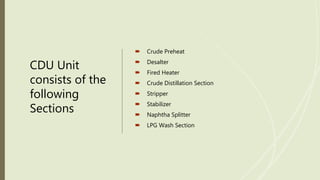

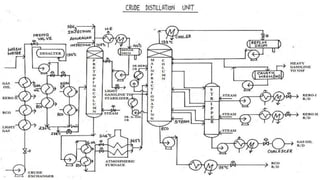

The document presents a detailed overview of a crude distillation unit (CDU), including the various crude oil sources such as Assam and Ravva crudes. It describes the essential components of the CDU, like preheat, desalting, and separation sections, along with operational parameters and product outputs. The stabilizer's role in separating naphtha and liquefied petroleum gas (LPG) is also highlighted, alongside the functioning of the naphtha splitter.