile length-to-diameter ratio and when a vertical load is applied. Load-deflection curves are presented and conclusions are that vertical loading reduces lateral deflection of the pile and increased L/D ratio also decreases lateral deflection. The study provides data on pile behavior under combined loading conditions in sand.

![Proceedings of Indian Geotechnical Conference

December 22-24,2013, Roorkee

BEHAVIOUR OF PILES UNDER THE EFFECT OF STATIC VERTICAL AND LATERAL LOADING IN SAND

S. S. Chandrasekaran, Associate Professor, SMBS, VIT University. chandrasekaran.ss@vit.ac.in

M. Bhatt, Student, School of Mechanical and Building Sciences, VIT University. madhav.bhatt31@gmail.com

G. Kumar,Student, School of Mechanical and Building Sciences, VIT University. gaumji22@gmail.com

ABSTRACT: This project reports on the behaviour of single pile due to both vertical and horizontal load applied directly. The cohesionless soil (sandy) was taken and tests were performed on it to find out the property of soil. The sand was filled in the box in five layers (each layer of depth 170mm), each layer compacted using hammer. The pile is then fixed as per the required L/D ratio. The vertical and horizontal load tests were performed and deflection was found using mechanical dial gauges. The curve was drawn and behaviour of pile was found under different vertical and horizontal load.

INTRODUCTION

Pile foundations are the part of a structure used to carry and transfer the load of the structure to the bearing ground located at some depth below ground surface. The main components of the foundation are the pile cap and the piles. Piles are long and slender members which transfer the load to deeper soil or rock of high bearing capacity avoiding shallow soil of low bearing capacity. The main types of materials used for piles are wood, steel and concrete. Piles made from these materials are driven, drilled or jacked into the ground and connected to pile caps.

Piles are frequently subjected to lateral forces and moments viz., i) quay and harbor structures in which horizontal forces are generated due to the impact of ships during berthing and wave action, ii) offshore structures subjected to wind and wave action, iii) tall structures like chimneys, transmission towers subjected to wind loads and iv) in structures situated in earthquake prone areas. In the design of such pile foundations, not only the ultimate loads shall be worked out to arrive at the safe loads but also the deflections need to be worked out. Matlock and Reese (1960)[1] presented a generalized iterative solution method for rigid and flexible laterally loaded piles embedded in soils with two forms of varying modulus with depth. Davisson and Gill (1963)[2] investigated the case of a laterally loaded pile embedded in a layered soil system with a constant (but different) modulus of subgrade reaction in each layer. Broms (1964a, b)[3,4] method is also based on earth pressure theory with simplifying assumption for distribution of ultimate soil resistance along the pile length and this method is applicable for both short piles and long piles. Randolph (1981)[5] studied the problem of flexible piles under lateral loading and proposed algebraic expressions for pile head displacement and rotation.

METHODOLOGY

Wooden Box arrangement

Setup consists of a box made from ply of 6mm thickness having dimension 640mm X 750mm X 850mm. This box is filled with sand in 5 layers. Each layer with a thickness of 170mm. After one layer is filled, it is compacted with to get the required height which was calculated taking in consideration the required density of the sand.

Pulley Arrangement

A wooden frame was fabricated to support the pulley system. Height of the frame is 1000mm, and the bottom support is given by three legs on each side of the frame. A hook is attached to the pile cap at its centre and also at the centre of the frame top flange. A wire is made to pass through this hooks Page 1 of 5](https://image.slidesharecdn.com/1th-07-141106070232-conversion-gate01/75/1-th-07-1-2048.jpg)