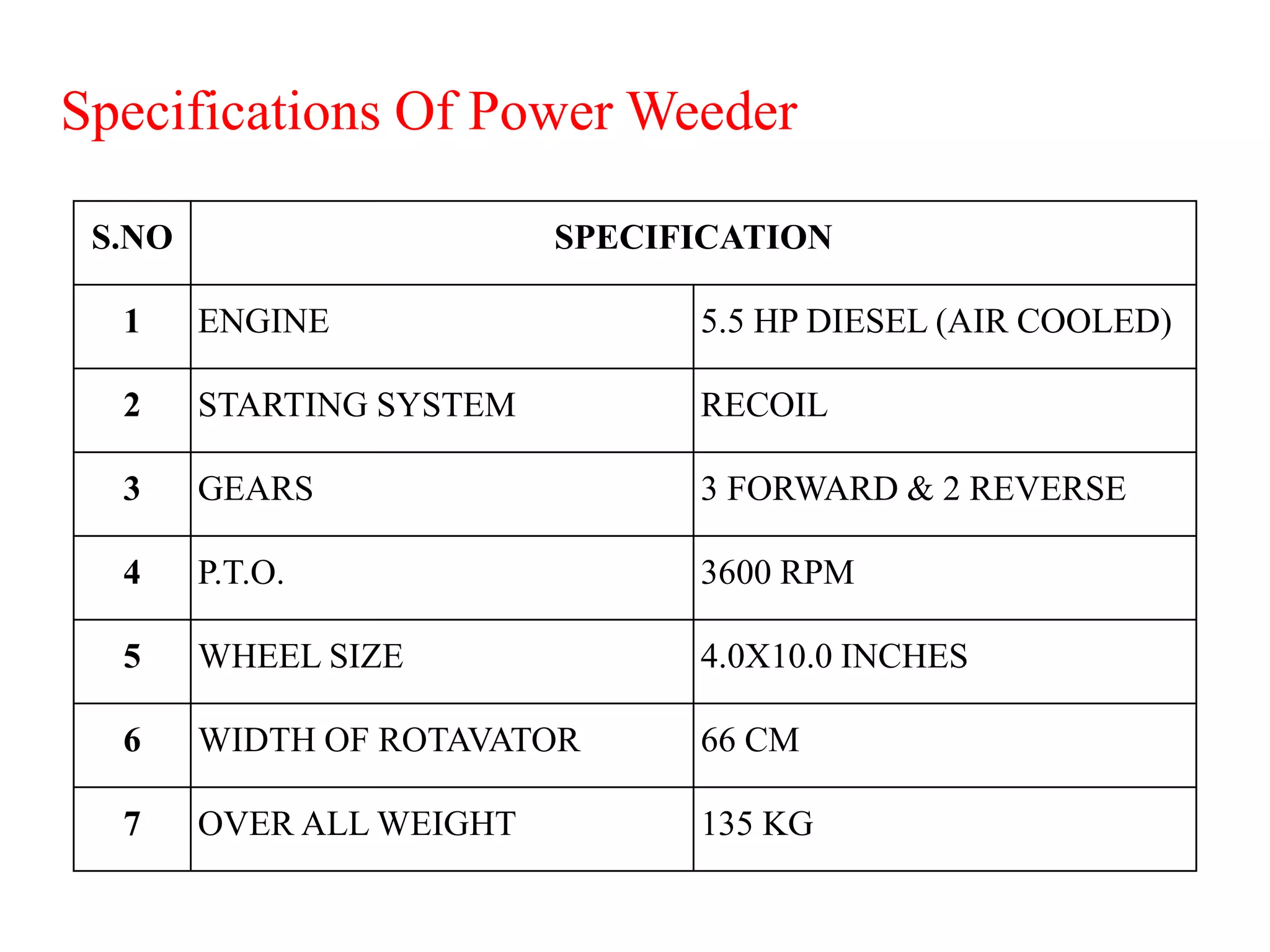

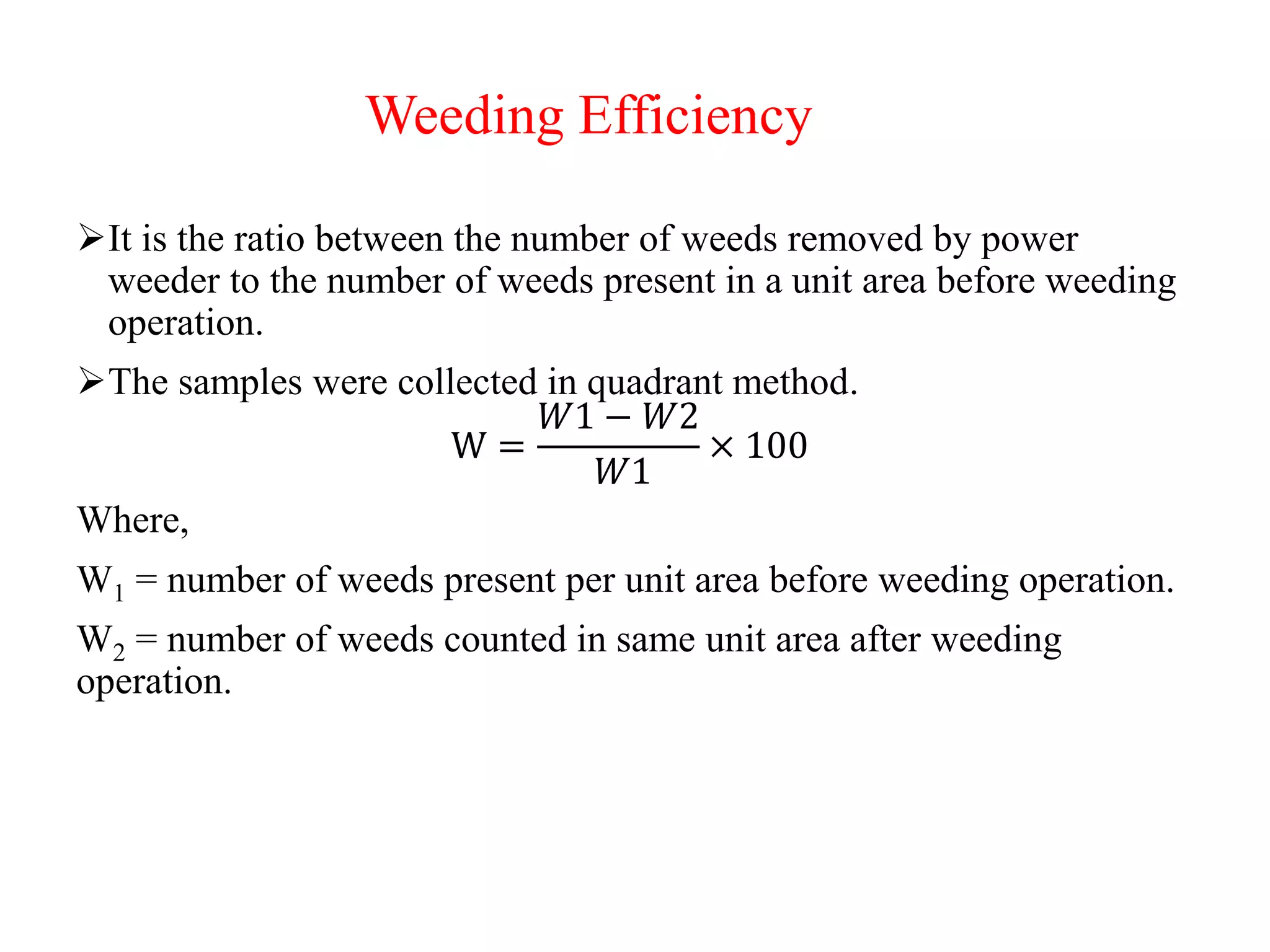

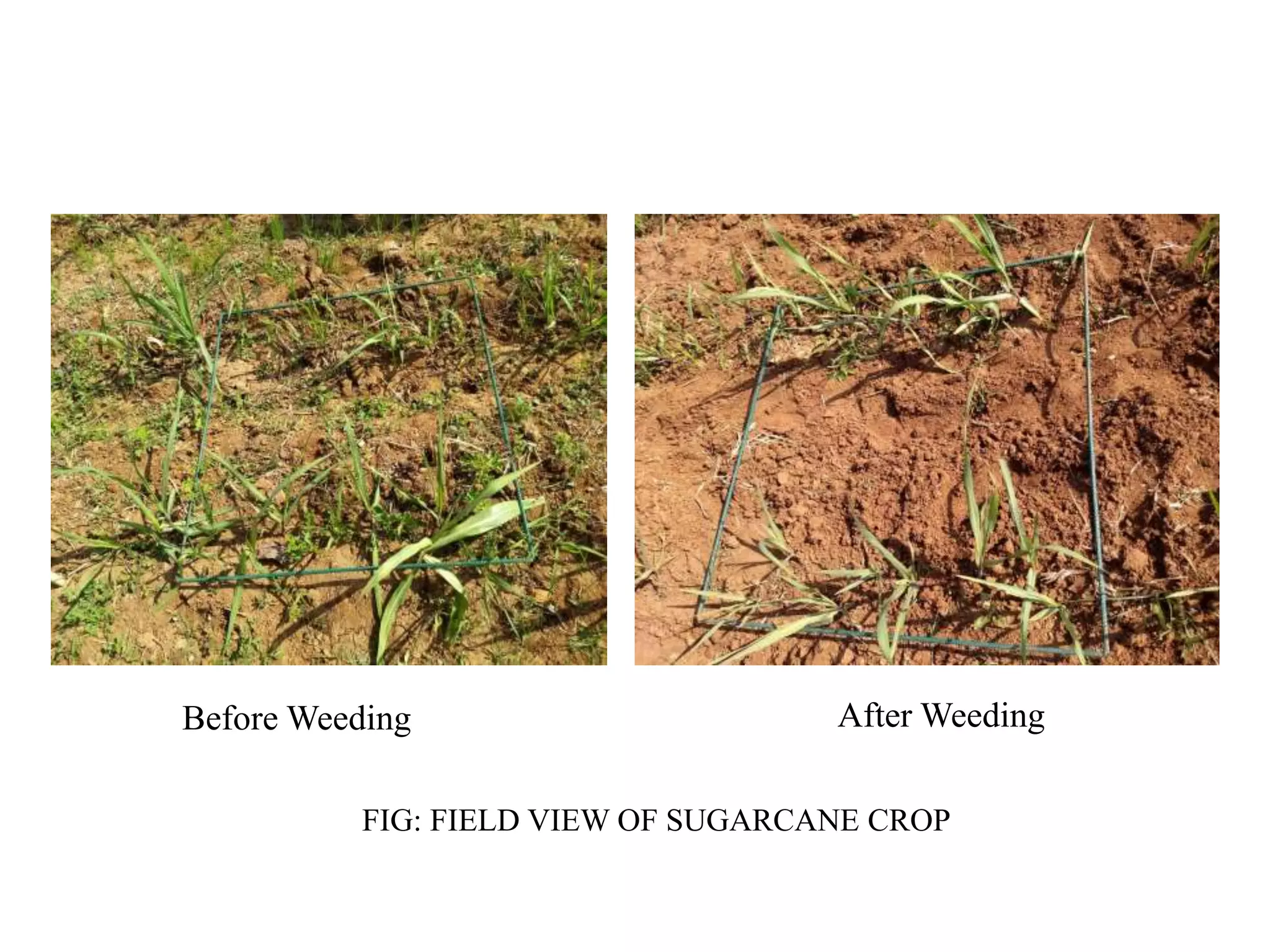

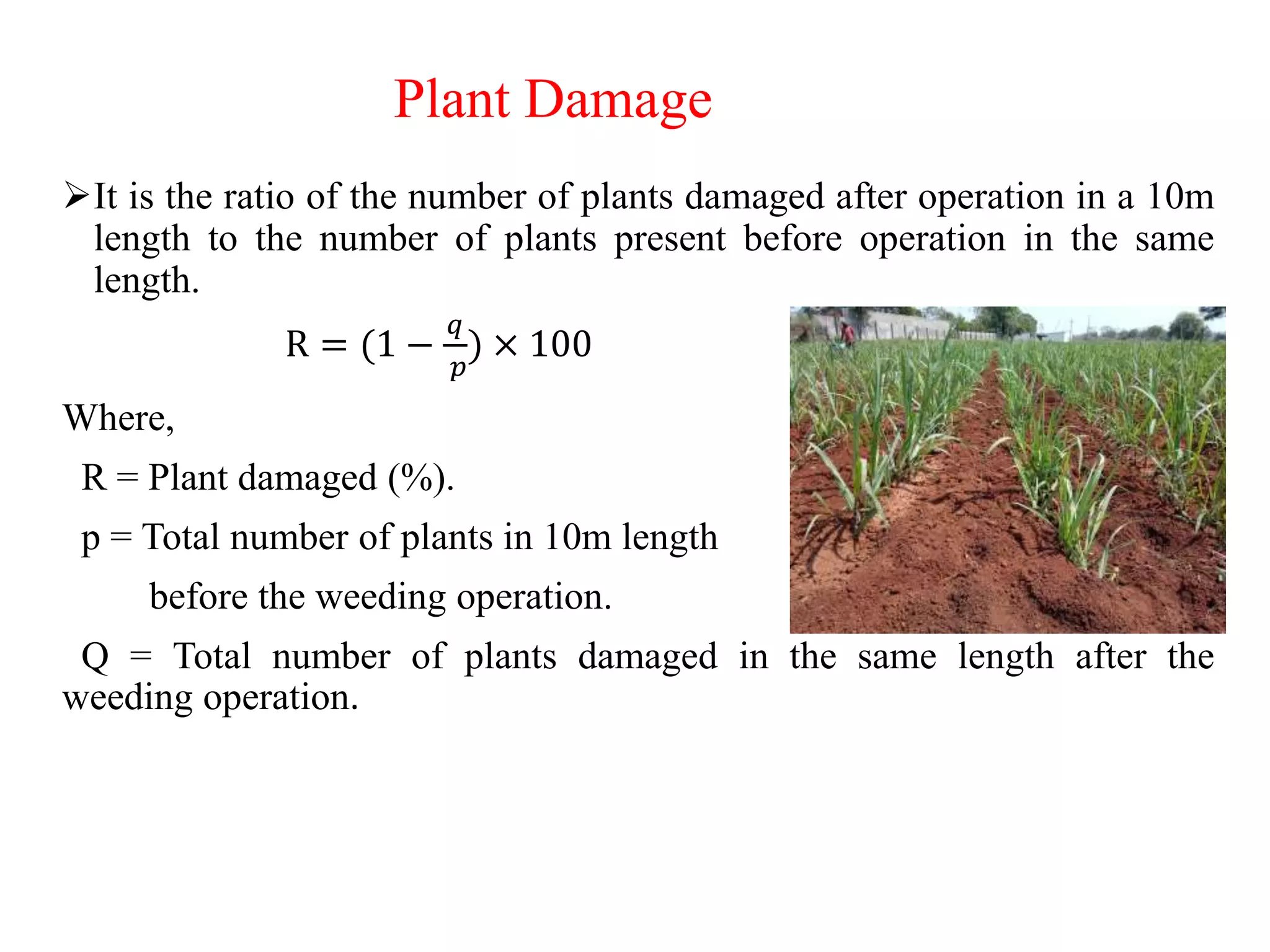

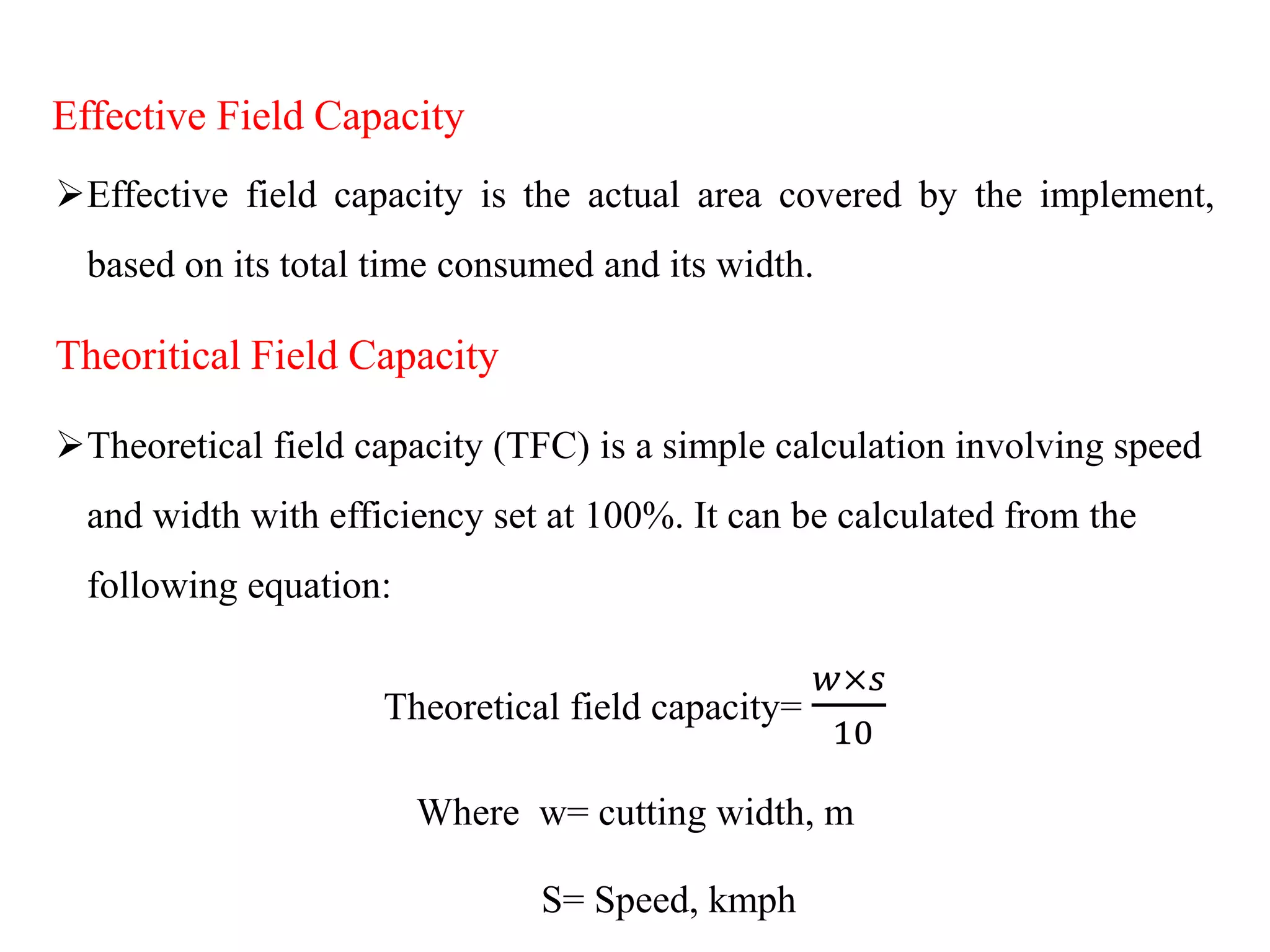

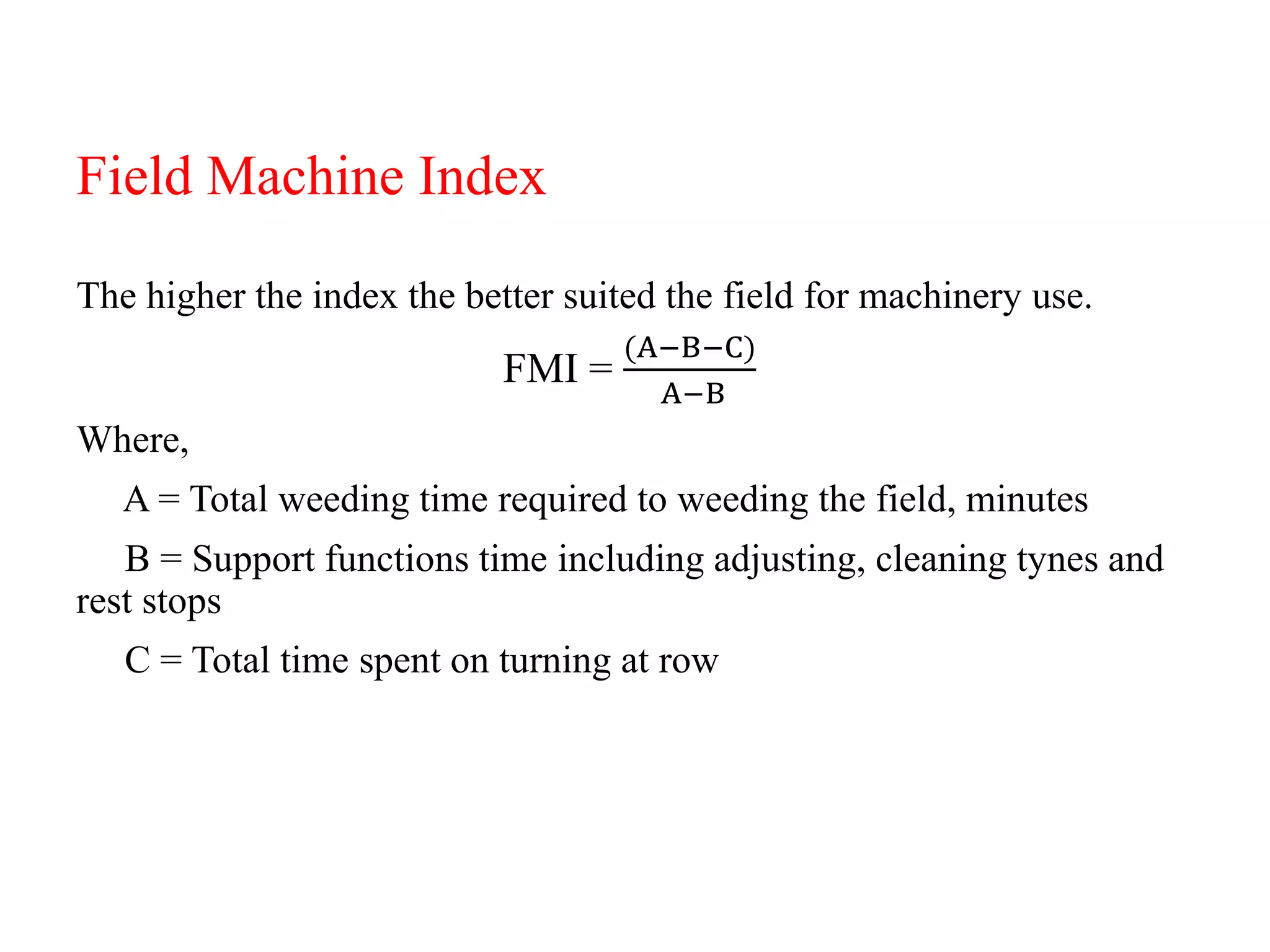

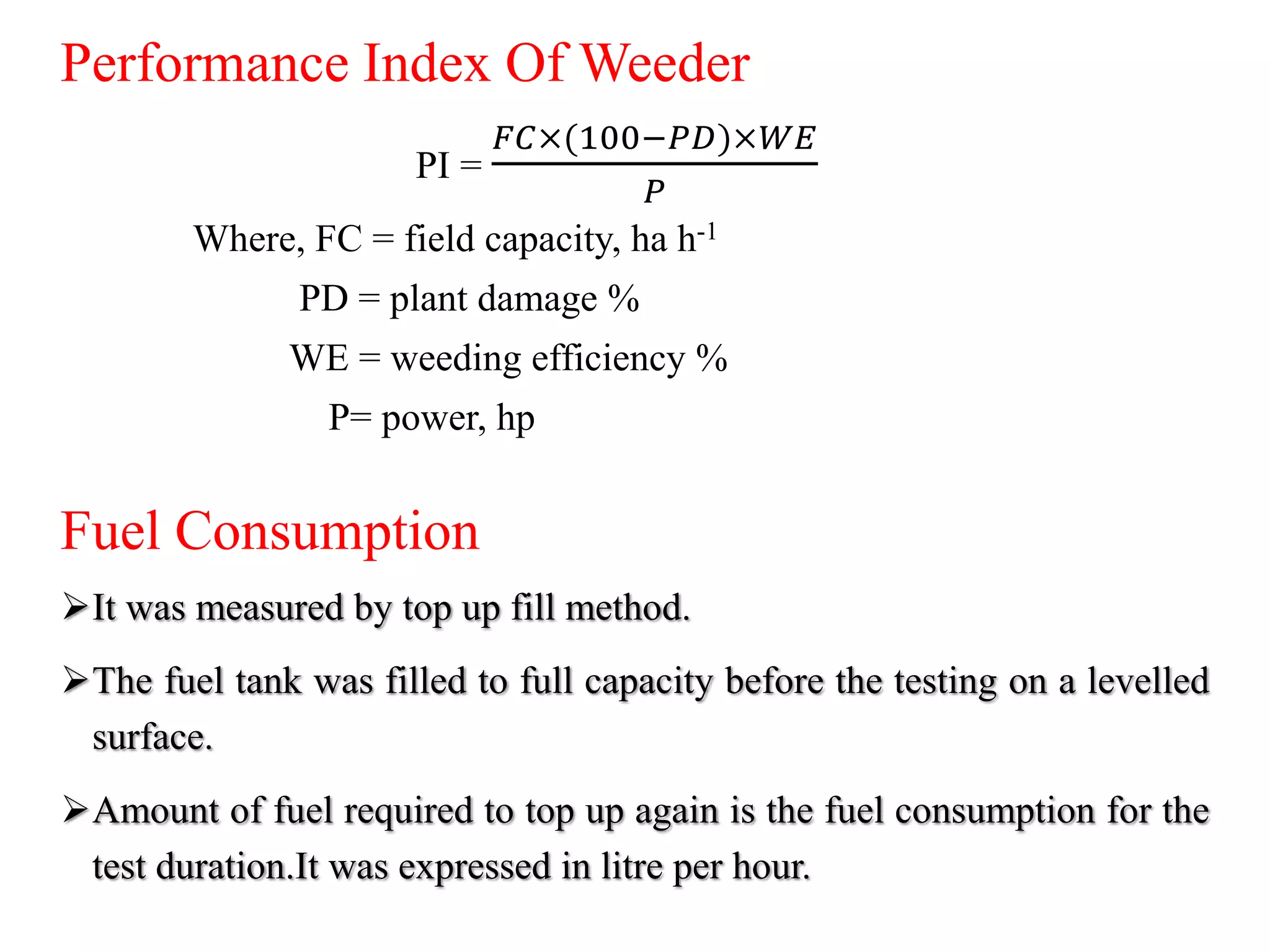

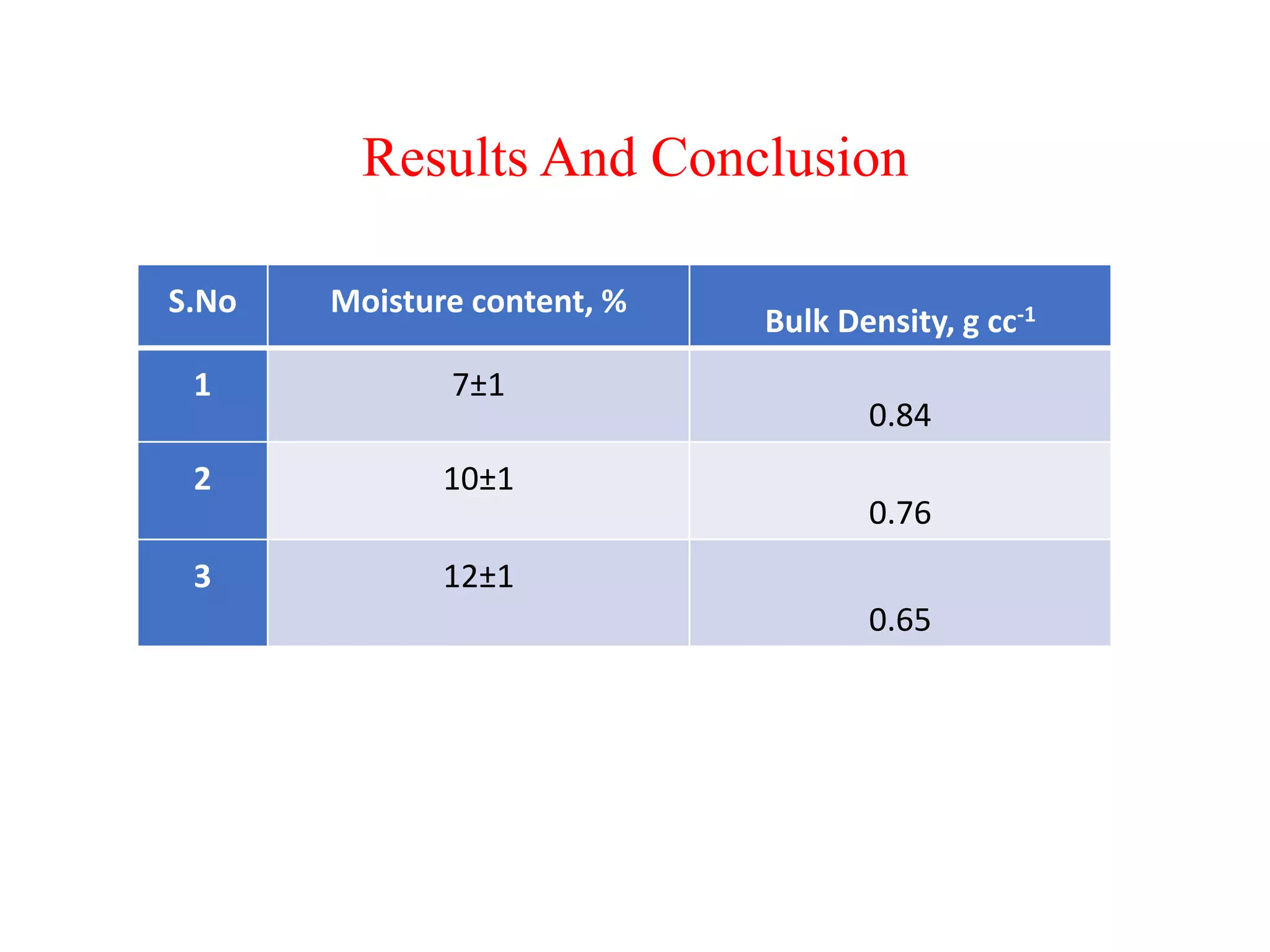

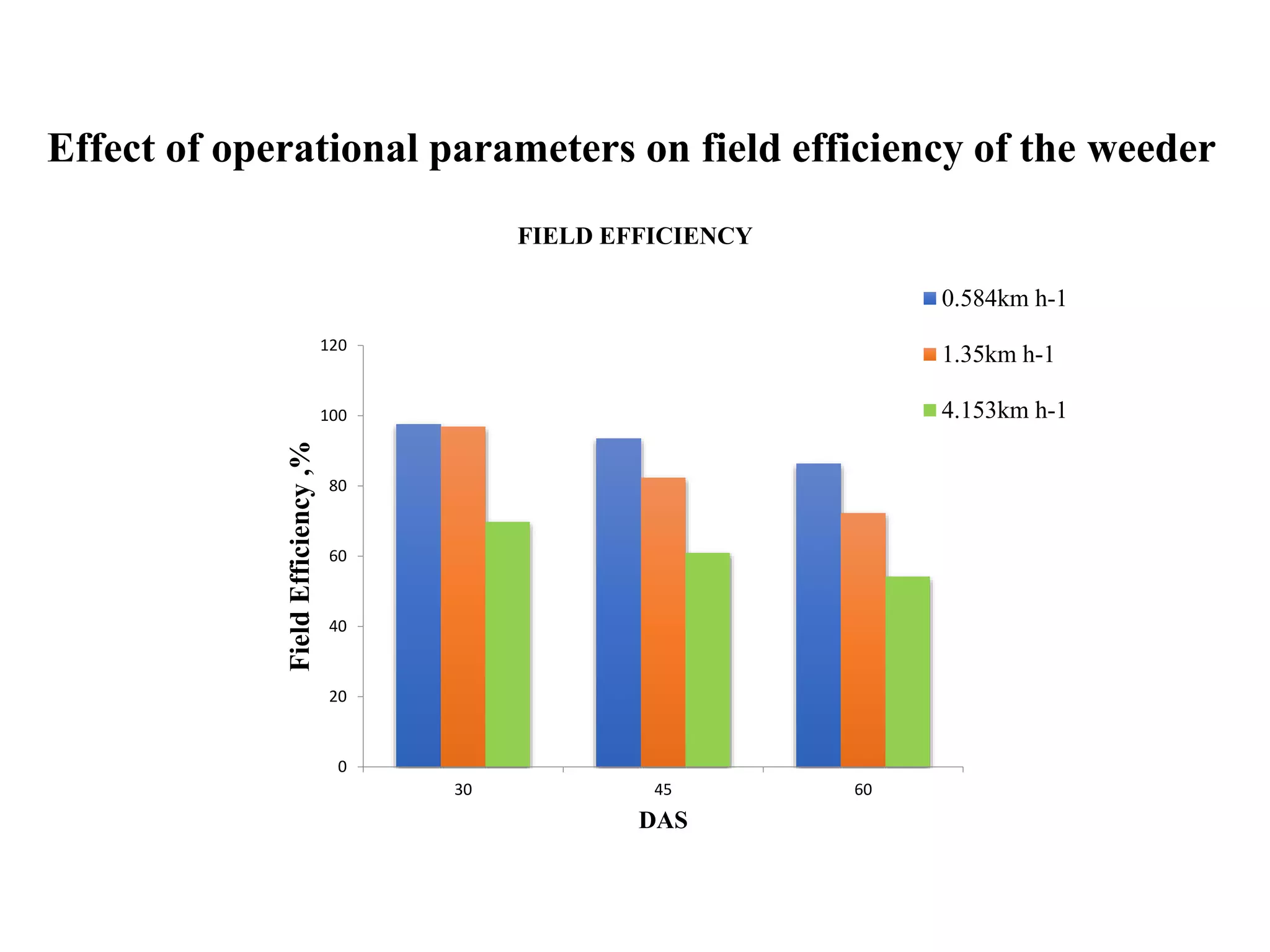

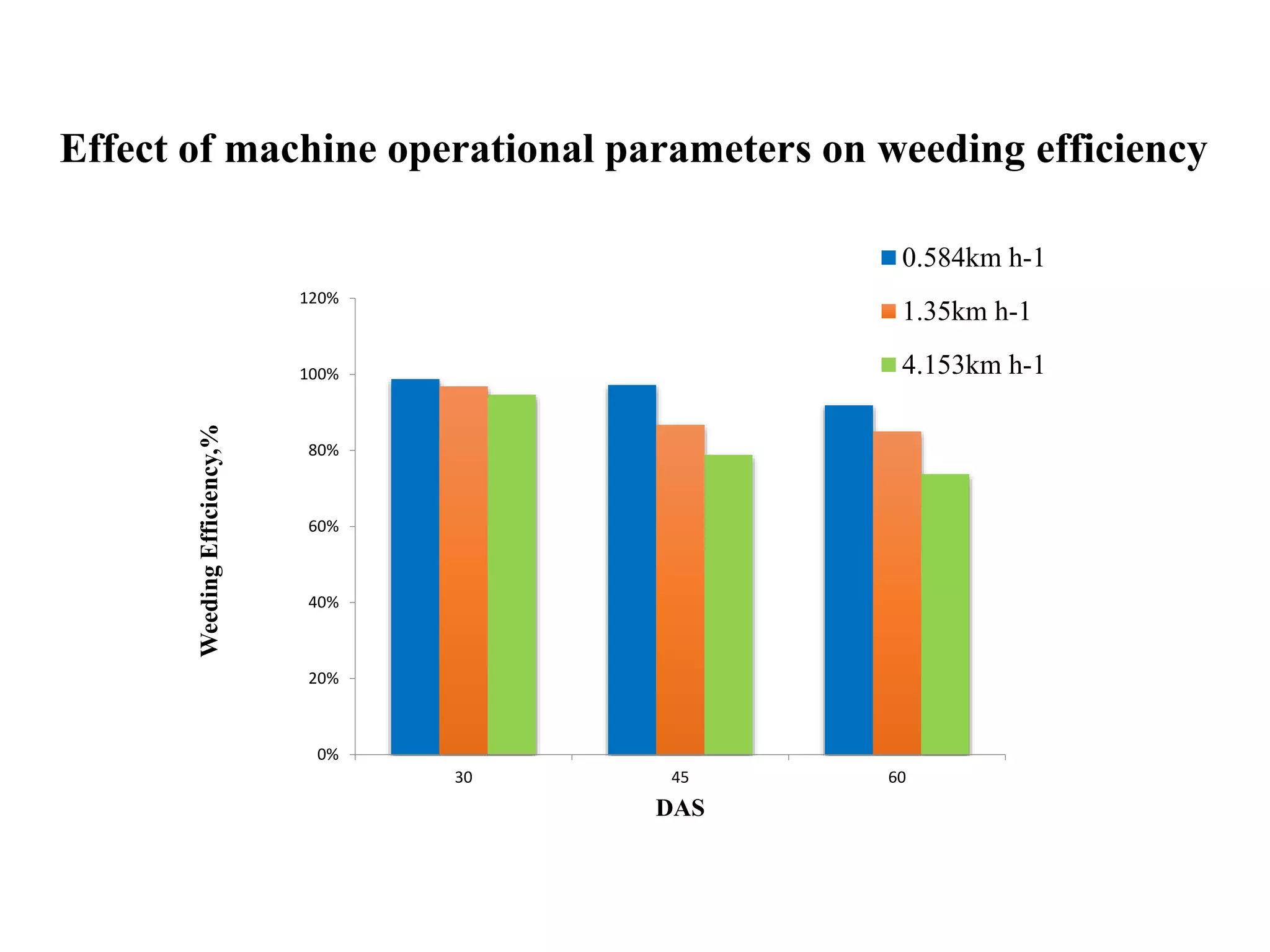

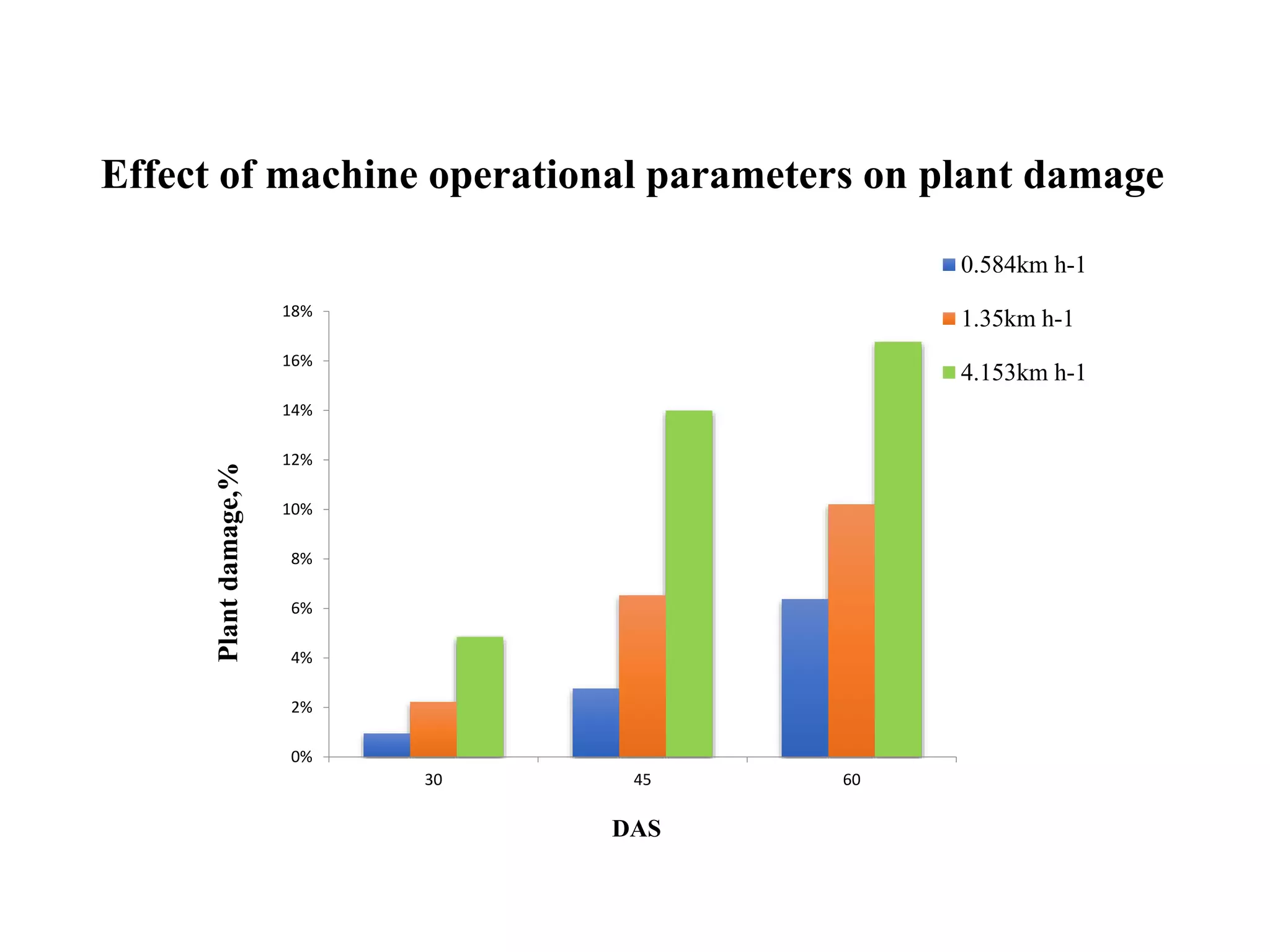

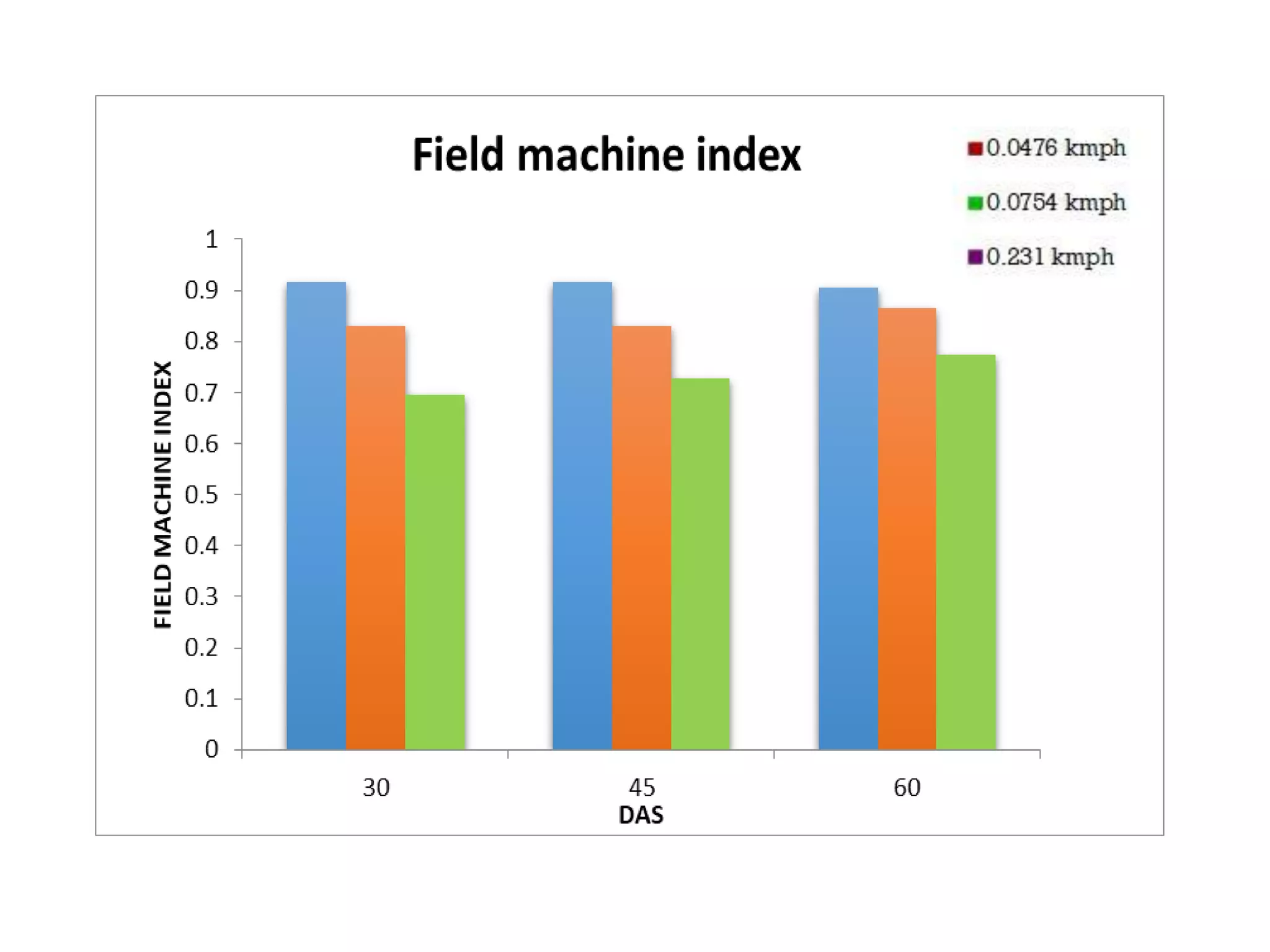

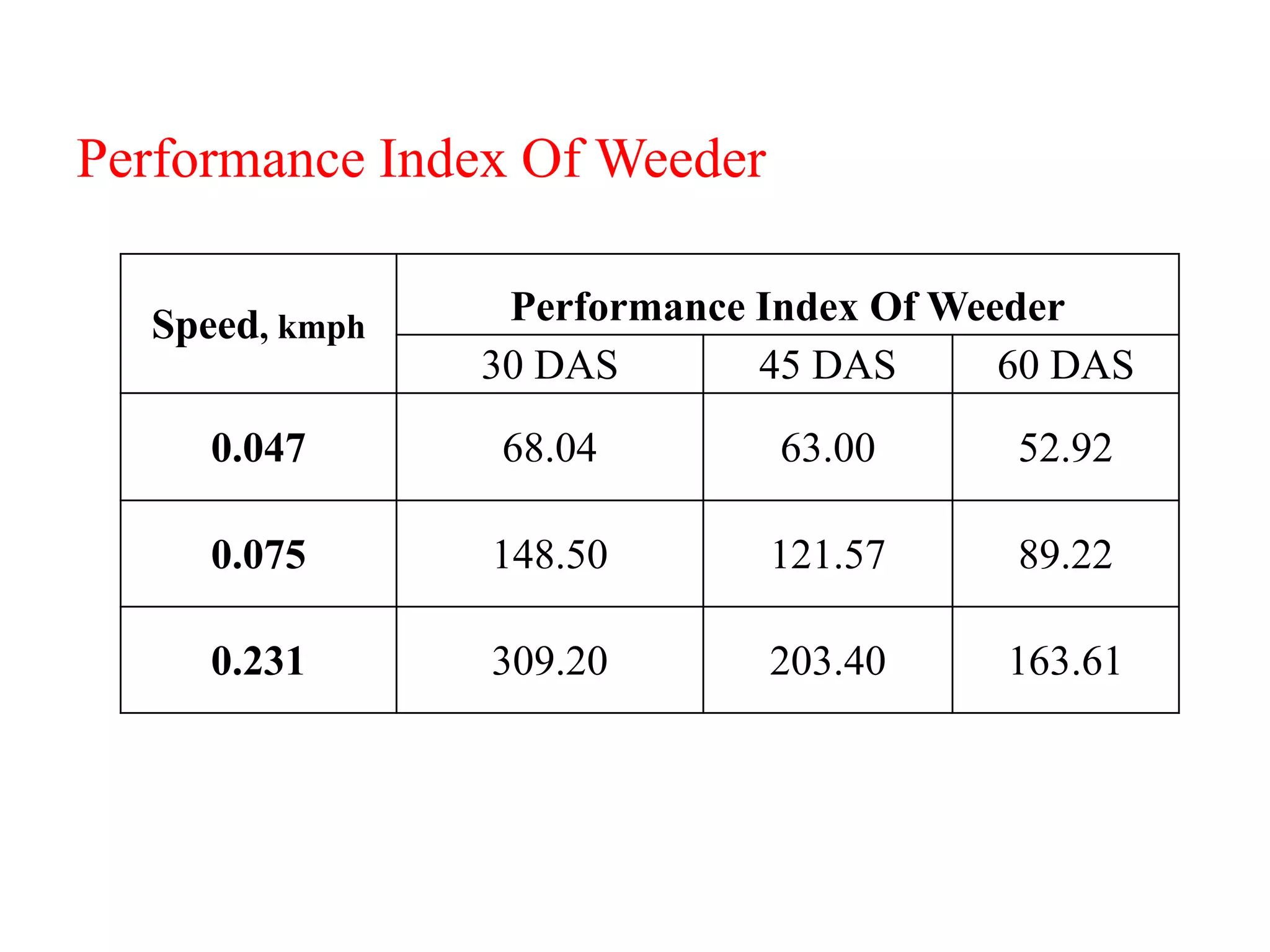

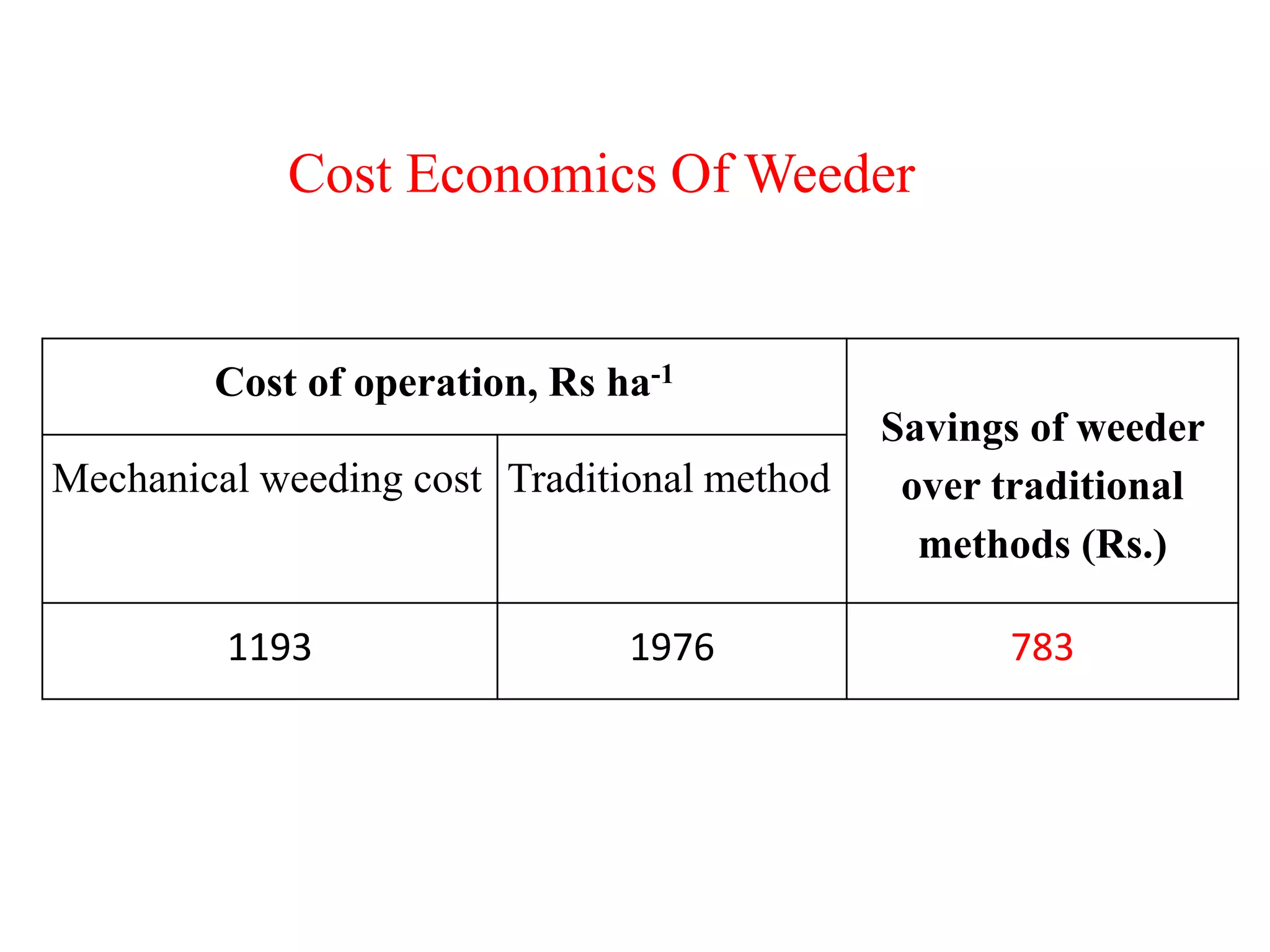

The document evaluates the performance of a power weeder in sugarcane cultivation, highlighting that weeds can significantly reduce yield by competing for resources. It includes specifications of the power weeder, measures of machine performance, and cost economics, comparing it to traditional manual weeding methods. Results indicate that the power weeder is more efficient, with lower cost of operation and better weed control efficiency.