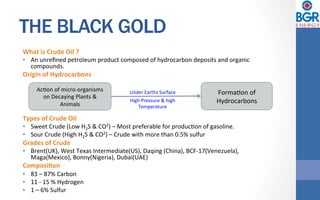

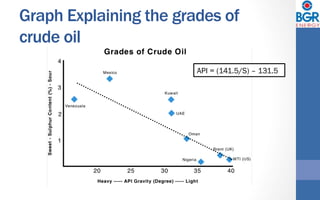

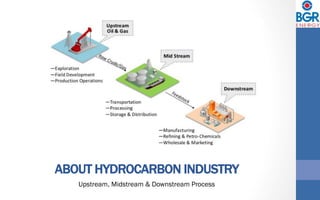

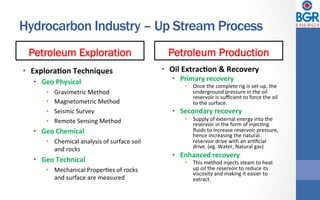

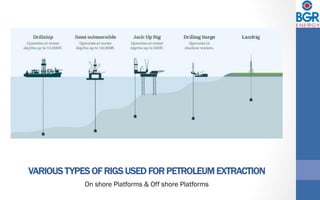

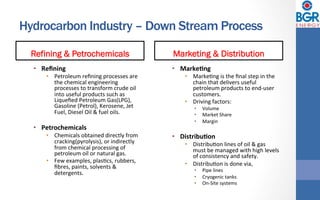

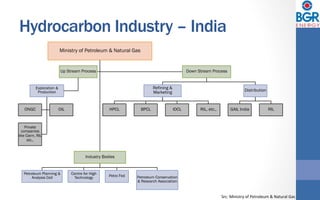

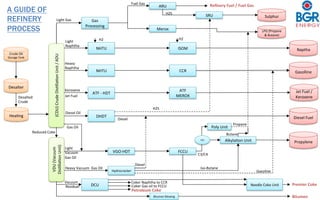

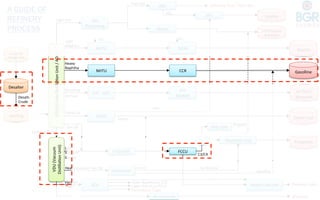

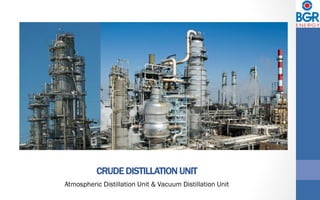

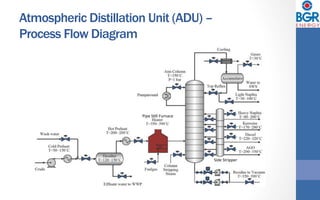

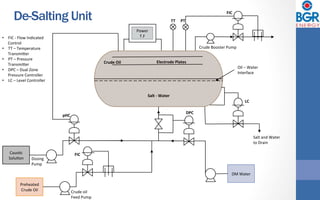

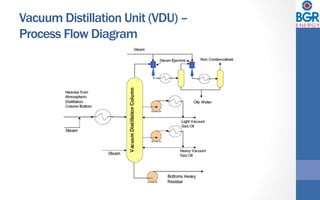

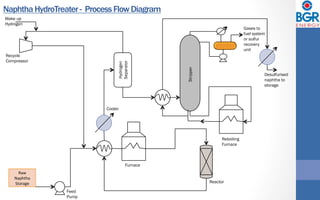

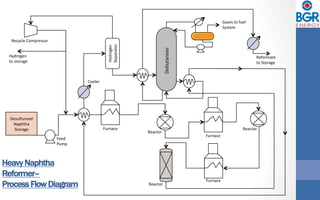

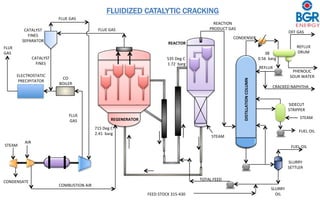

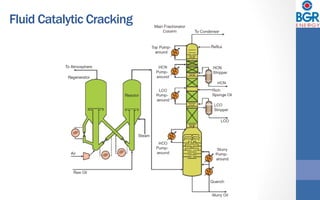

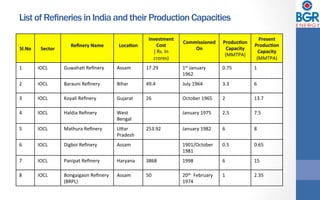

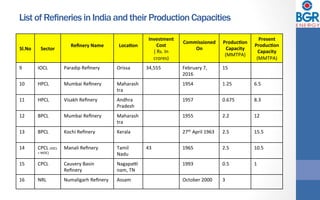

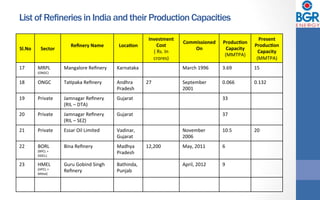

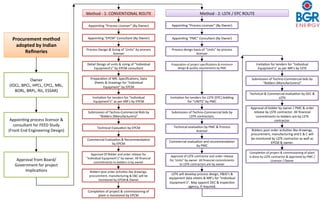

This document provides an overview of the petroleum and petrochemical industry in India. It begins with definitions of crude oil and different types. It then discusses the upstream, midstream, and downstream processes in the hydrocarbon industry including exploration, production, refining, petrochemicals, marketing and distribution. Several key refinery processes are described at a high level like crude distillation, catalytic cracking, and production of gasoline from naphtha. Tables list major Indian refineries and their production capacities. Overall the document serves as an introduction to the petroleum industry supply chain and some important refining technologies.