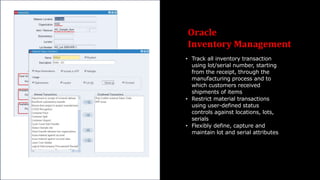

This document provides an overview of how Oracle EBS can optimize manufacturing processes. It discusses challenges manufacturers face around inefficient processes and lack of visibility. It then outlines the key benefits and features of Oracle EBS for manufacturing, including inventory management, production planning, quality control and cost management. The document concludes that Oracle EBS is a powerful solution that enables efficiency, control and competitive advantage for manufacturers.