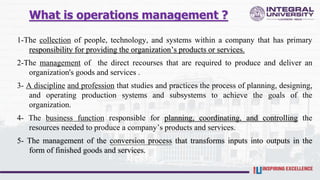

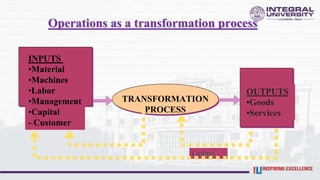

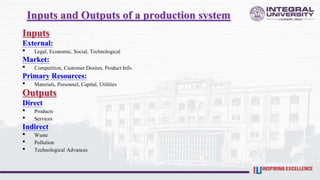

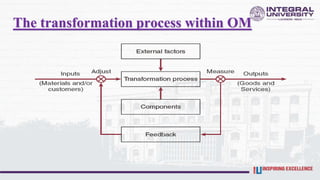

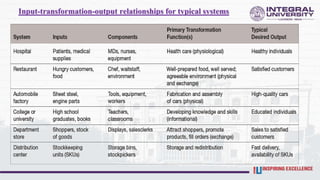

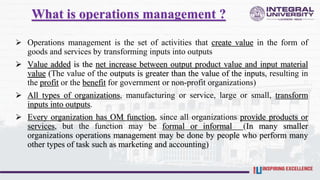

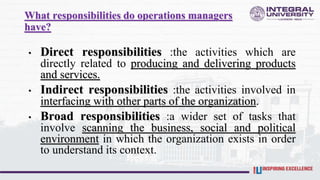

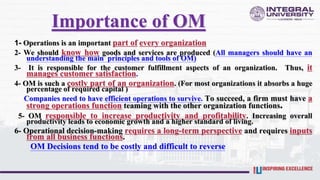

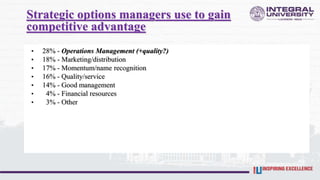

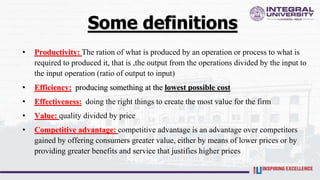

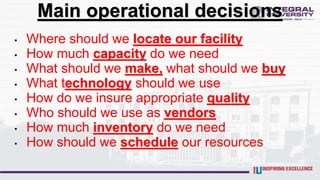

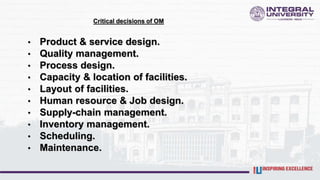

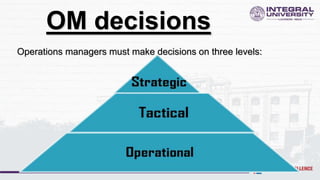

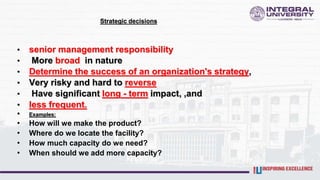

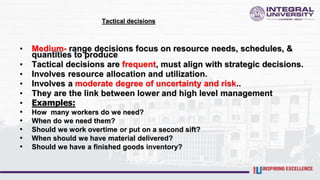

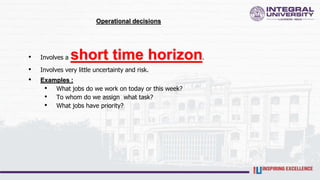

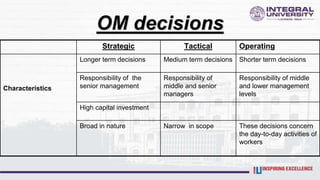

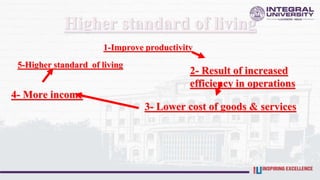

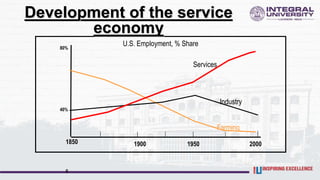

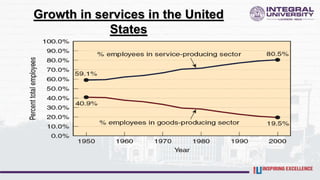

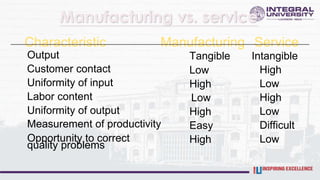

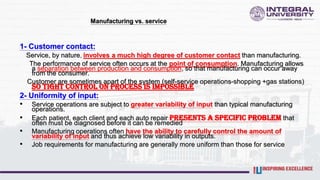

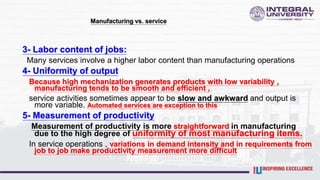

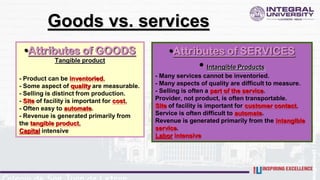

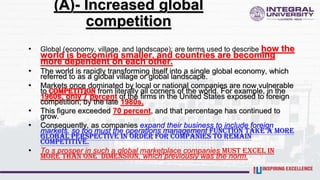

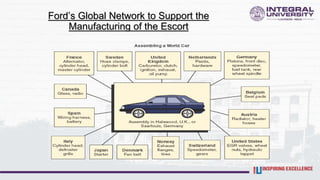

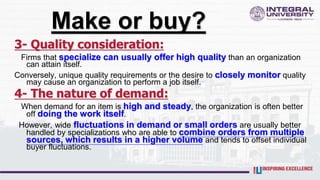

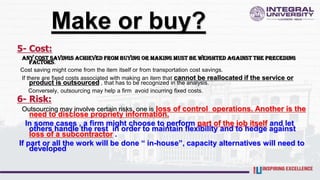

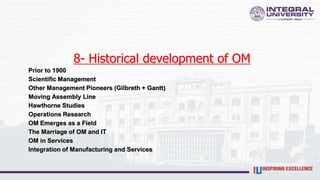

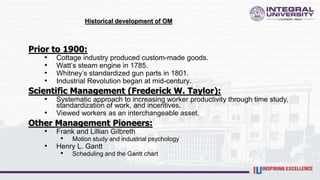

The document provides an overview of Operations Management (OM), detailing its definition, importance, roles, and contributions to society and the economy. It discusses the responsibilities of operations managers, the significance of OM in both service and manufacturing contexts, and the evolving nature of OM in response to global competition and technological advancements. Key concepts include decision-making processes in OM, the distinctions between operations and production management, and the impact of OM on productivity, customer satisfaction, and quality of goods and services.