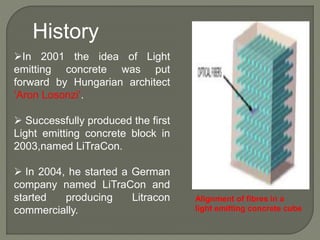

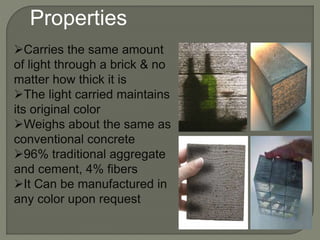

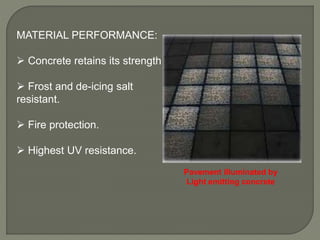

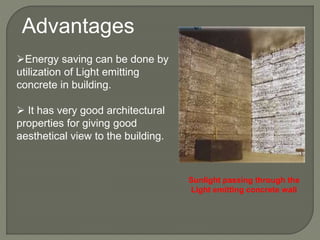

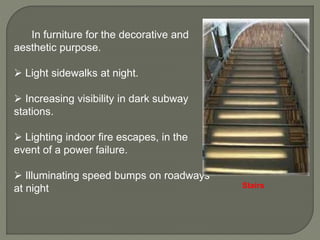

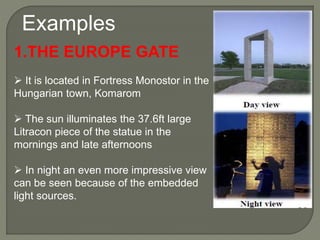

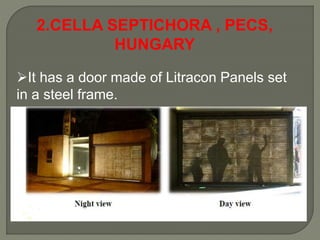

This document discusses light emitting concrete, which is a concrete building material that emits light through uniformly distributed optical fibers. It works on the principle of nano-optics, where fibers placed directly on top of each other act like slits to carry light through the material. The document outlines the history, properties, manufacturing process, advantages and disadvantages of light emitting concrete. Examples of its applications in buildings, sidewalks, and furniture are also provided.

![Light Emitting Concrete

Presented by

Shaik.Asif.Ahmed [ASIF’ASHU]](https://image.slidesharecdn.com/lightemittingconcrete1-180222145446/85/Light-emitting-concrete-OR-Translucent-concrete-1-320.jpg)