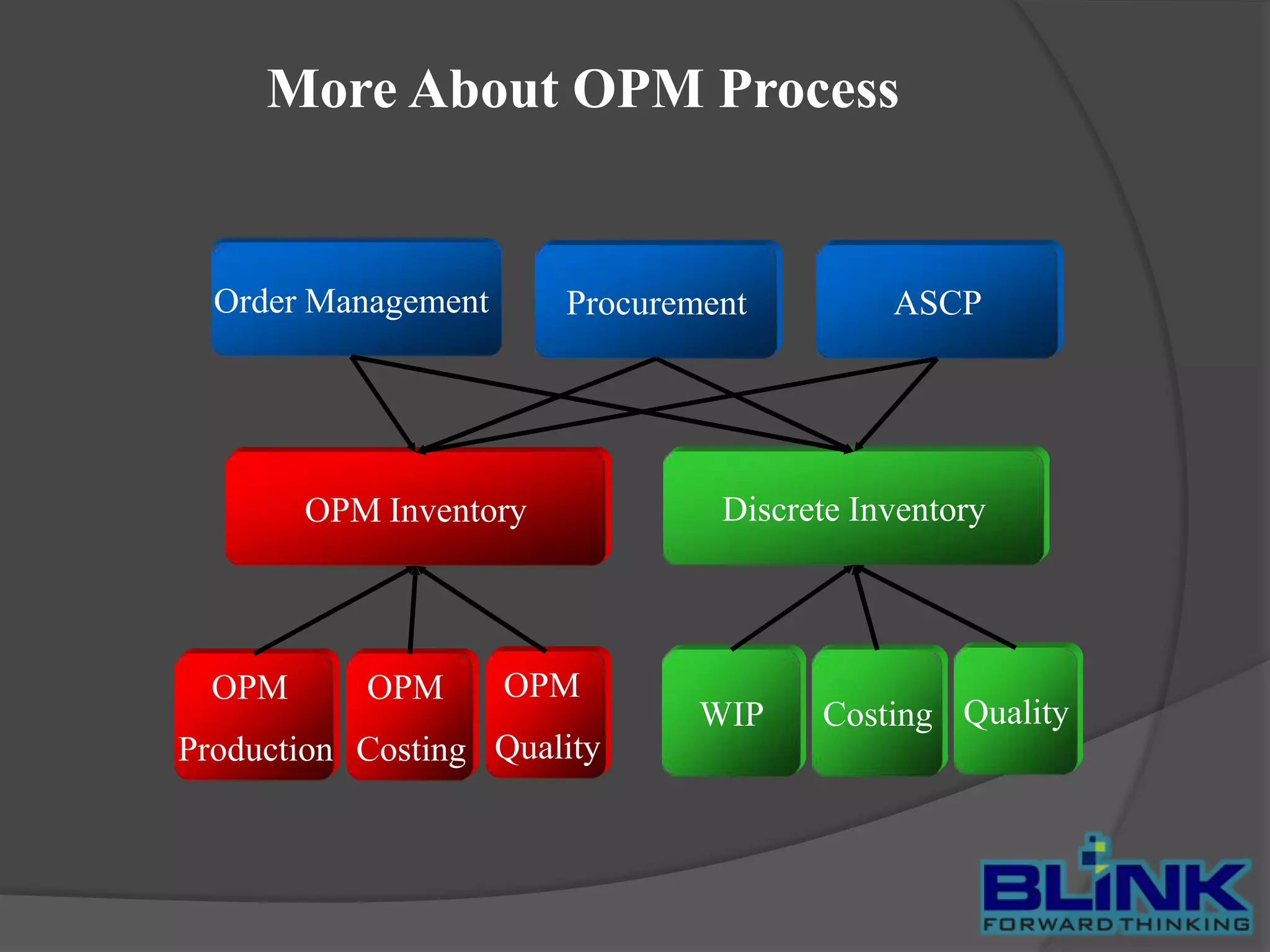

The document discusses Oracle Process Manufacturing (OPM) and its benefits for businesses, highlighting its importance in synchronizing manufacturing processes with operations. OPM is specifically designed for industries producing similar products in bulk or customizing products as needed, addressing significant challenges in inventory control and manufacturing visibility. Blink's OPM solution enhances operational efficiency by allowing real-time data collection through handheld devices, improving control and visibility in manufacturing activities.