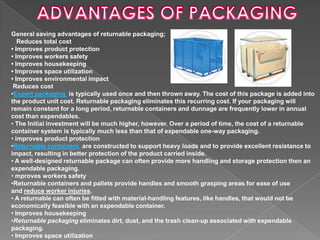

The document discusses the history and evolution of packaging from early natural materials to modern developed materials like plastics and metals. It provides details on the functions of packaging including physical protection, barrier protection, containment, convenience, and security. The document also discusses considerations for package design such as requirements, regulations, sustainability, and relationship to the product and logistics. Key factors in packaging machinery selection and common machinery types are outlined. Advantages and challenges of returnable packaging versus expendable packaging are compared.

![sustainable packaging:

Package development involves considerations for sustainability,

environmental responsibility, and

applicable environmental and recycling regulations. It may involve a life

cycle assessment[16][17] which considers the material and energy inputs and

outputs to the package, the packaged product (contents), the packaging

process, the logistics system, waste management, etc. It is necessary to know

the relevant regulatory requirements for point of manufacture, sale, and use.

The traditional “three R’s” of reduce, reuse, and recycle are part of a waste

hierarchy which may be considered in product and package development.

Waste hierarchy](https://image.slidesharecdn.com/packaging-111124085443-phpapp02/85/Packaging-6-320.jpg)