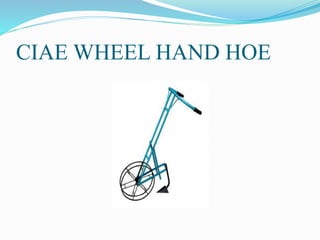

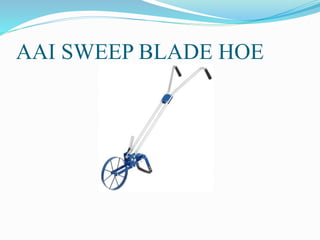

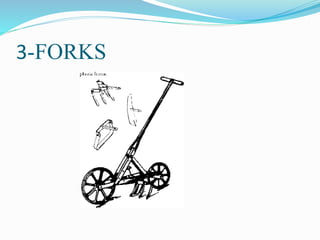

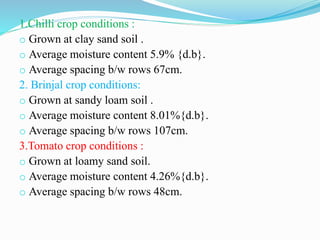

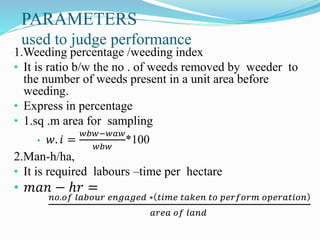

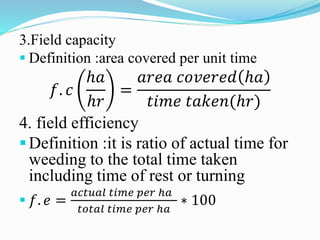

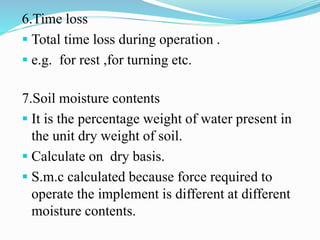

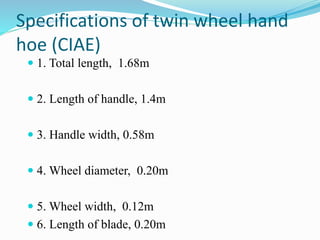

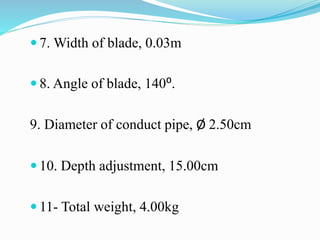

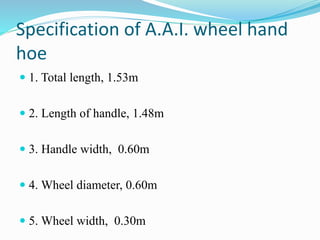

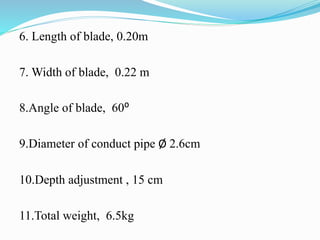

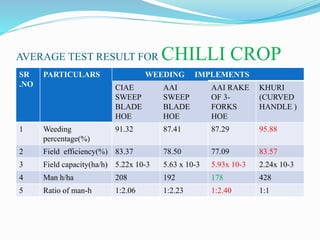

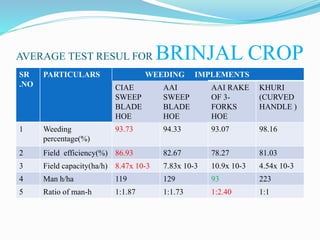

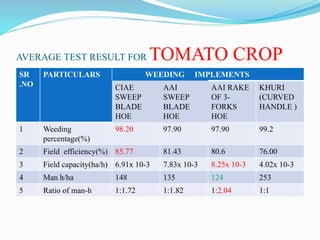

The document presents the results of an experiment comparing the performance of different mechanical weeders to traditional manual weeding for row crops like chili, brinjal, and tomato. The mechanical weeders tested included wheel hand hoes from CIAE and AAI, as well as a traditional khurpi. The experiment found that the CIAE wheel hoe had the highest average weeding efficiency and field efficiency, while the AAI wheel hoe with three forks had the highest field capacity and lowest man hours per hectare. Overall, the mechanical weeders performed better than manual weeding and the CIAE and AAI wheel hoes were both effective options, with CIAE performing best for weeding percentage and AAI's