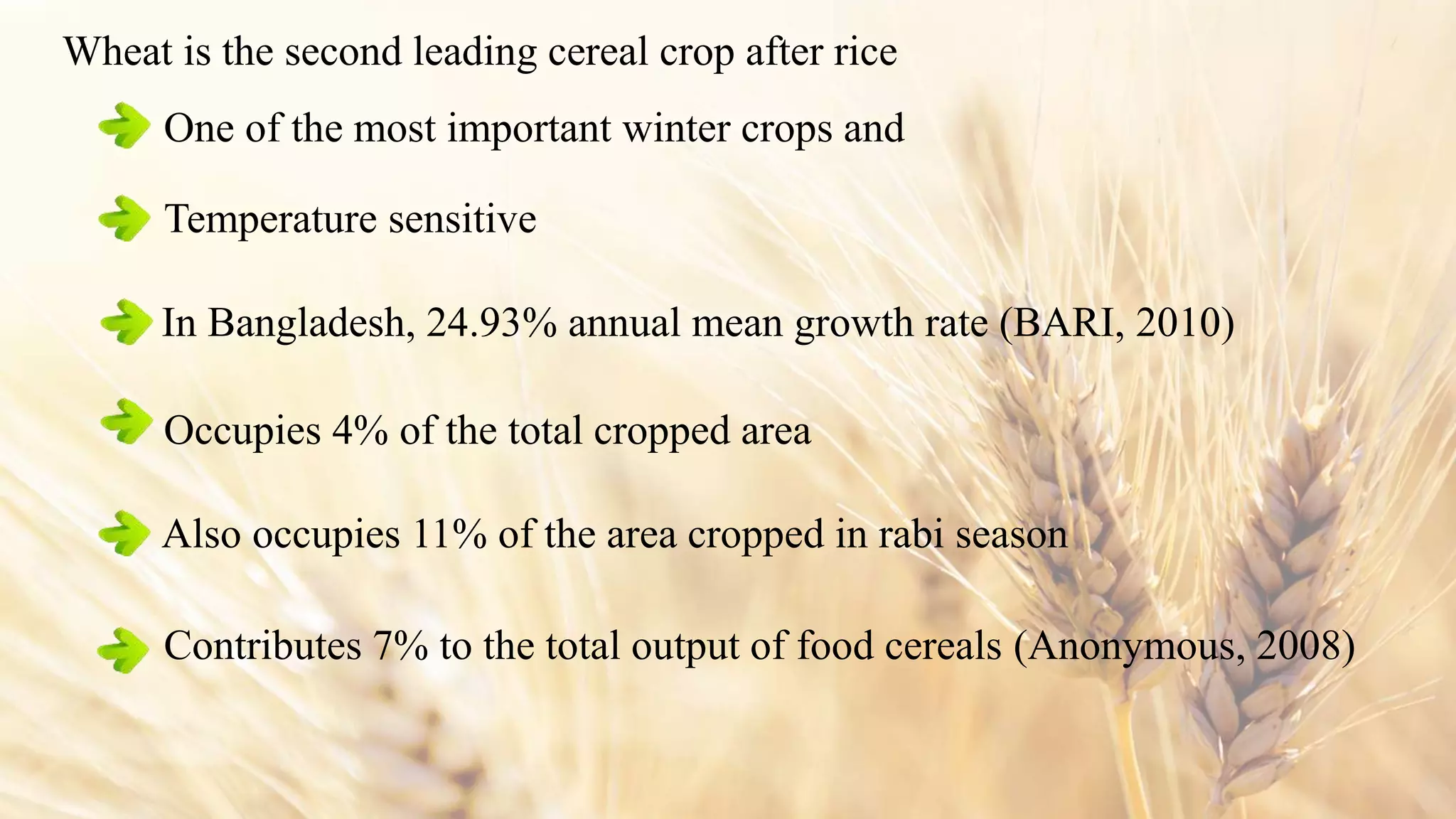

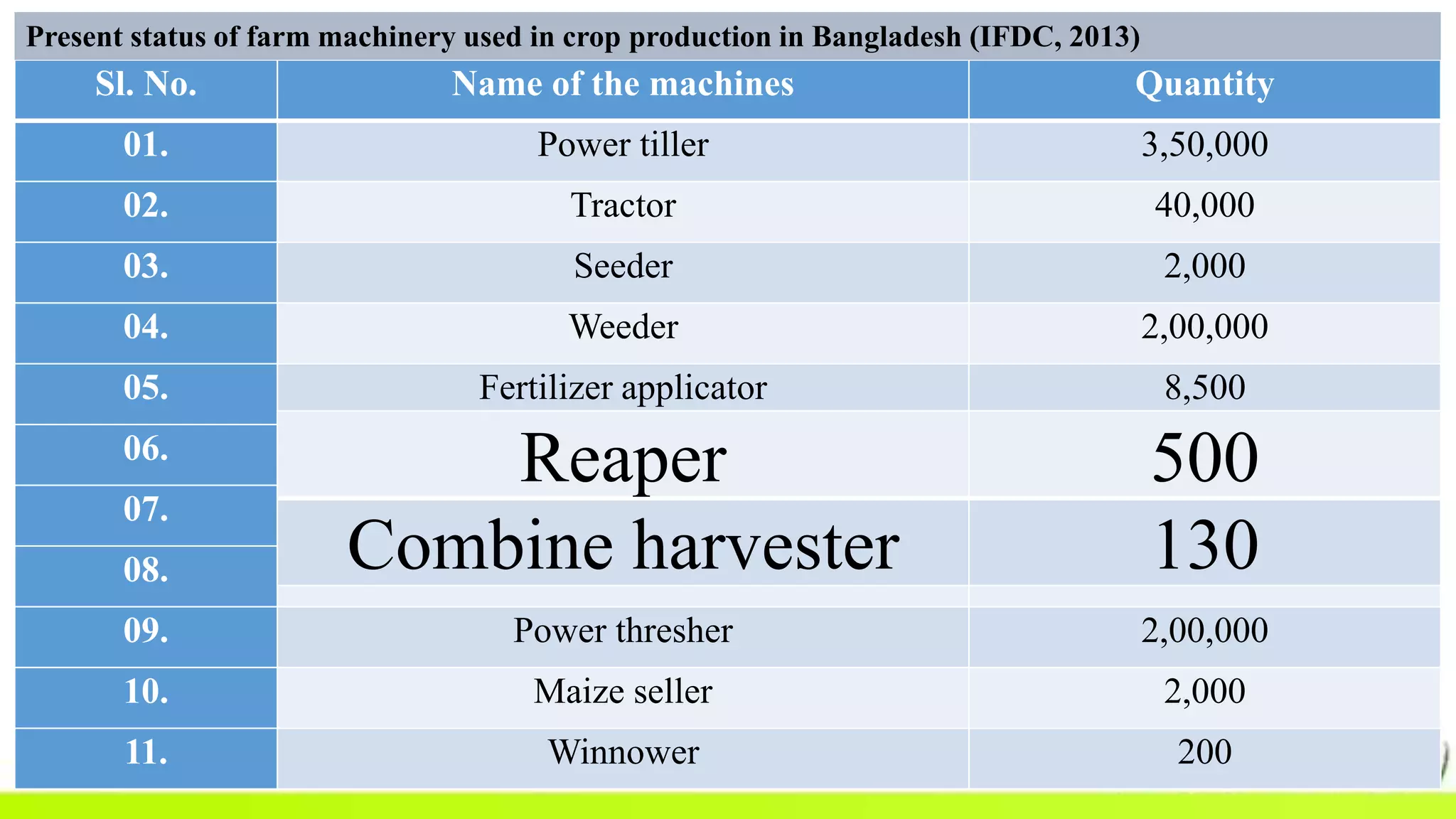

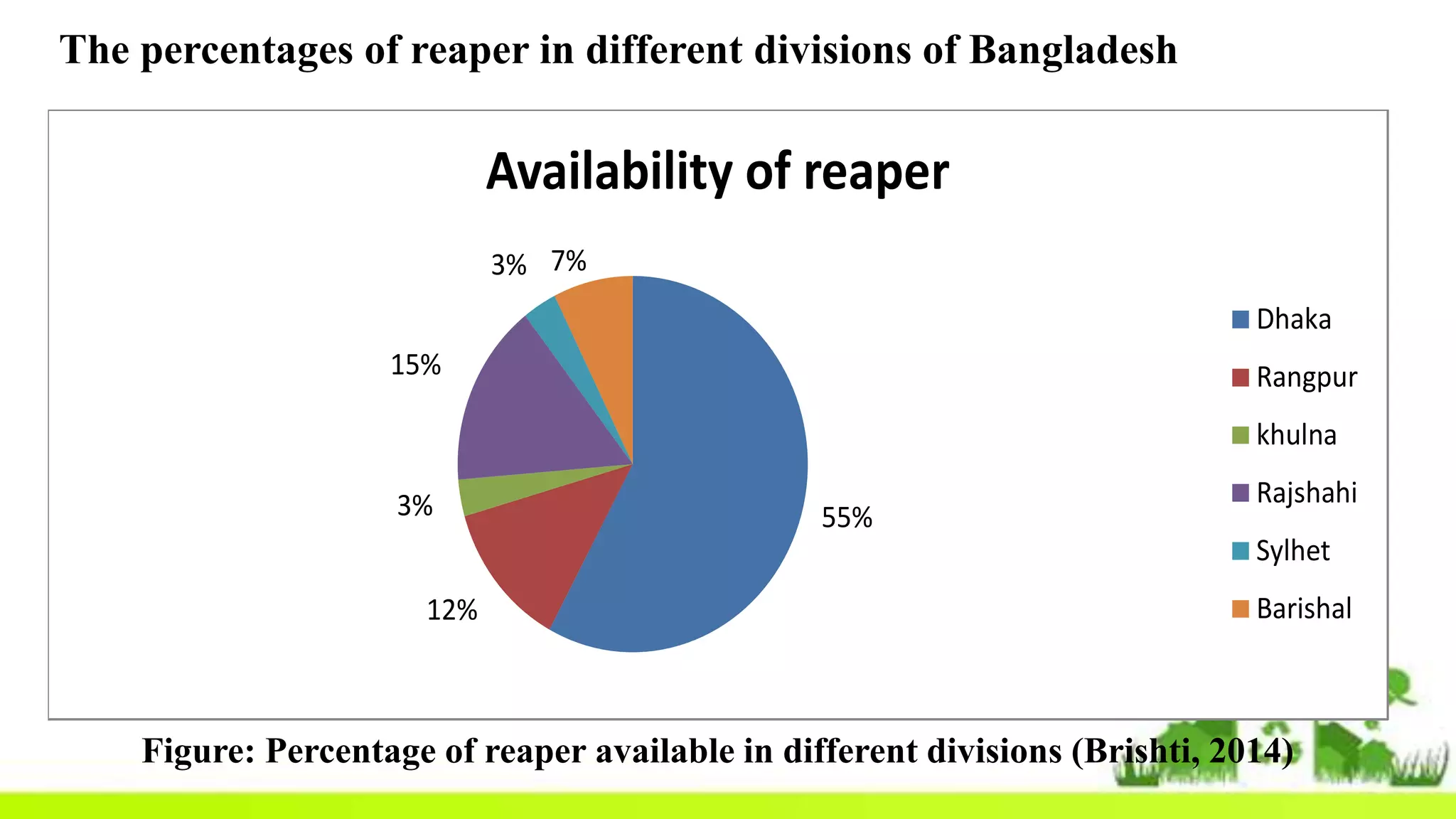

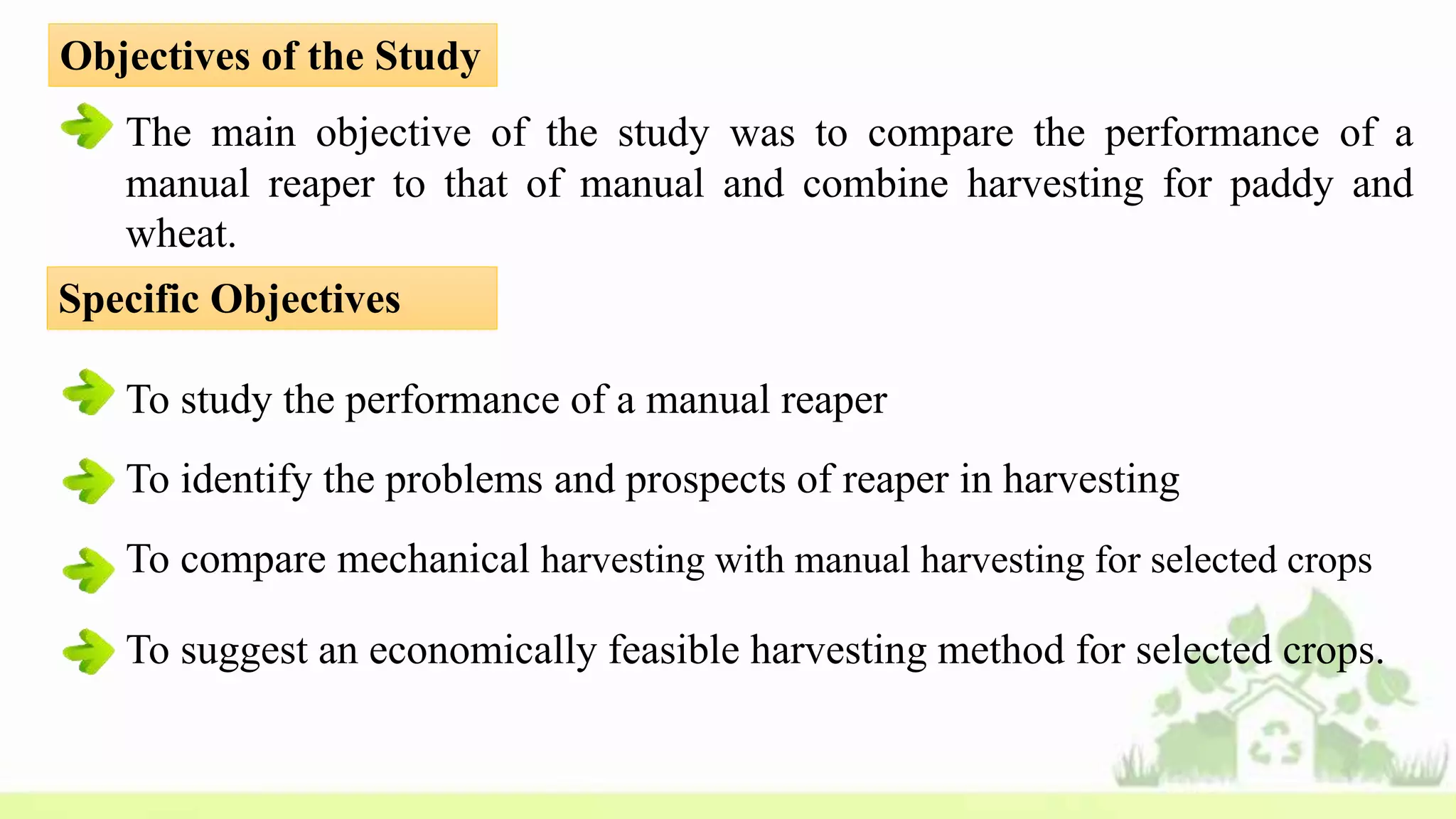

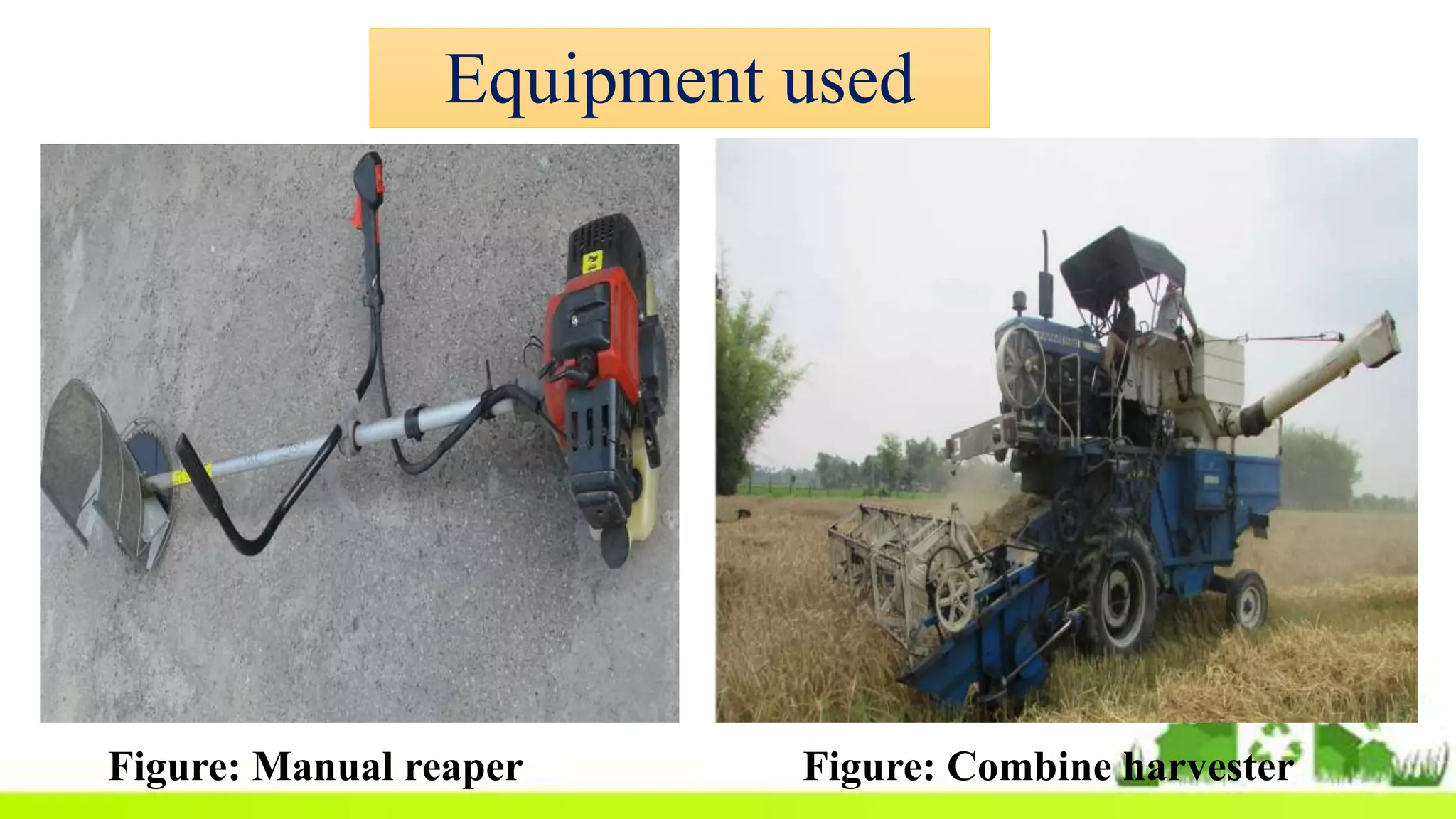

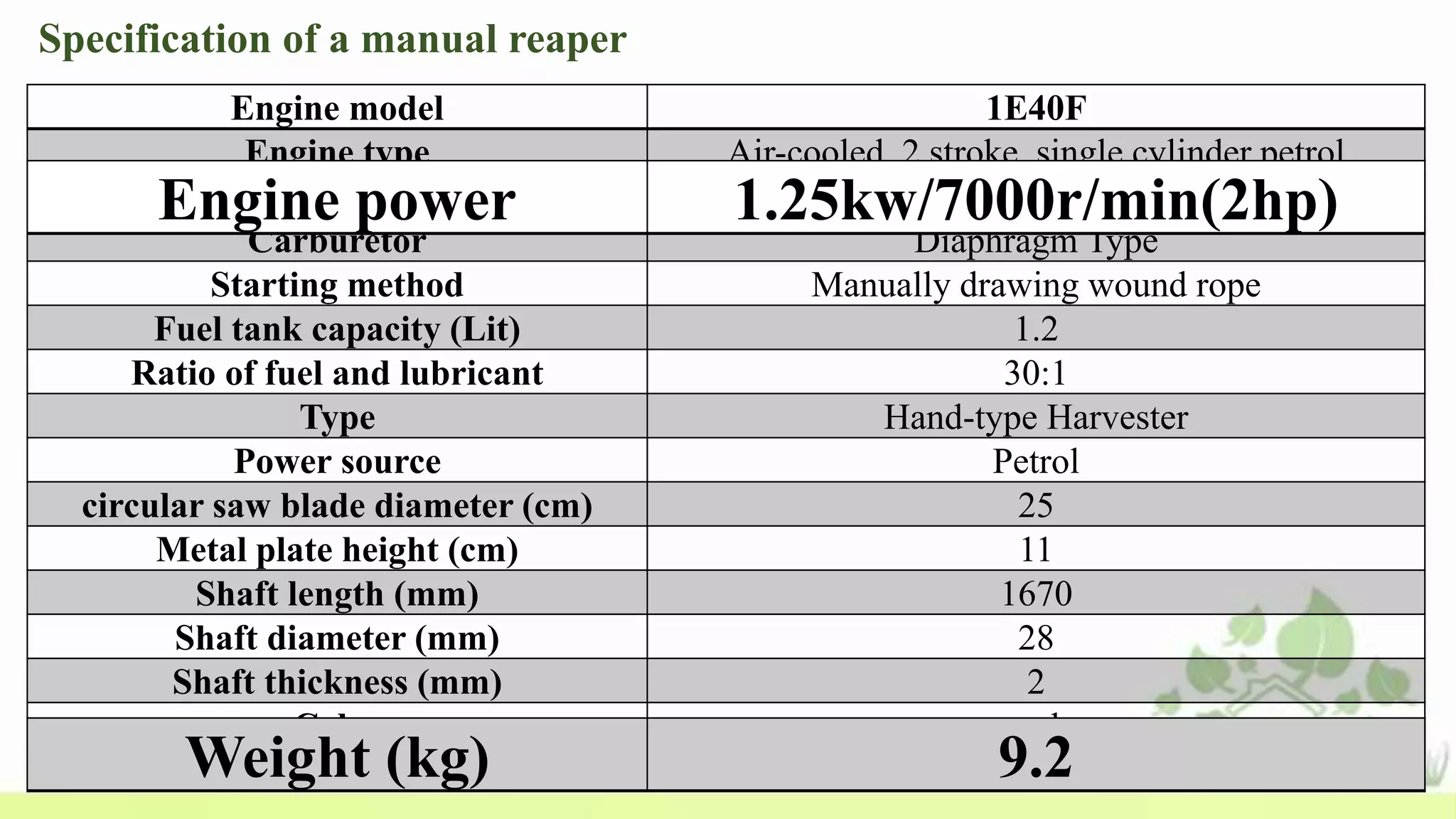

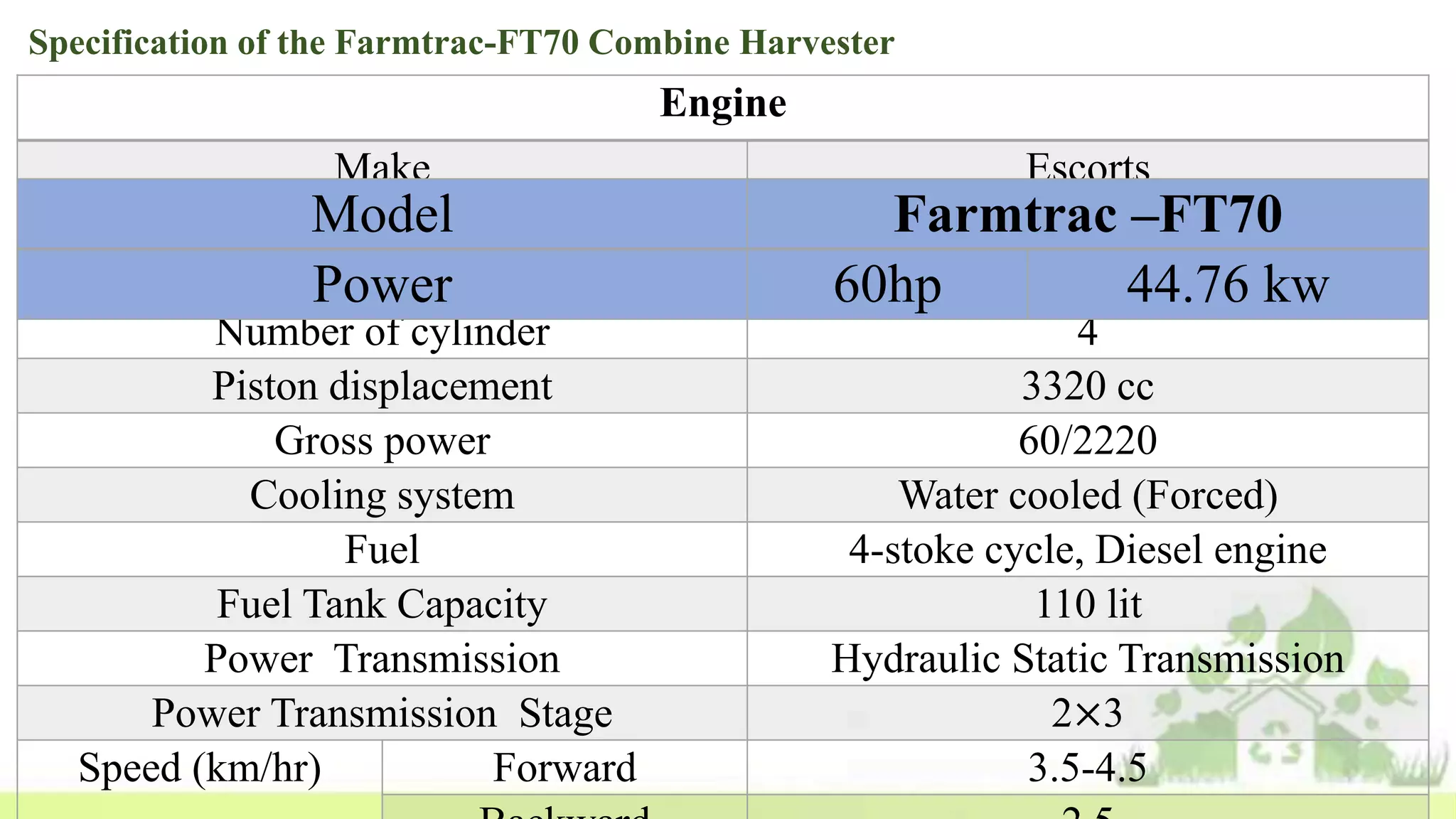

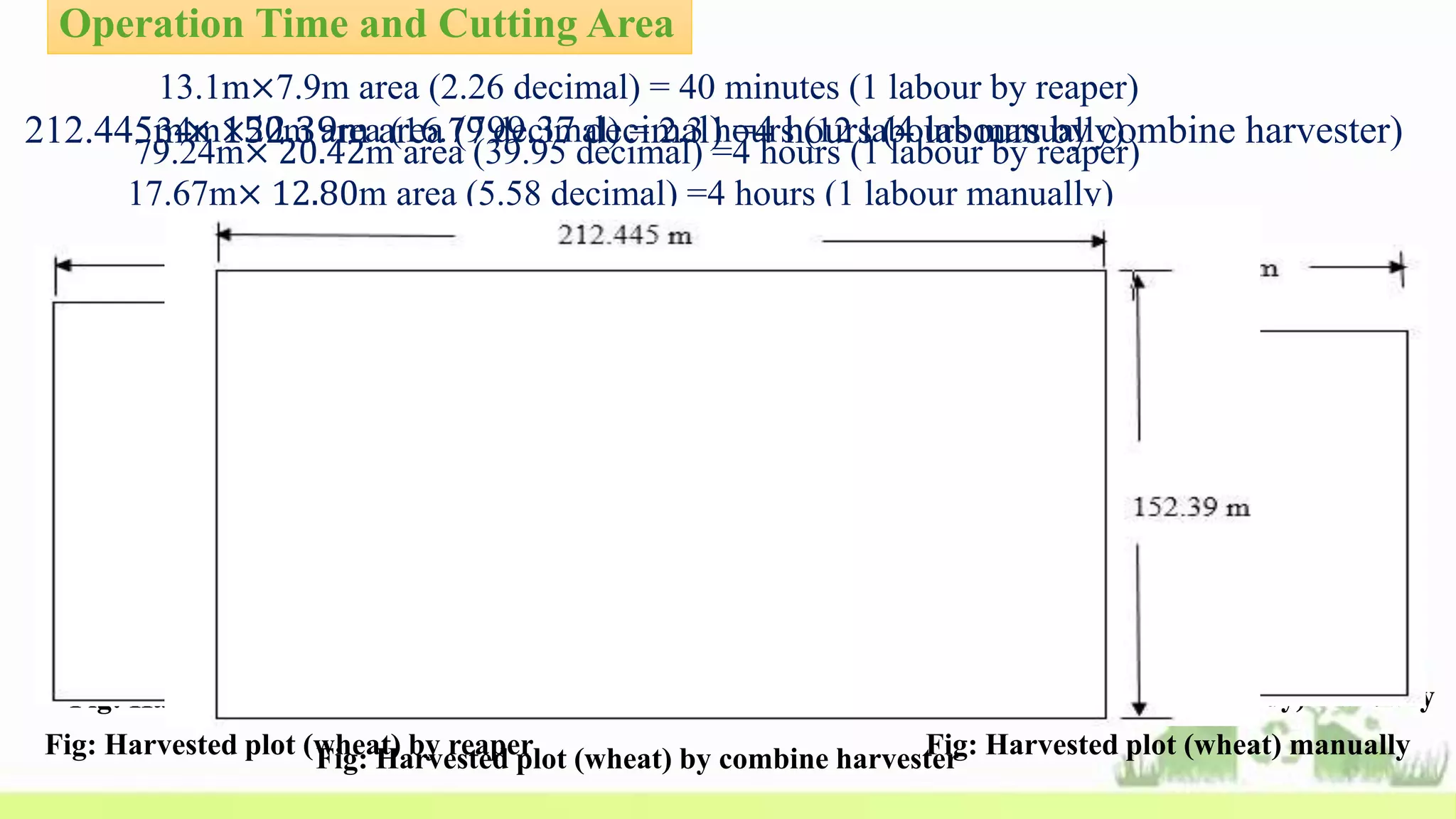

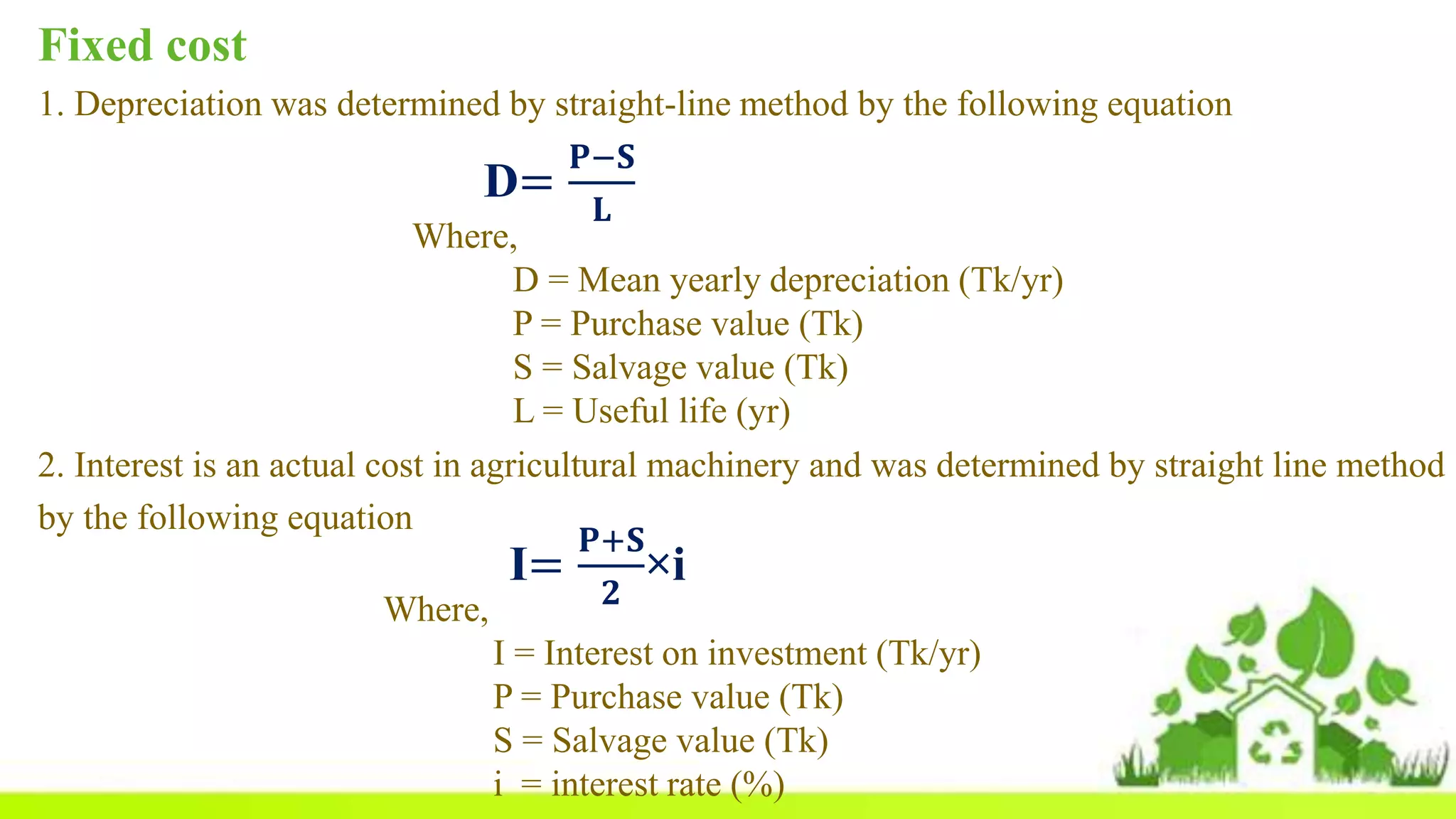

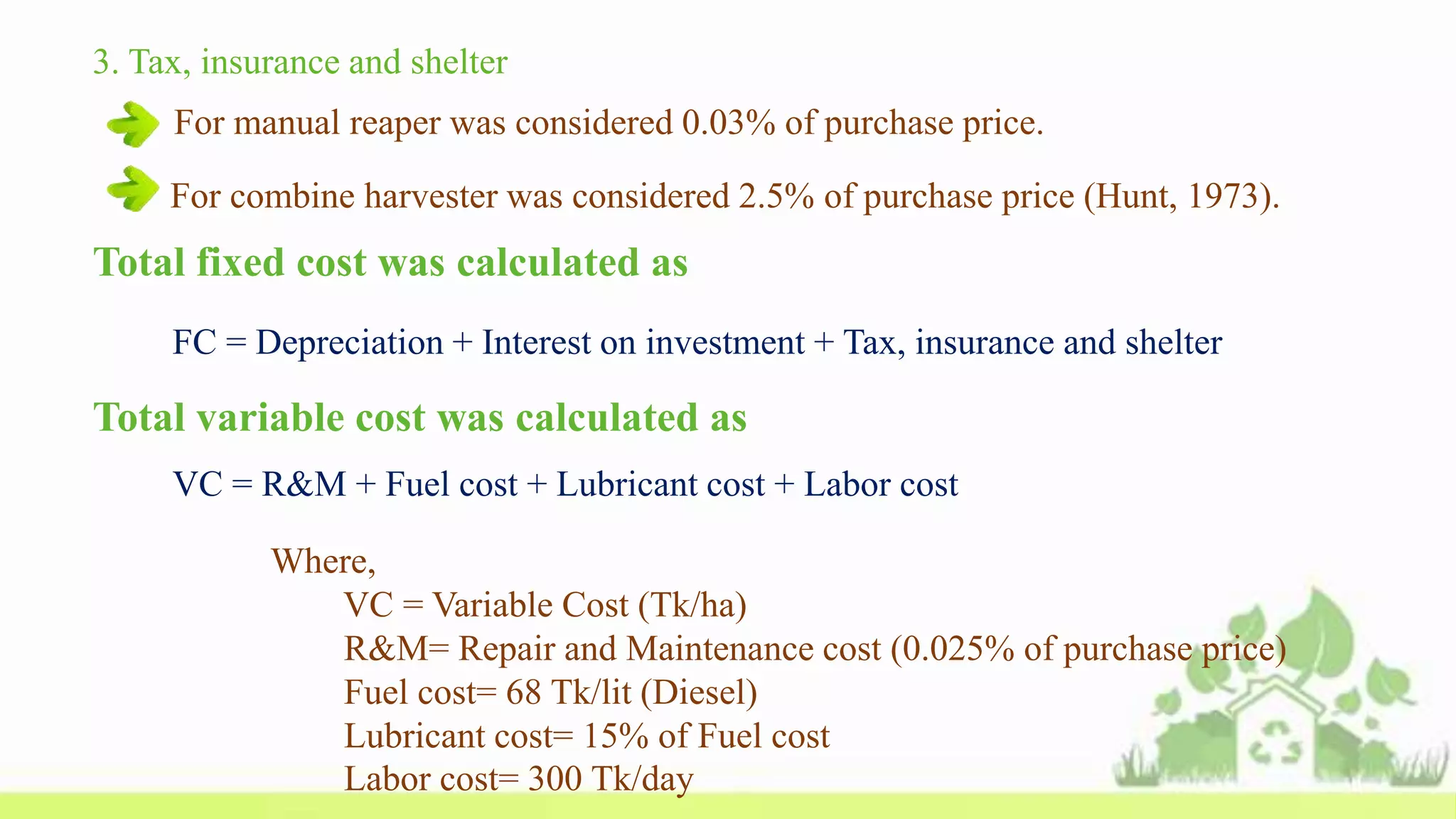

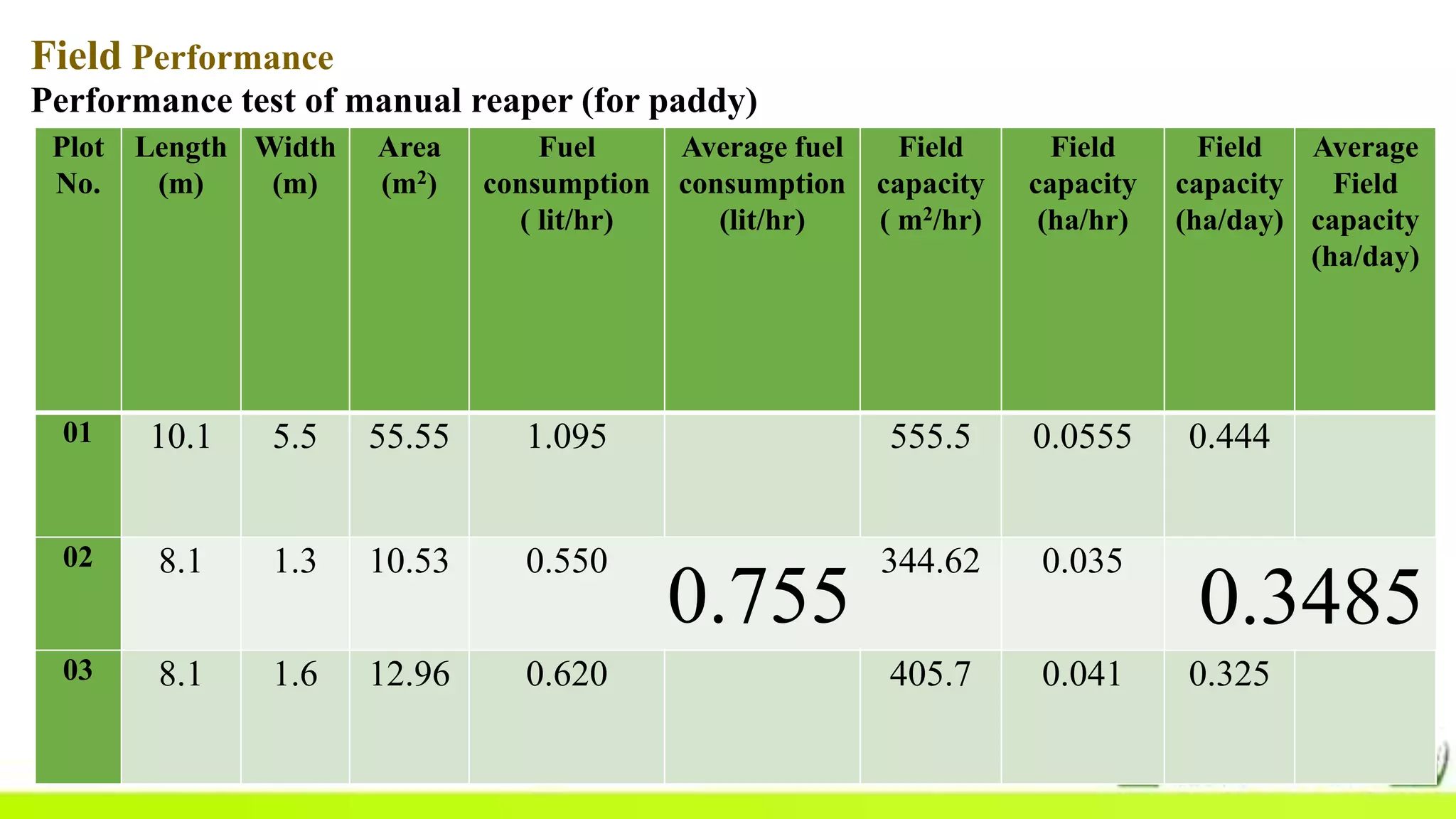

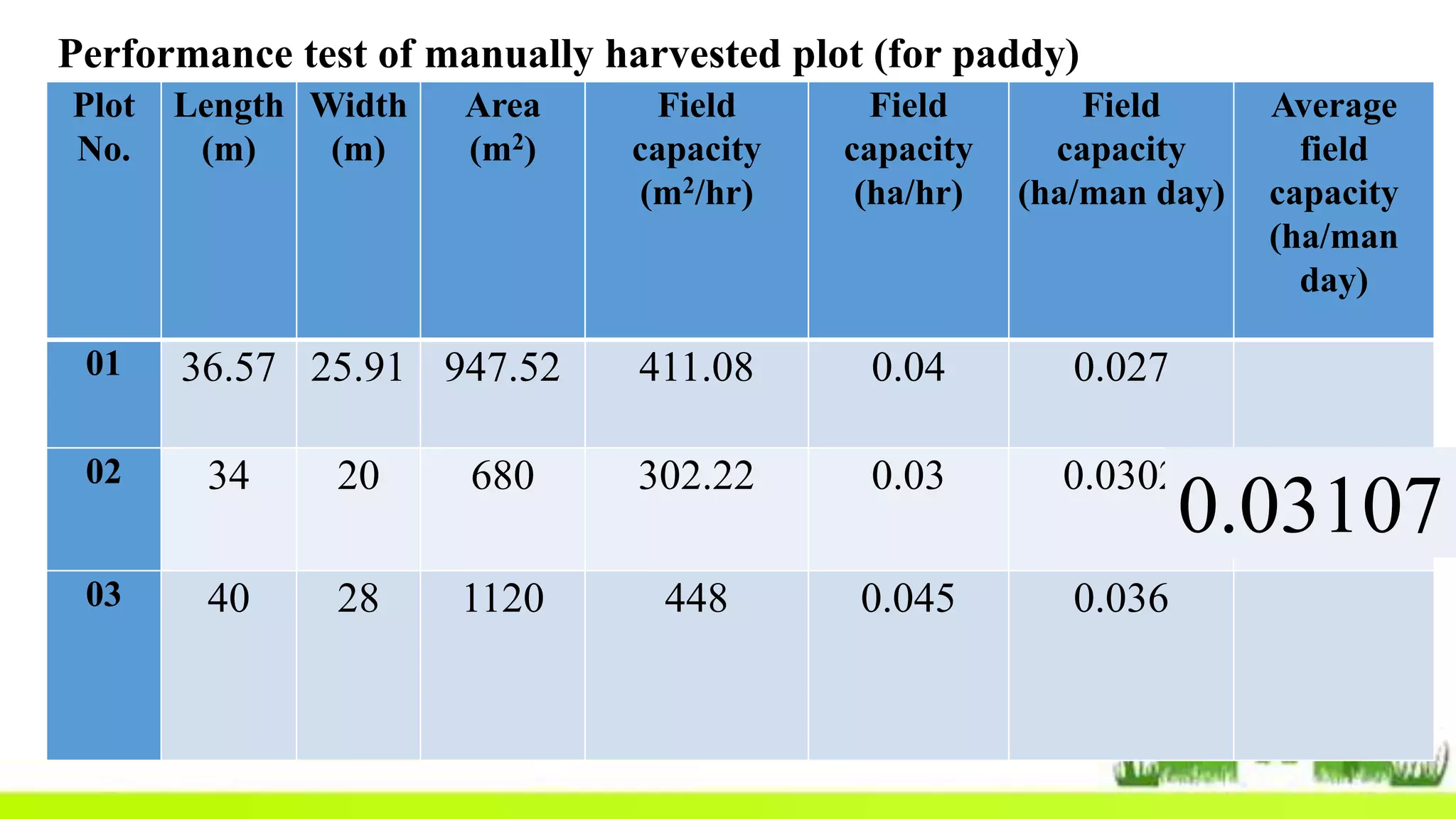

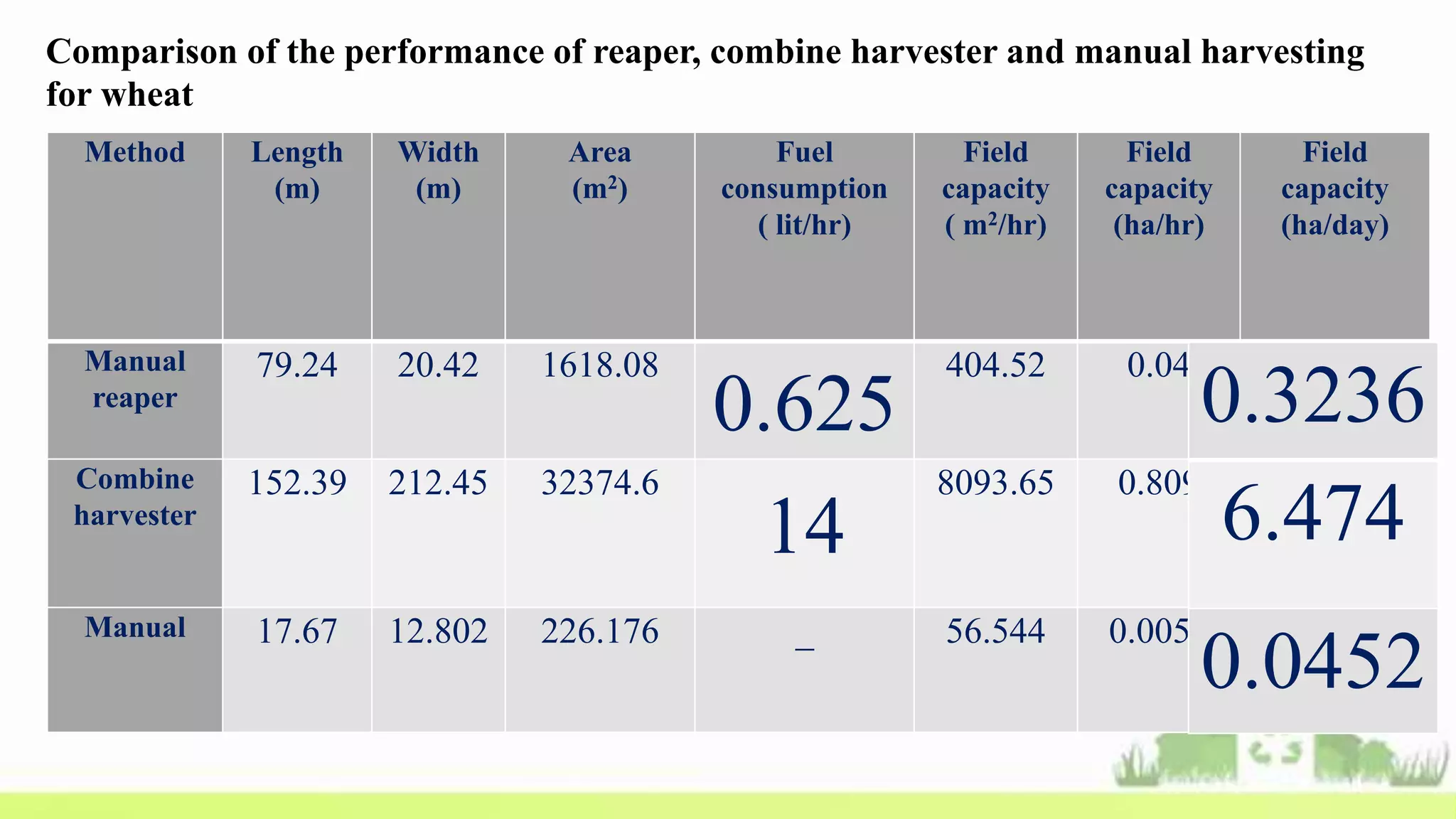

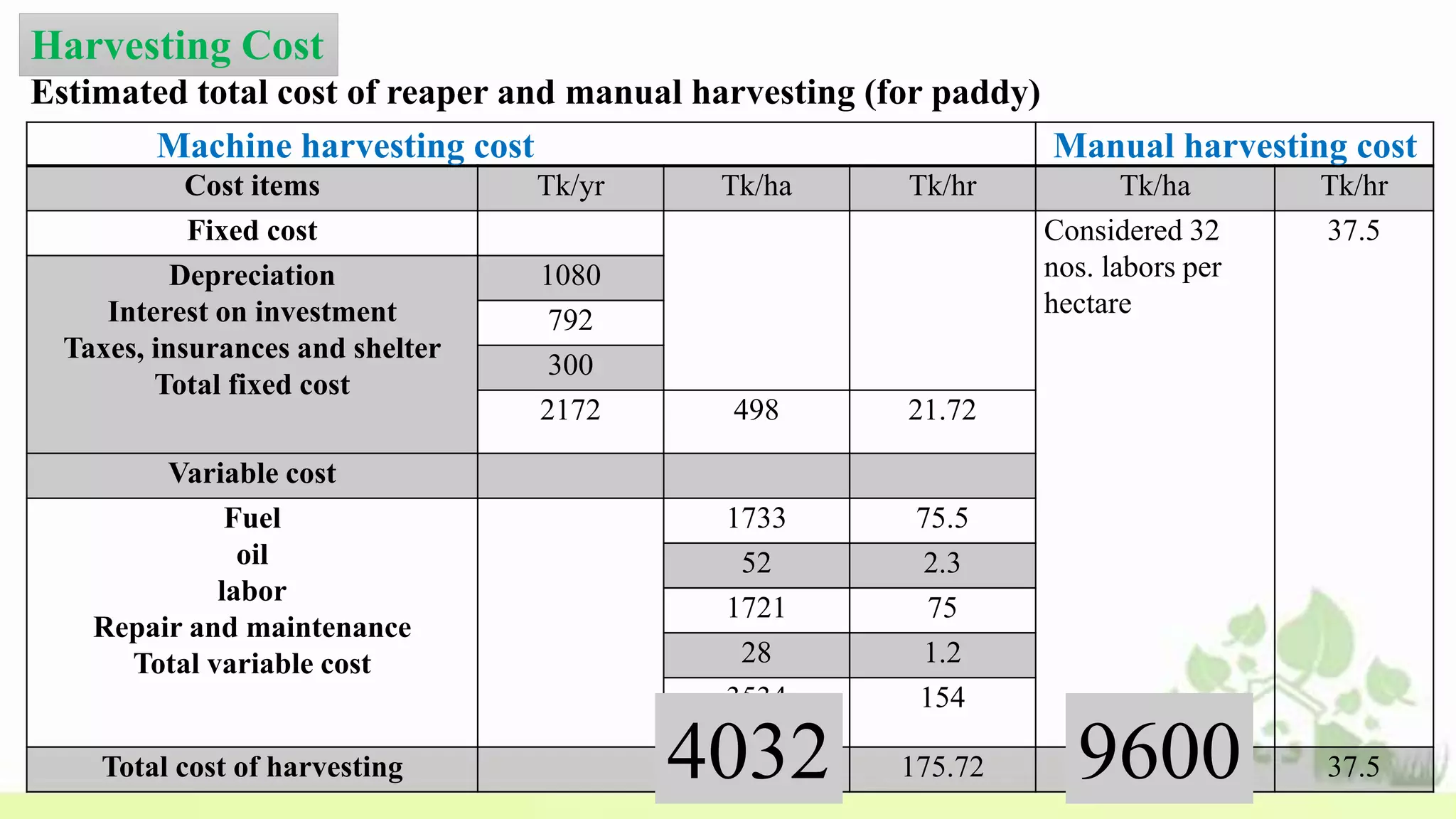

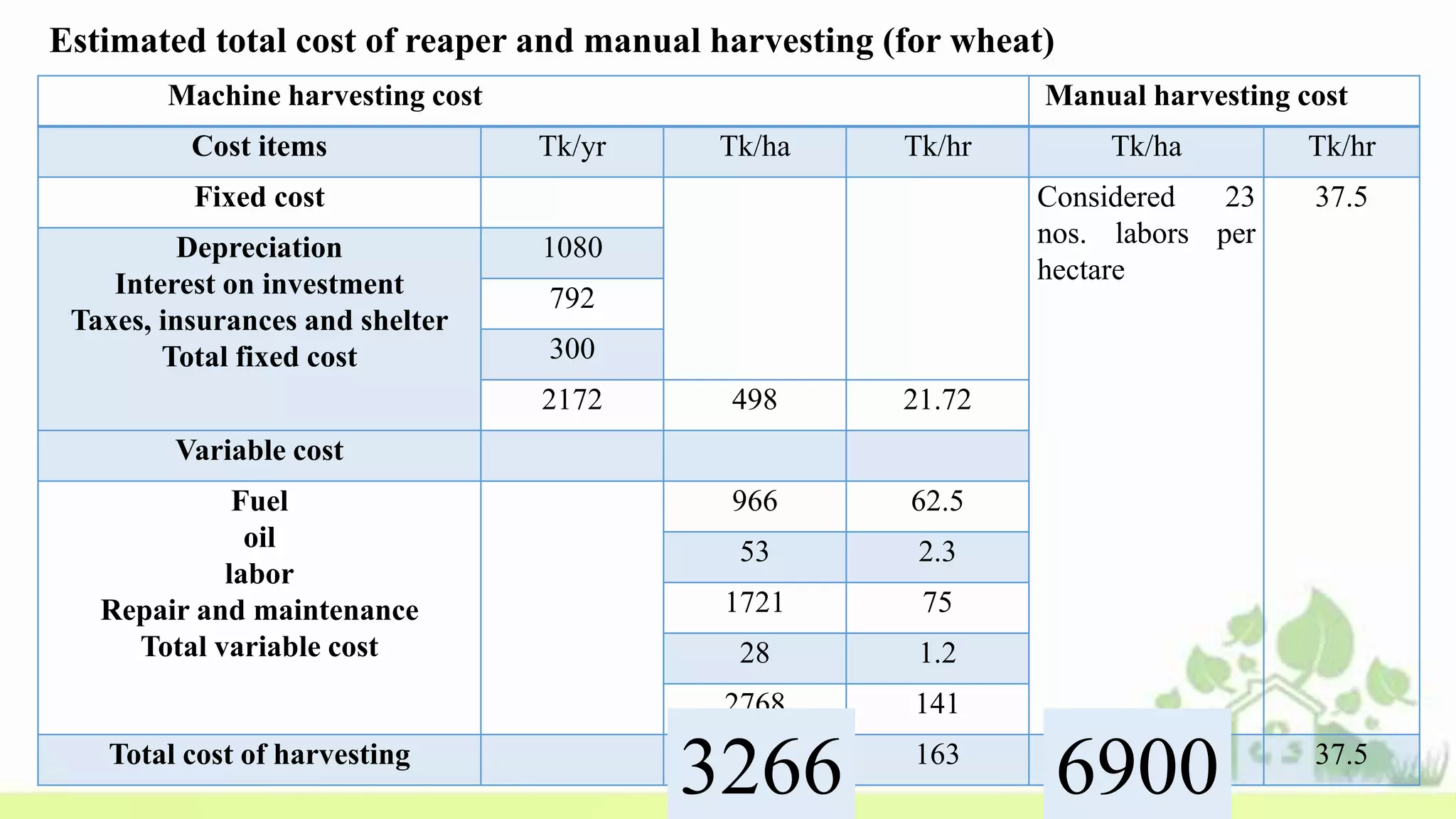

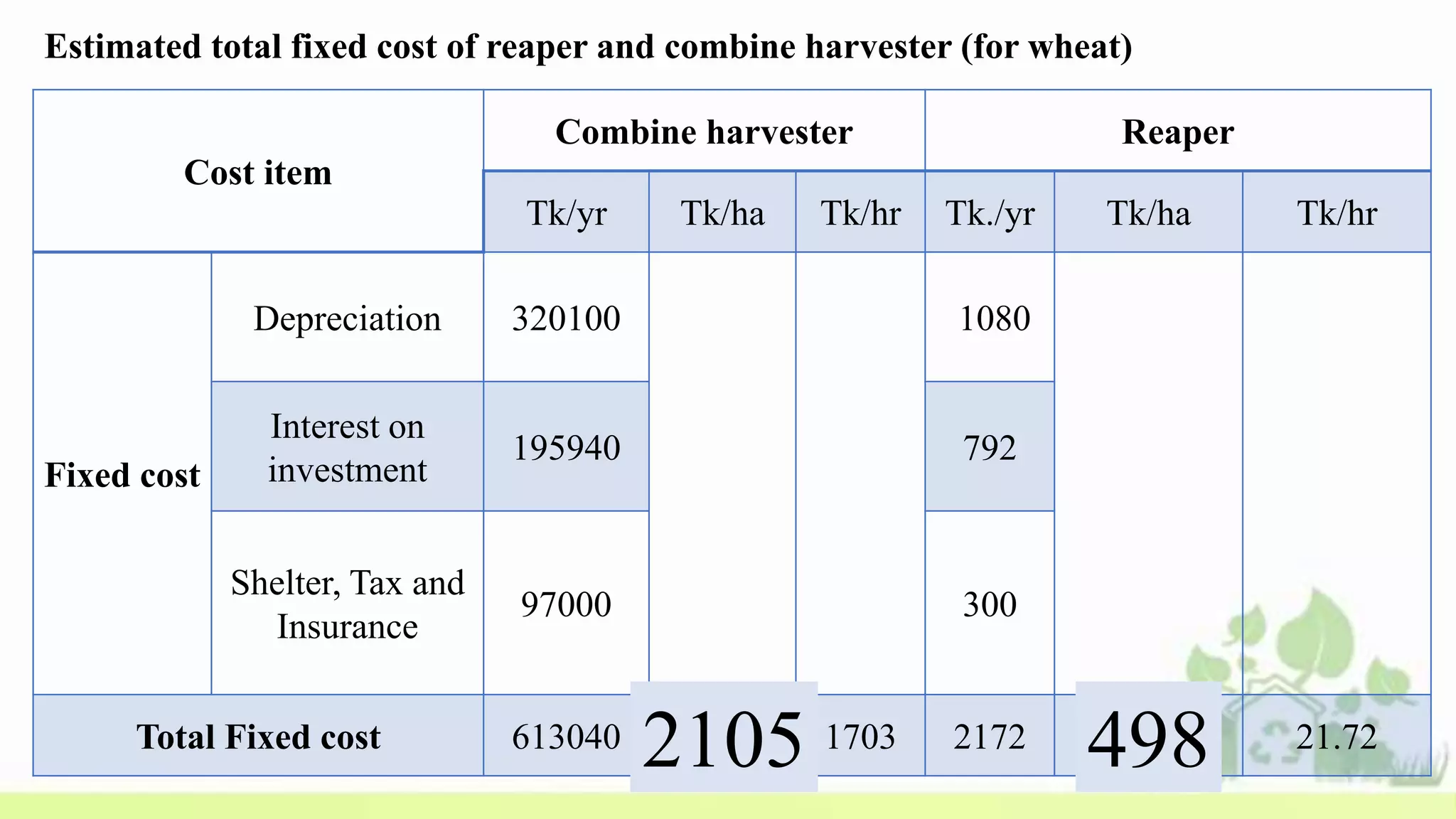

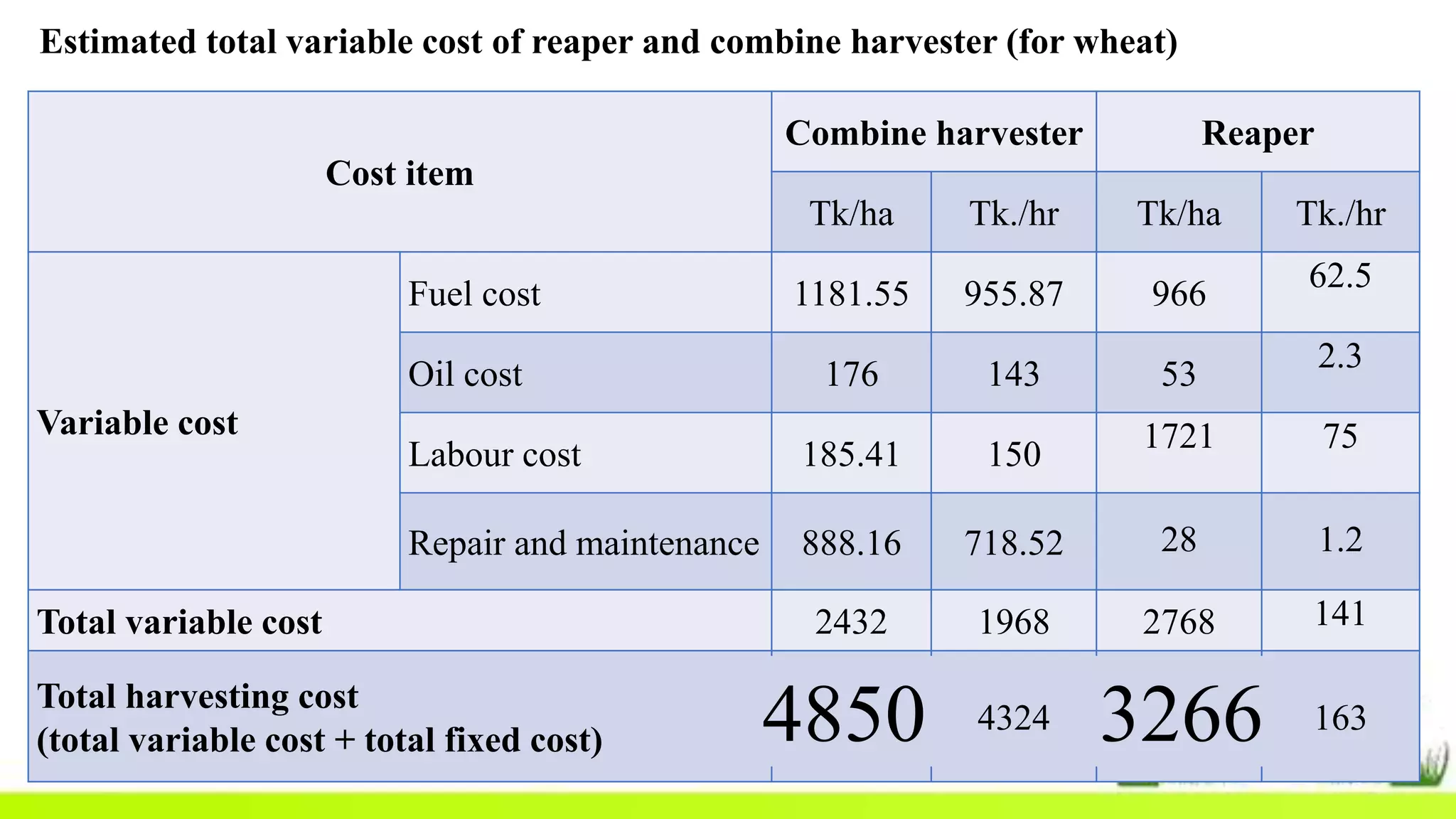

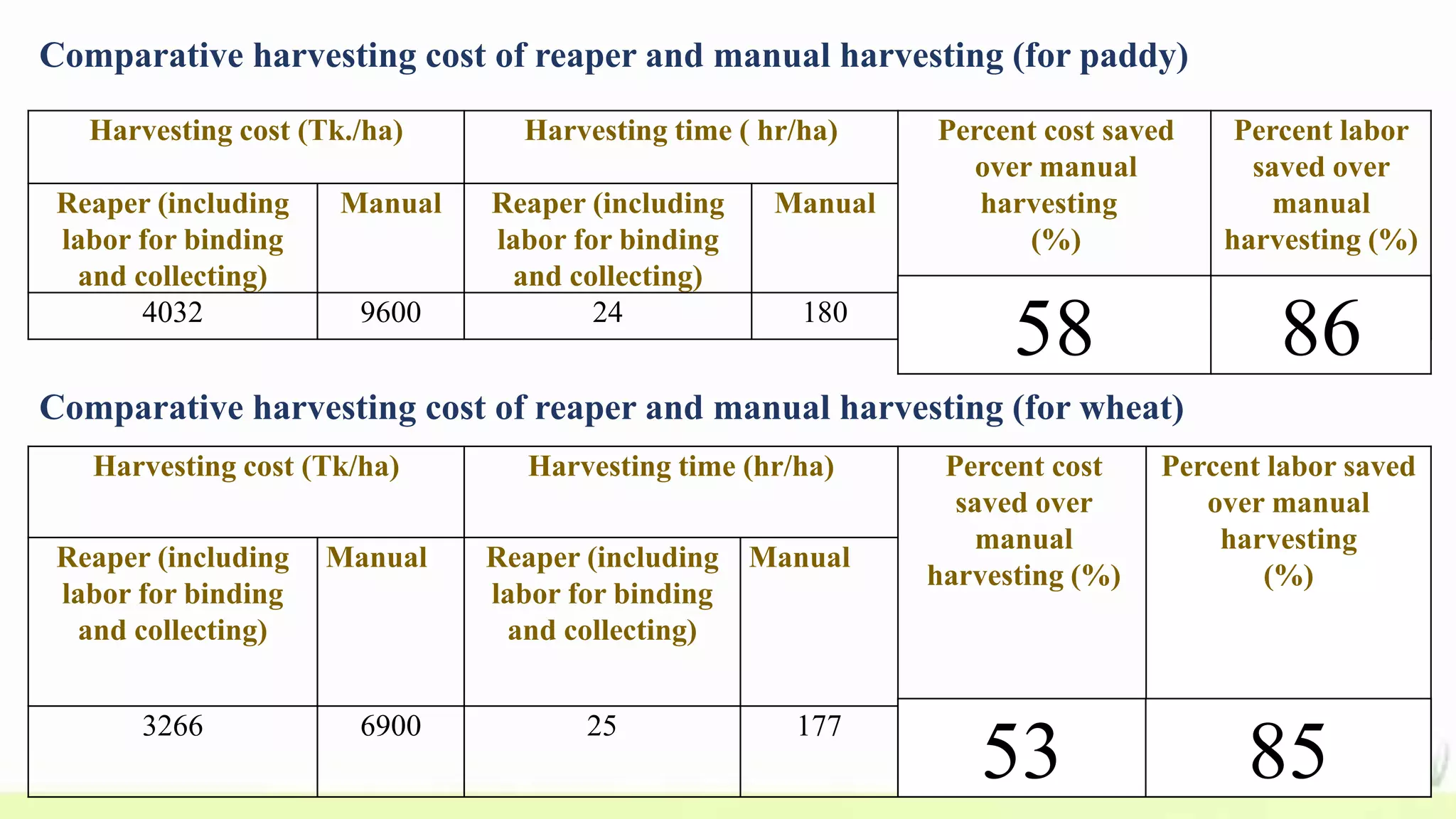

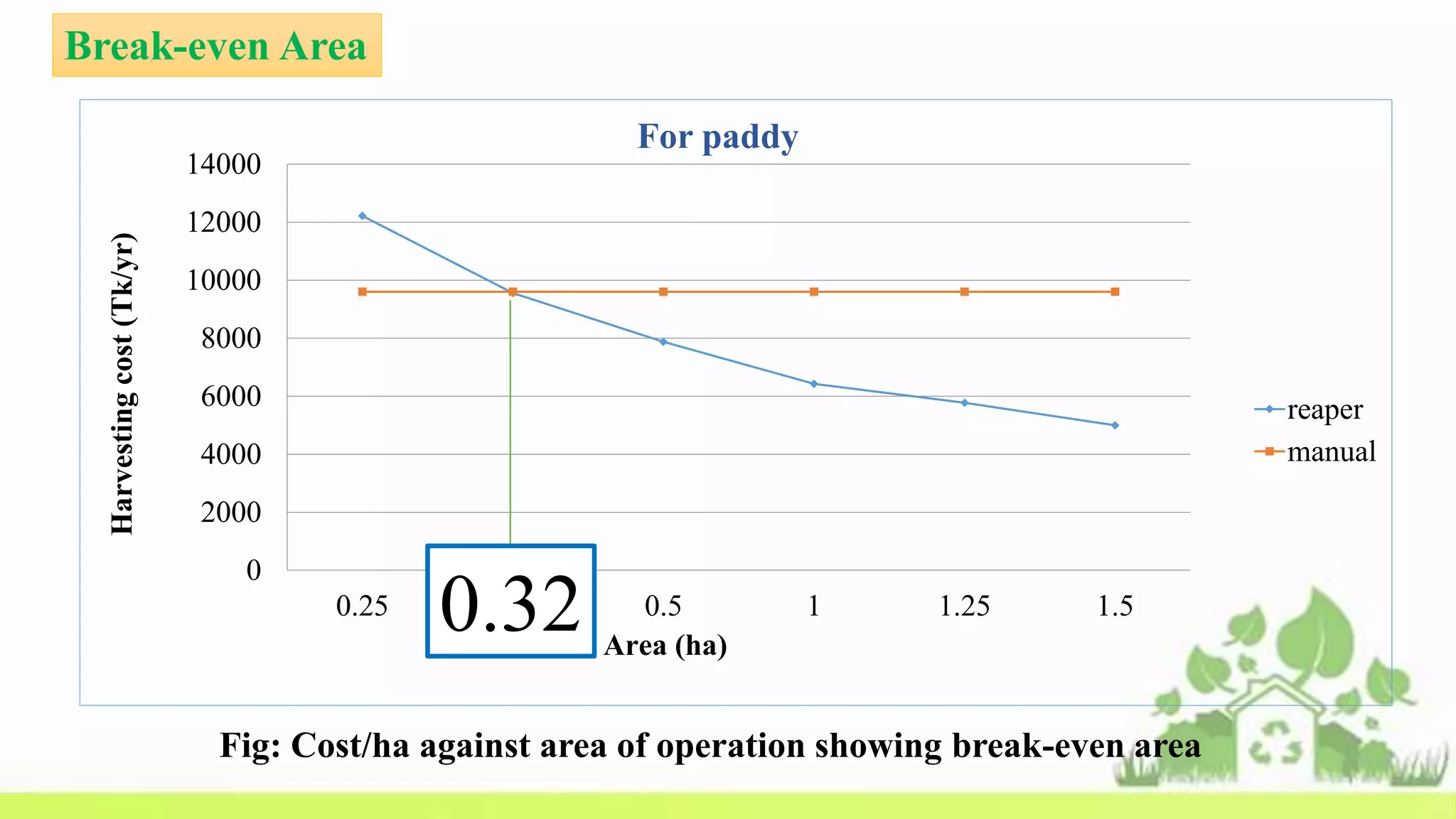

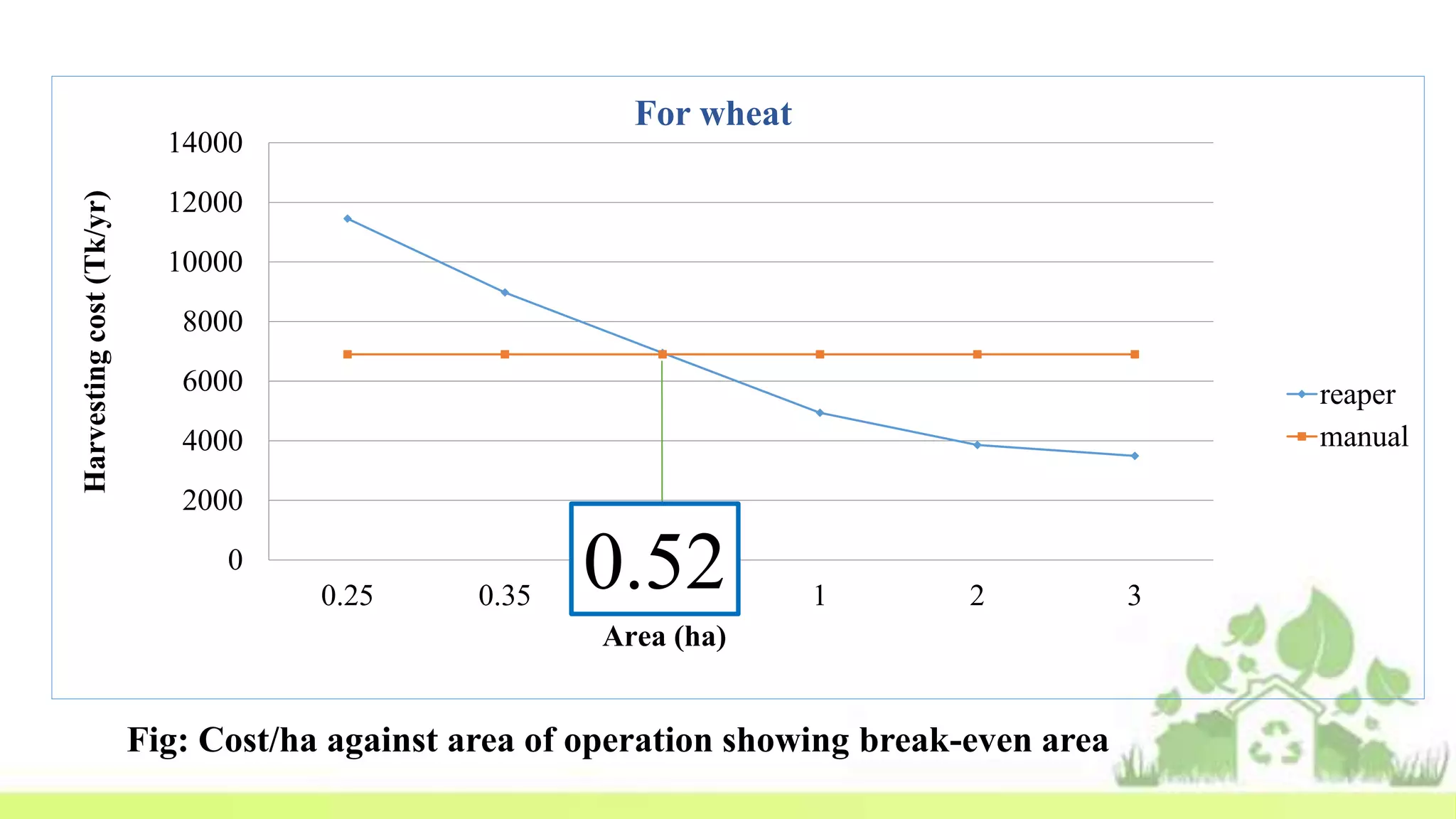

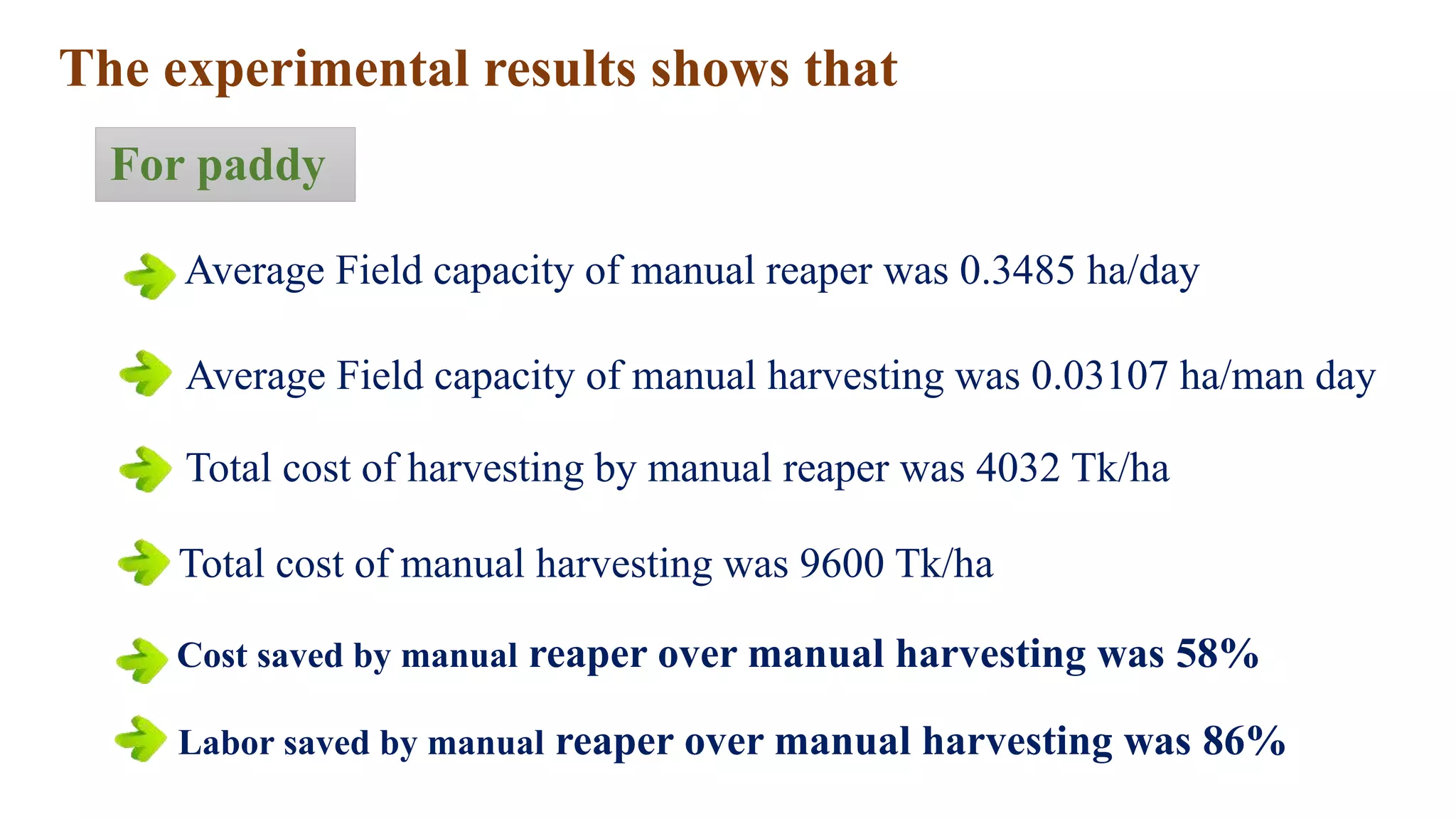

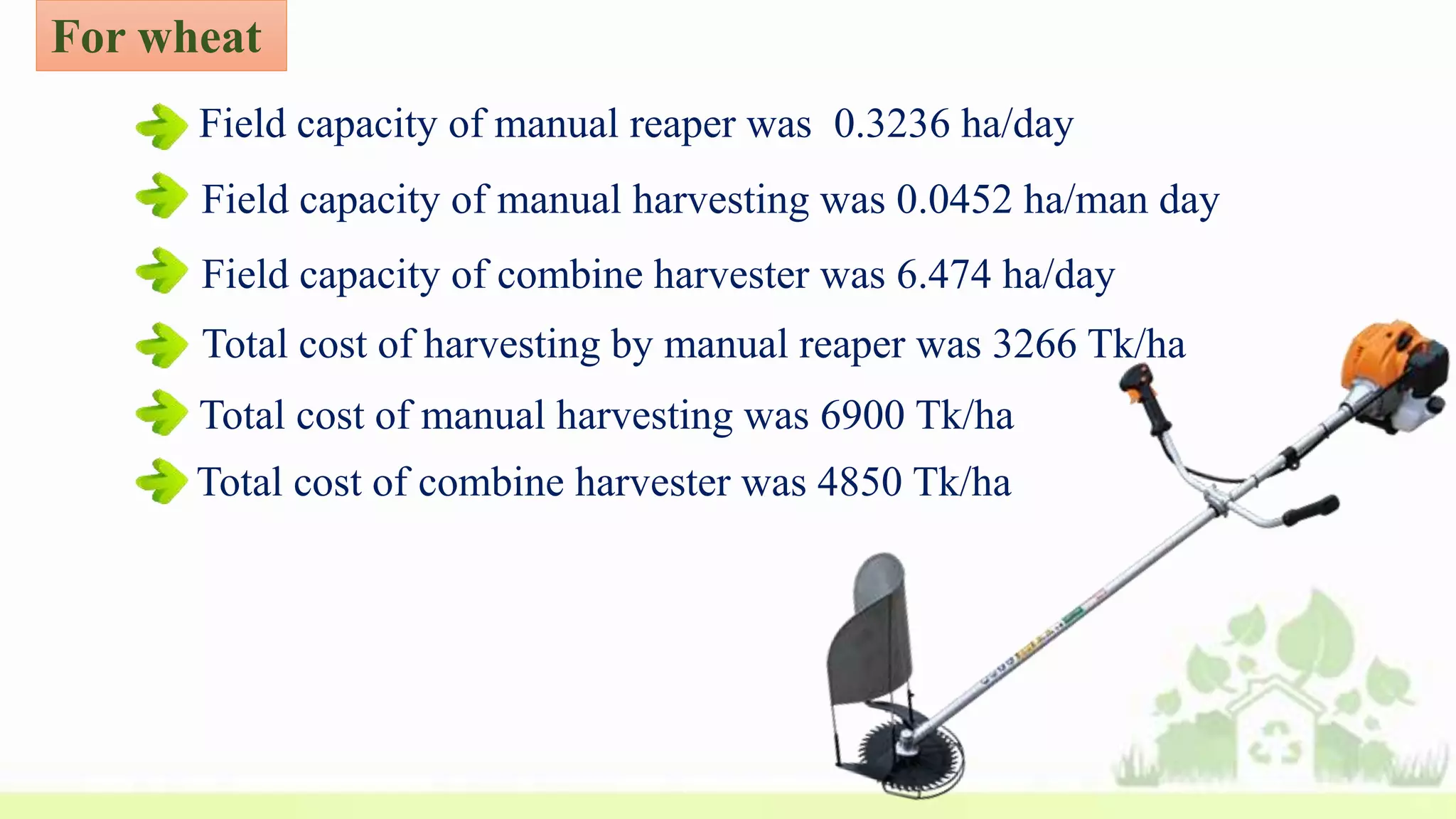

The document presents research comparing the performance and costs of manual reaping, combine harvesting, and manual harvesting of rice and wheat in Bangladesh. It describes the equipment, experimental methodology including plot sizes and locations, and results including fuel consumption, field capacity, and cost analysis of the different harvesting methods. The findings indicate that combine harvesting has the highest field capacity and lowest costs, while manual harvesting has the lowest field capacity and highest costs.