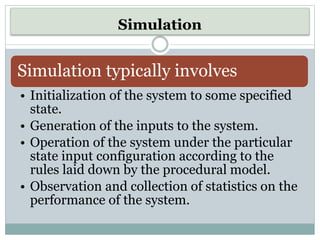

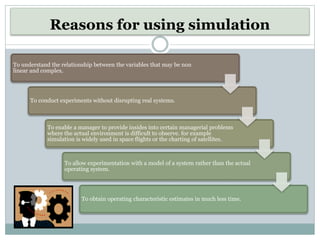

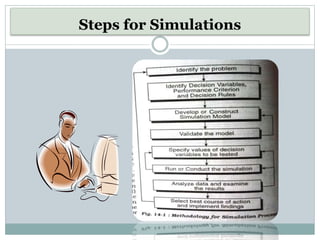

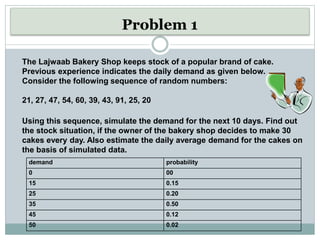

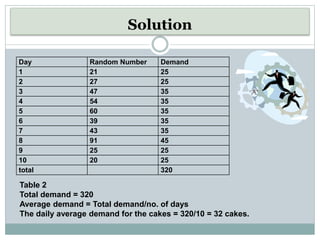

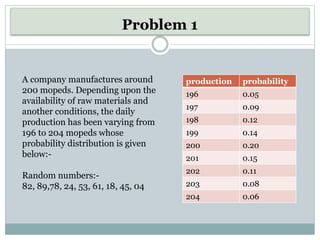

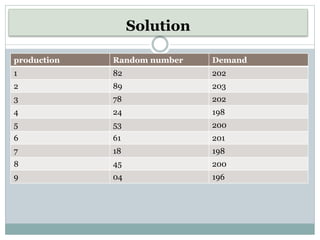

This document discusses simulation as a technique used in operations research to analyze the behavior of systems. It provides examples of how simulation works by initializing a system, generating inputs, observing outputs, and collecting statistics. Some key uses of simulation mentioned include testing policy decisions, conducting experiments without disrupting real systems, and obtaining operating characteristics estimates faster than working with actual systems. The document also outlines some advantages and limitations of the simulation approach. It includes two examples demonstrating how to simulate daily demand for a bakery and daily production for a moped manufacturer using random numbers.