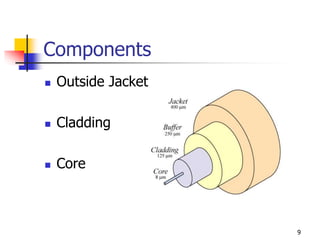

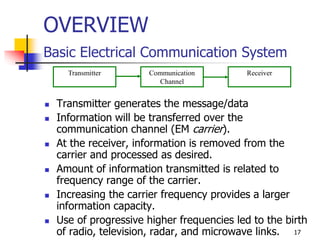

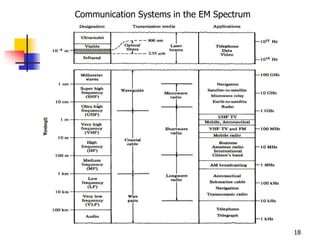

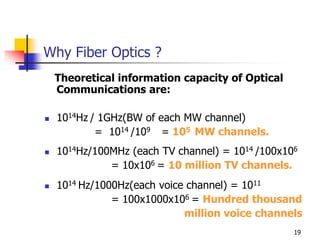

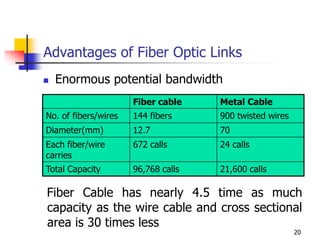

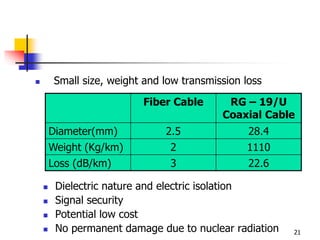

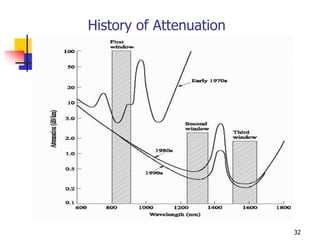

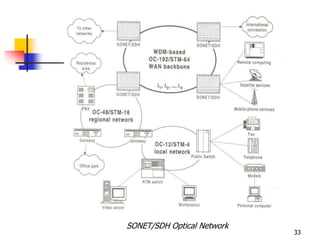

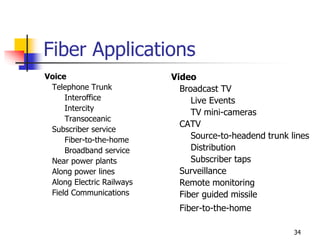

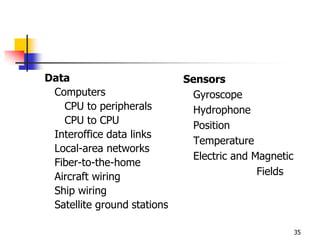

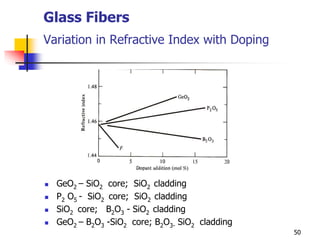

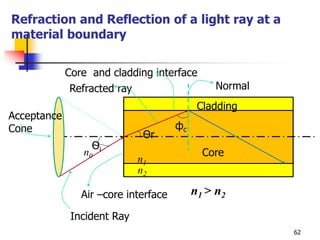

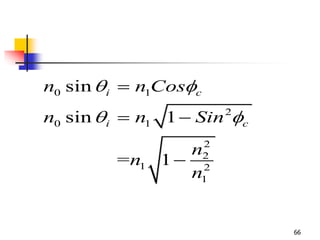

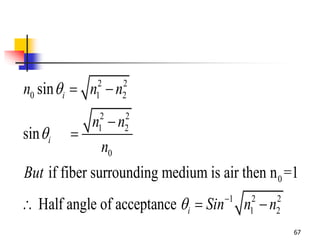

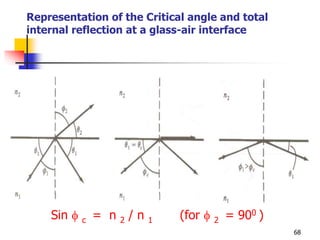

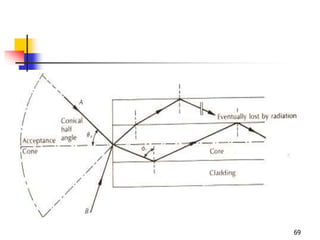

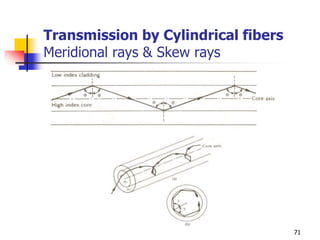

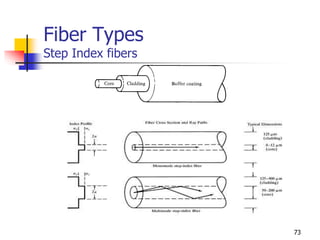

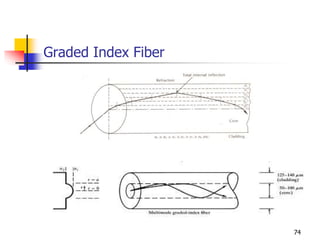

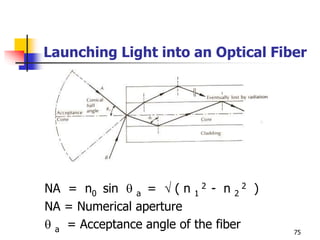

Optical fibers transmit large amounts of information using light. They were first demonstrated in 1961 but high losses prevented communication uses until the 1970s. Researchers found ways to super purify glass fibers, reducing losses. AT&T installed the first fiber optic cables in major cities in 1980. Fibers transmit voice, television, and data using digital signals and WDM. They have enormous bandwidth potential and advantages over metal cables. Fibers guide light through total internal reflection using cores and claddings with slightly different refractive indices.