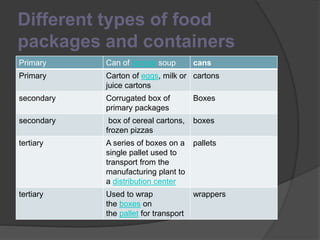

The document discusses food packaging and its effects on the environment. It describes the different types of packaging (primary, secondary, tertiary) and common packaging materials like glass, aluminum, tinplate, paperboard, plastics. Both the advantages and disadvantages of each material are outlined from environmental and economic perspectives. The document also examines how packaging thickness, multi-layer materials, degradability, and recycling impact the environment. It promotes following the 3R hierarchy of reduce, reuse and recycle to minimize packaging's environmental footprint.