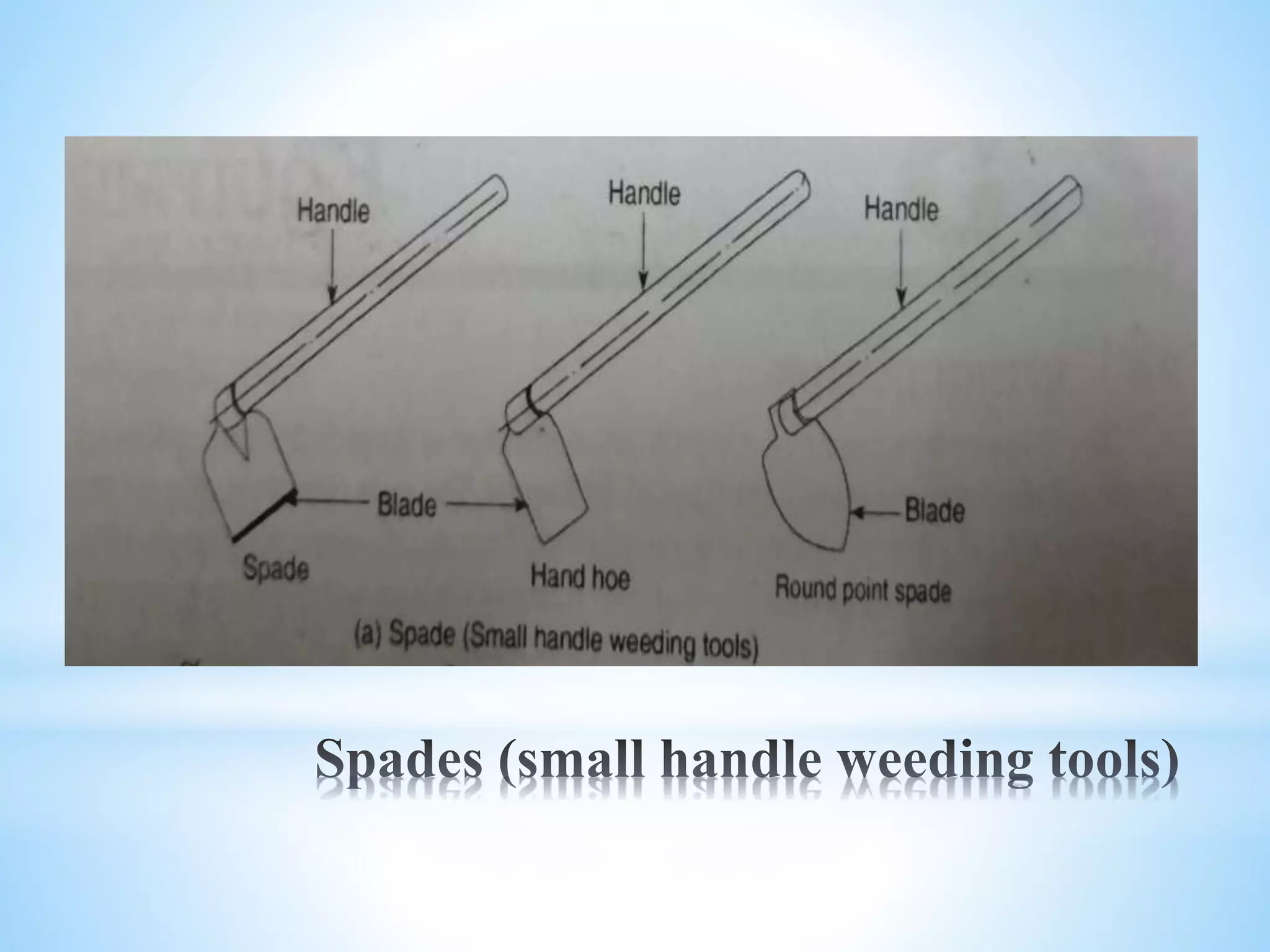

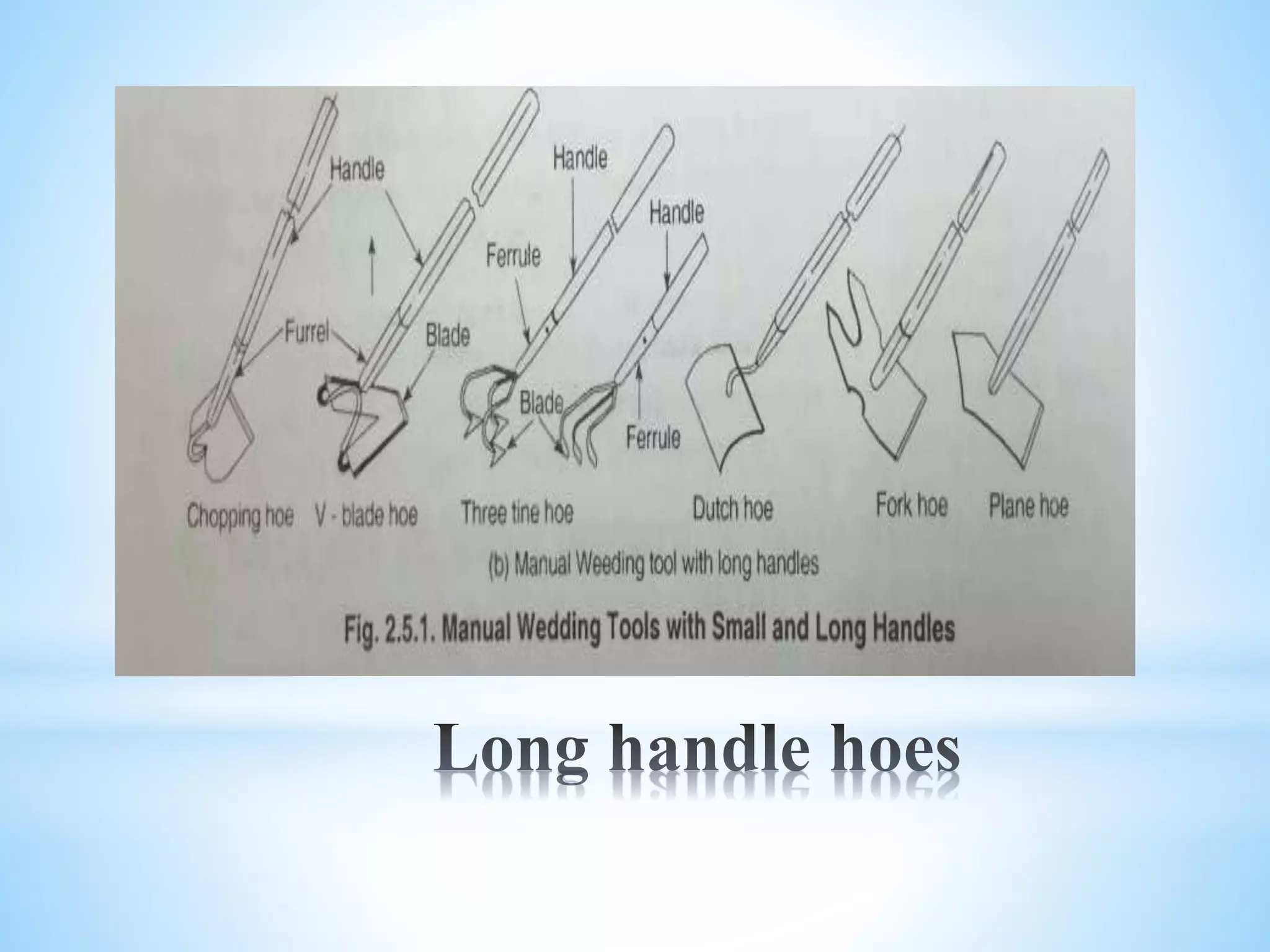

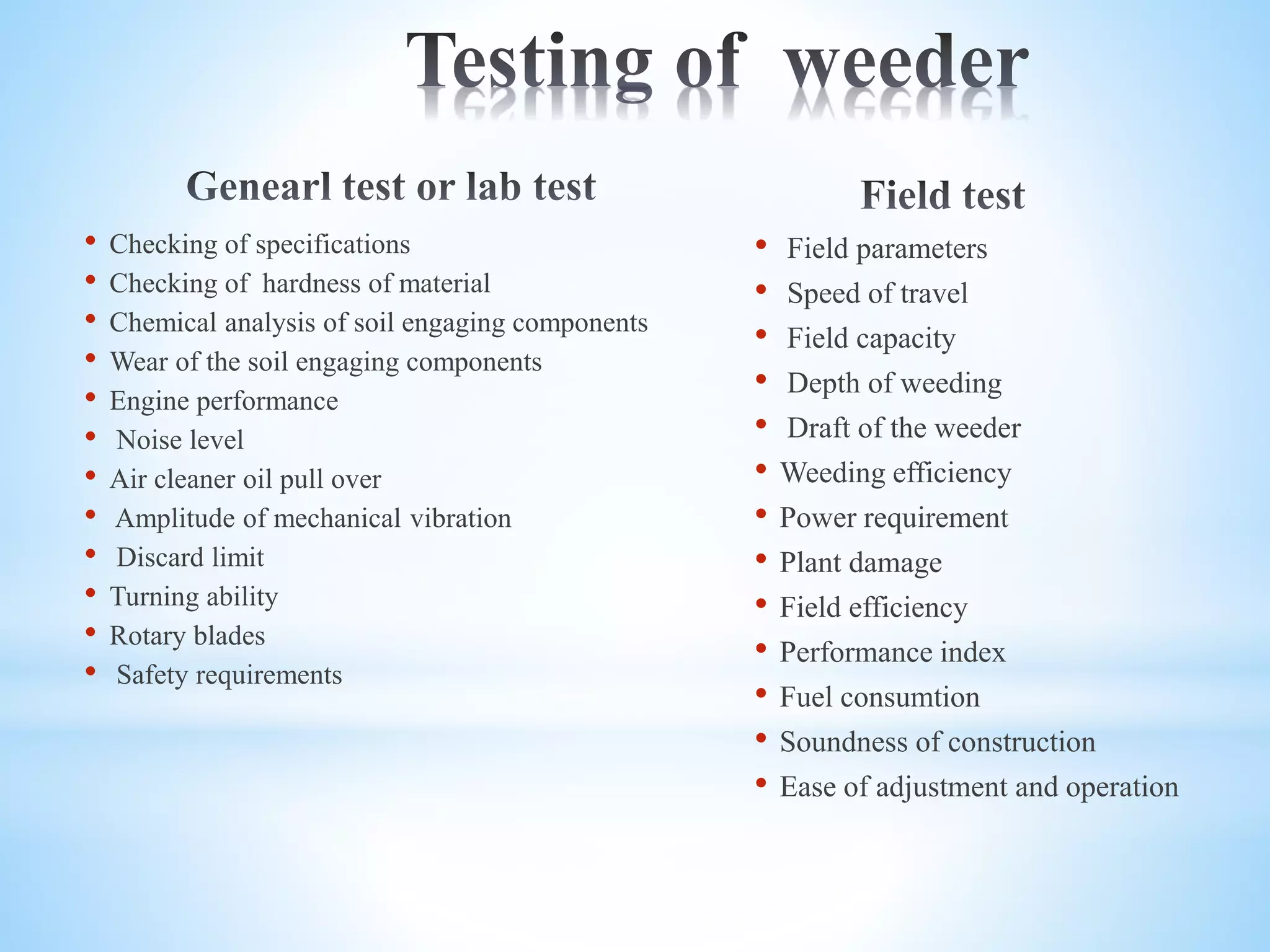

The document discusses the testing of manual and power-operated weeders, emphasizing their importance in reducing competition among crops and improving soil conditions. It outlines various types of weeders, the testing parameters such as specifications, performance, efficiency, and safety requirements. Additionally, it provides formulas for calculating weeding efficiency, power requirements, and other operational metrics.

![Power requirement

The power input required for weeding operation is calculated by

considering the parameters like draft and traveling speed.

Power input (hp) = [draft(kg) × travelling speed (m/s)]/75

Plant damage

The test is conducted to find out the percent of the plant damage that taken

place during the field operation.

The percent plant damage is calculated by the following expression

Percentage plant damage = q/p × 100

where, q= Number of plant damaged in 10 m row length after weeding

p= Number of plant damaged in 10 m row length before weeding](https://image.slidesharecdn.com/weedertestingppt-200116182646/75/Testing-of-manual-and-power-Weeder-19-2048.jpg)