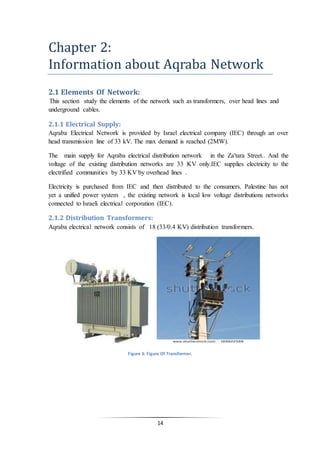

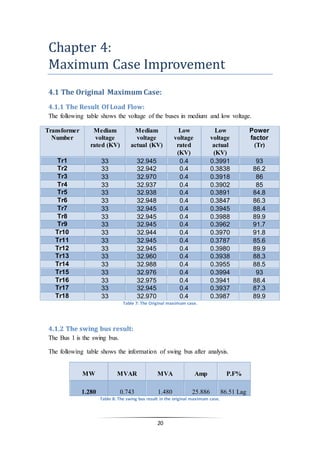

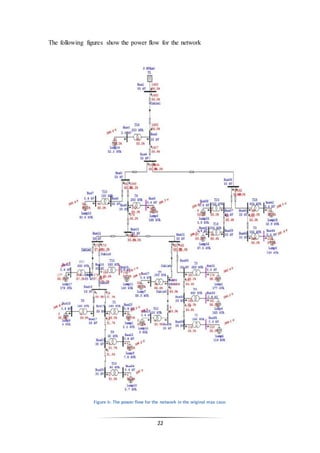

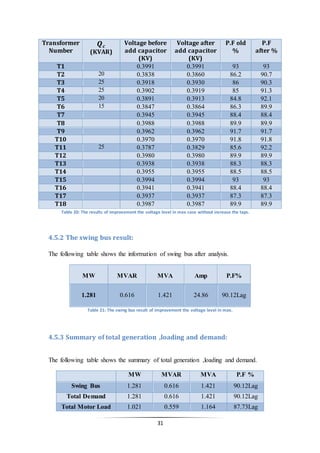

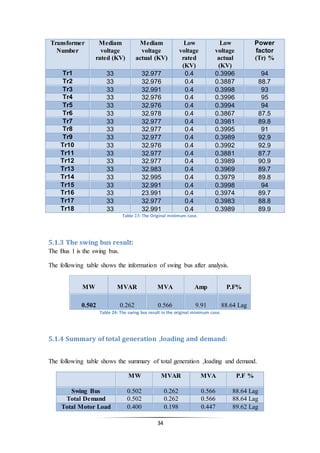

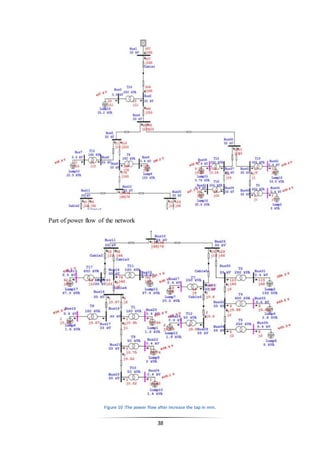

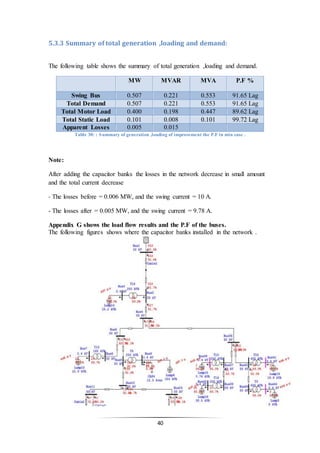

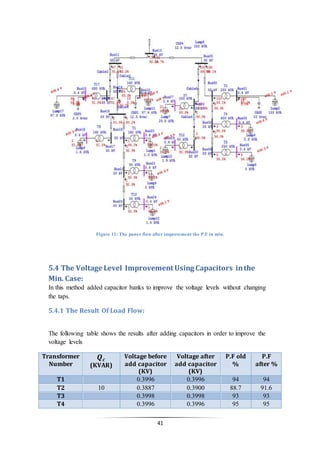

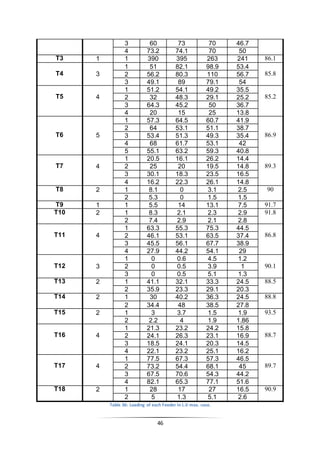

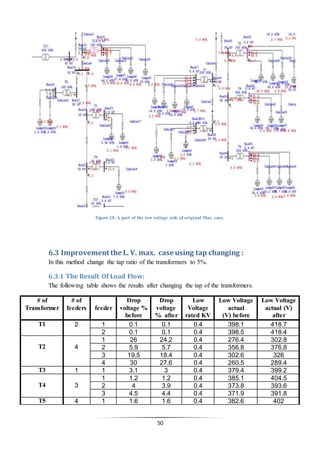

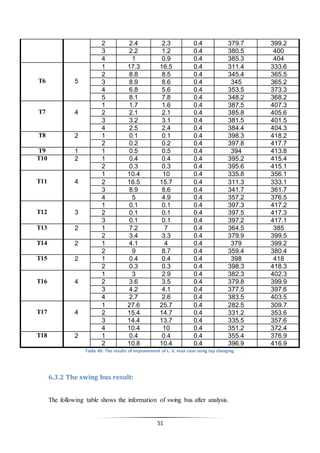

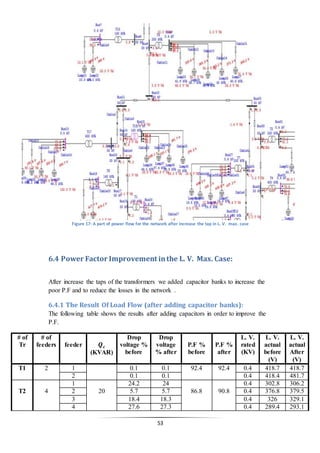

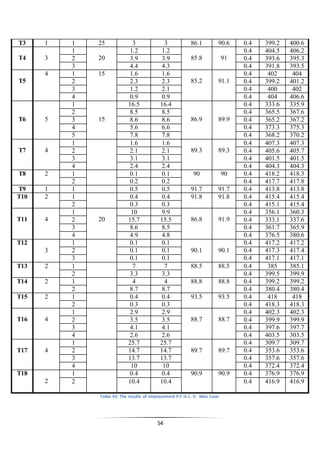

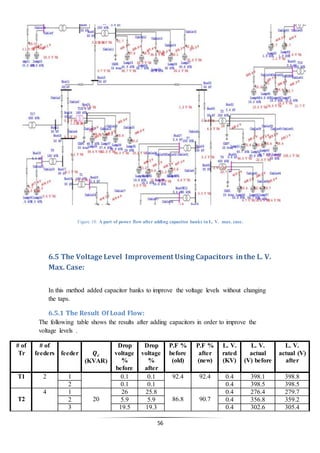

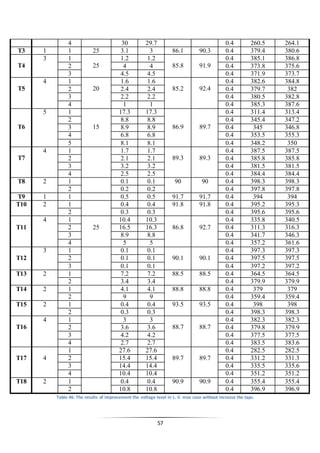

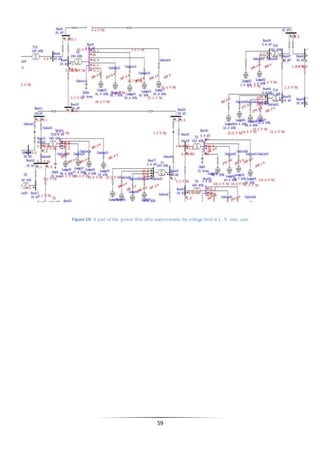

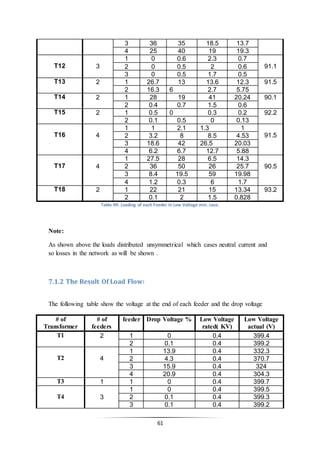

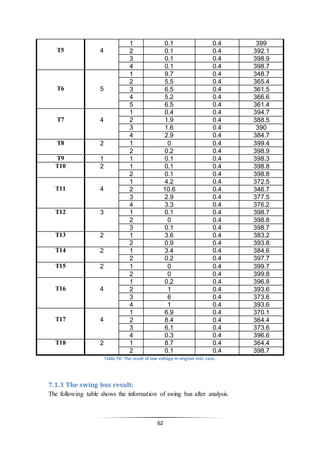

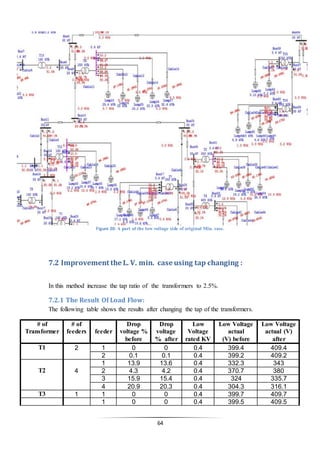

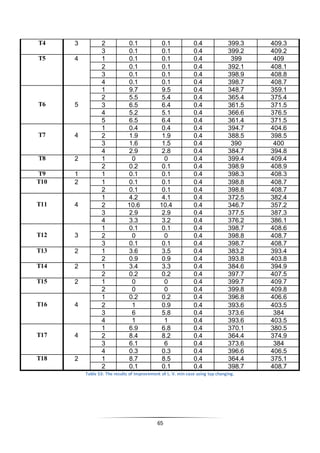

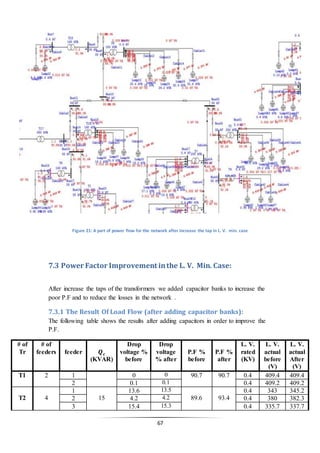

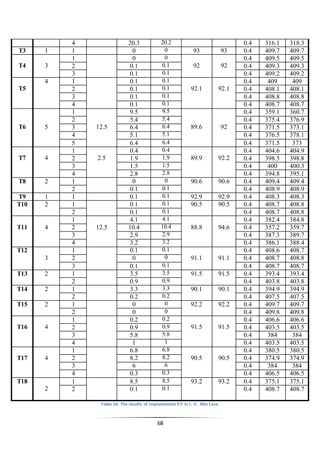

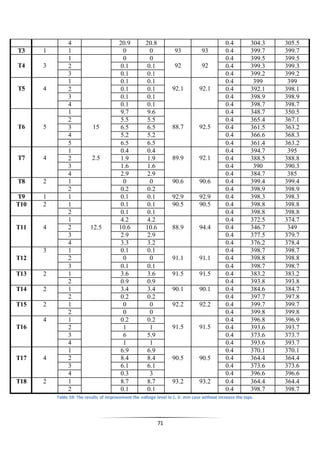

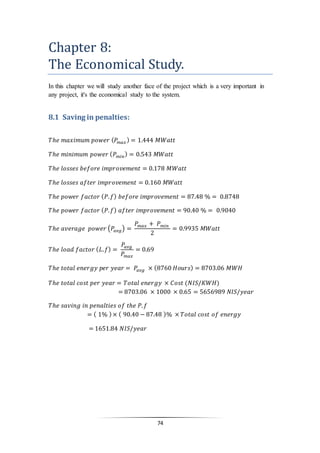

This document describes load flow analysis of the Aqraba power network in Jordan. It analyzes the network under maximum and minimum load cases. For each case, it examines the original scenario and various improvement scenarios including increasing swing bus voltage, adjusting transformer taps, improving power factor using capacitors, and reducing losses. Load flow results are presented including transformer loading, voltage profiles, generation requirements, and power losses. The document also analyzes low voltage sections of the network for both maximum and minimum load cases.