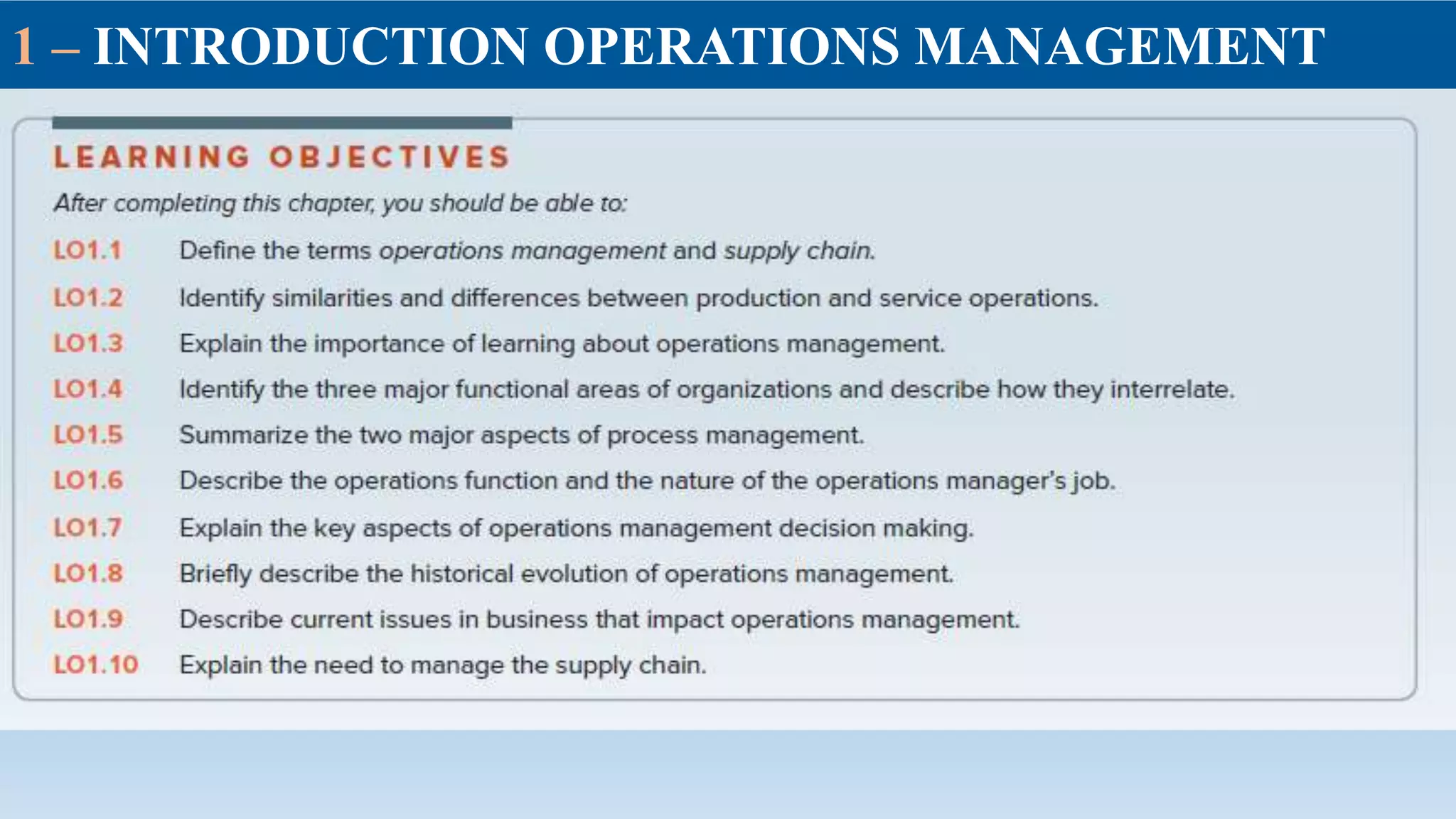

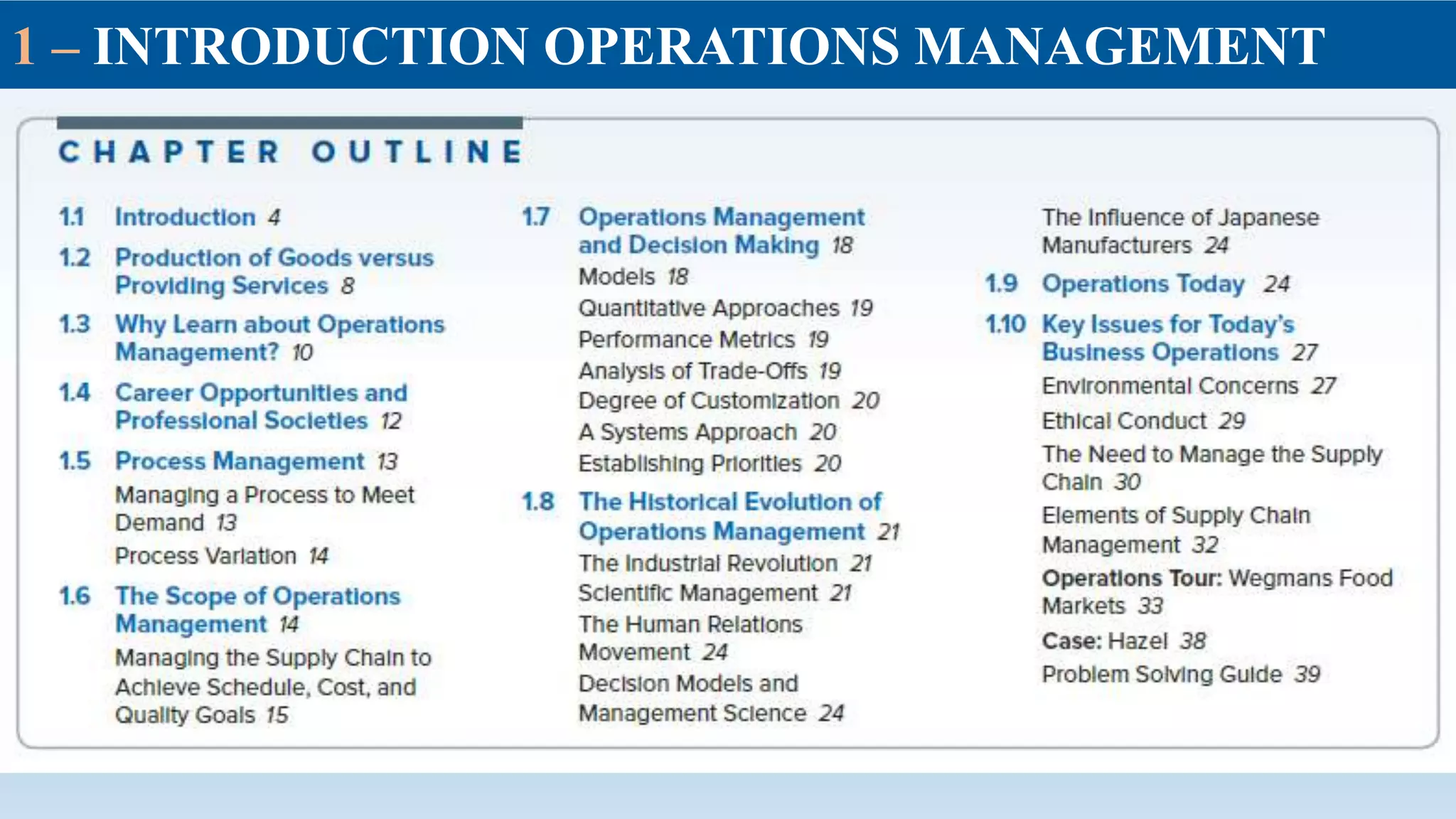

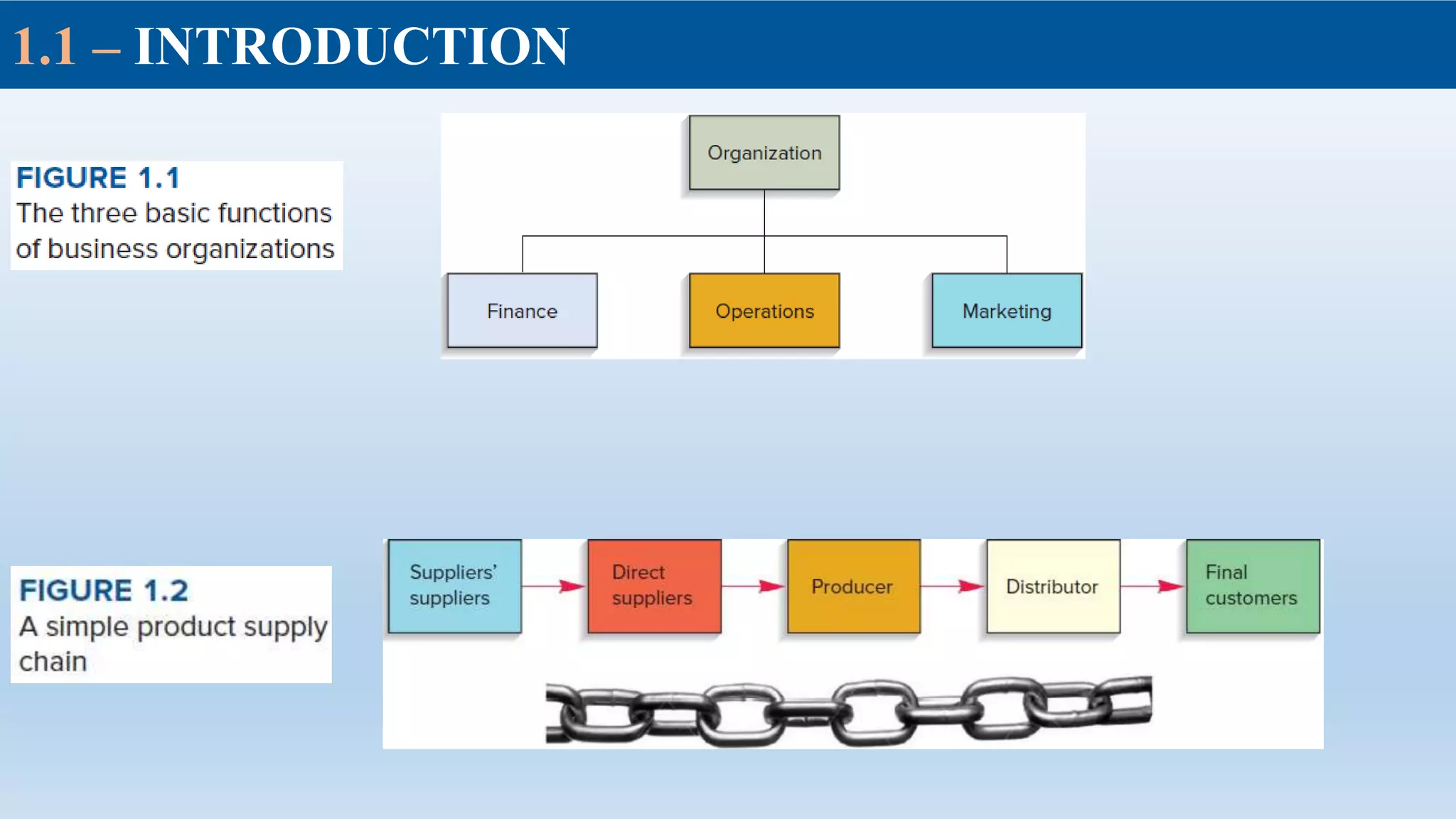

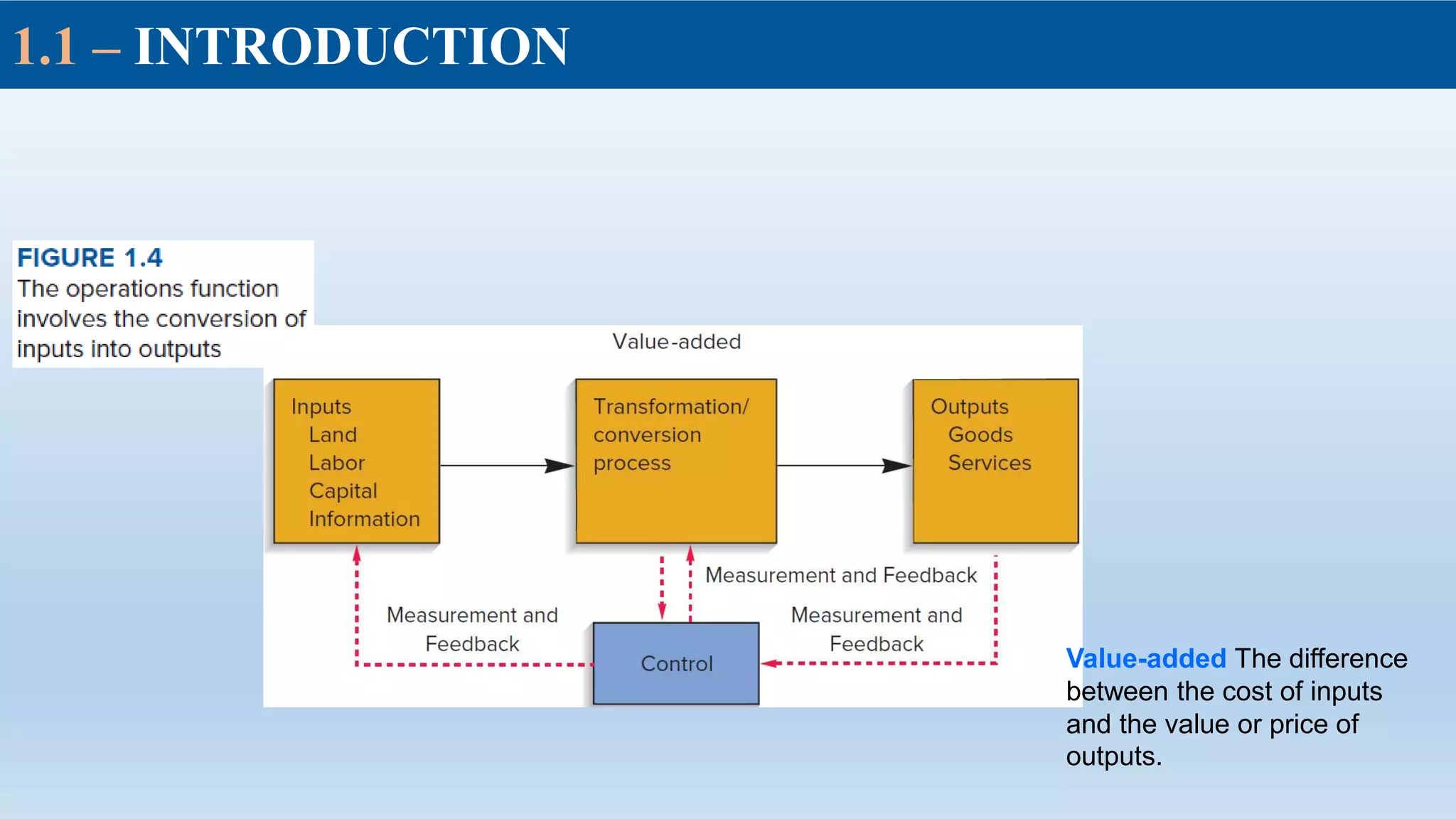

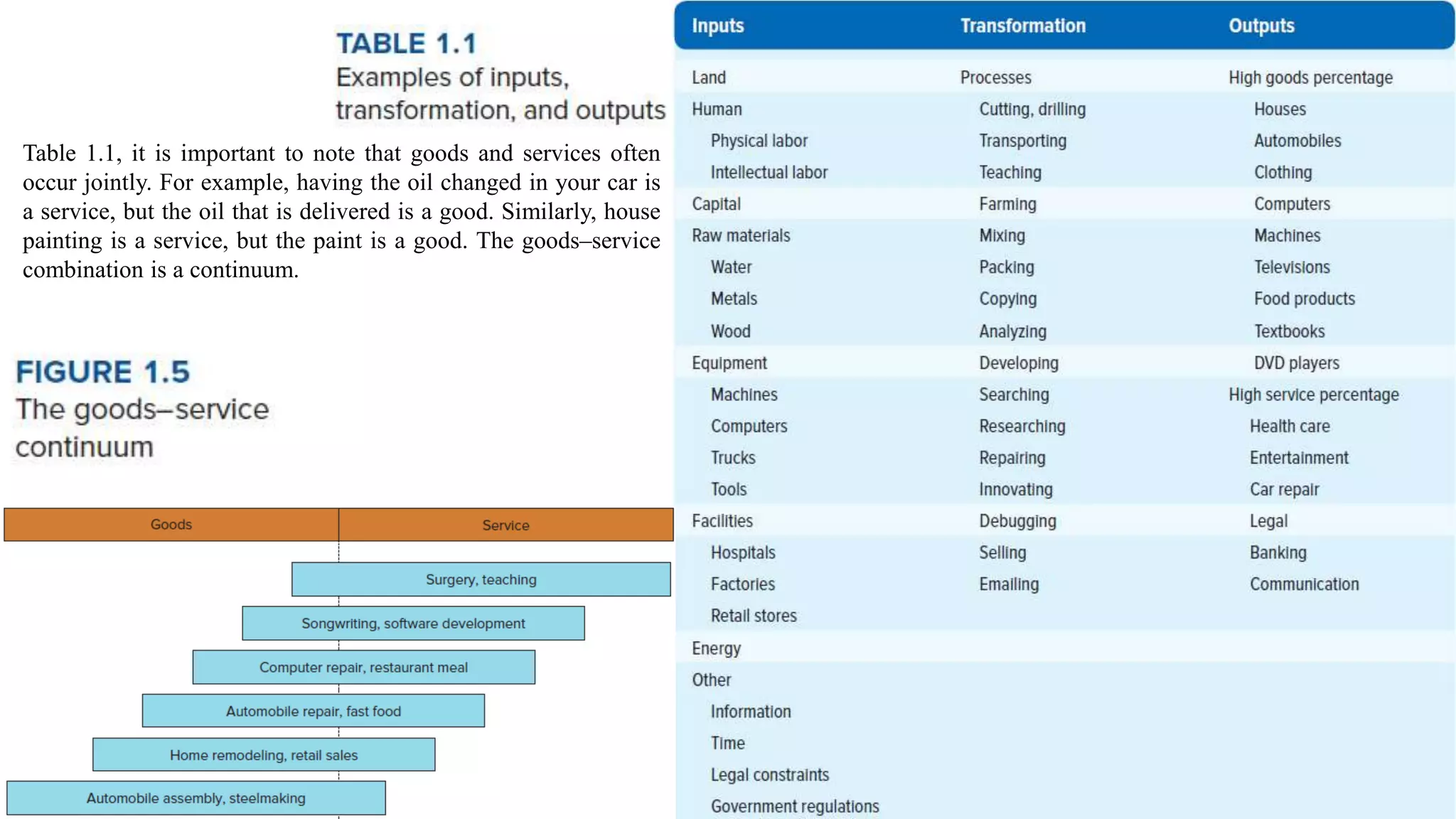

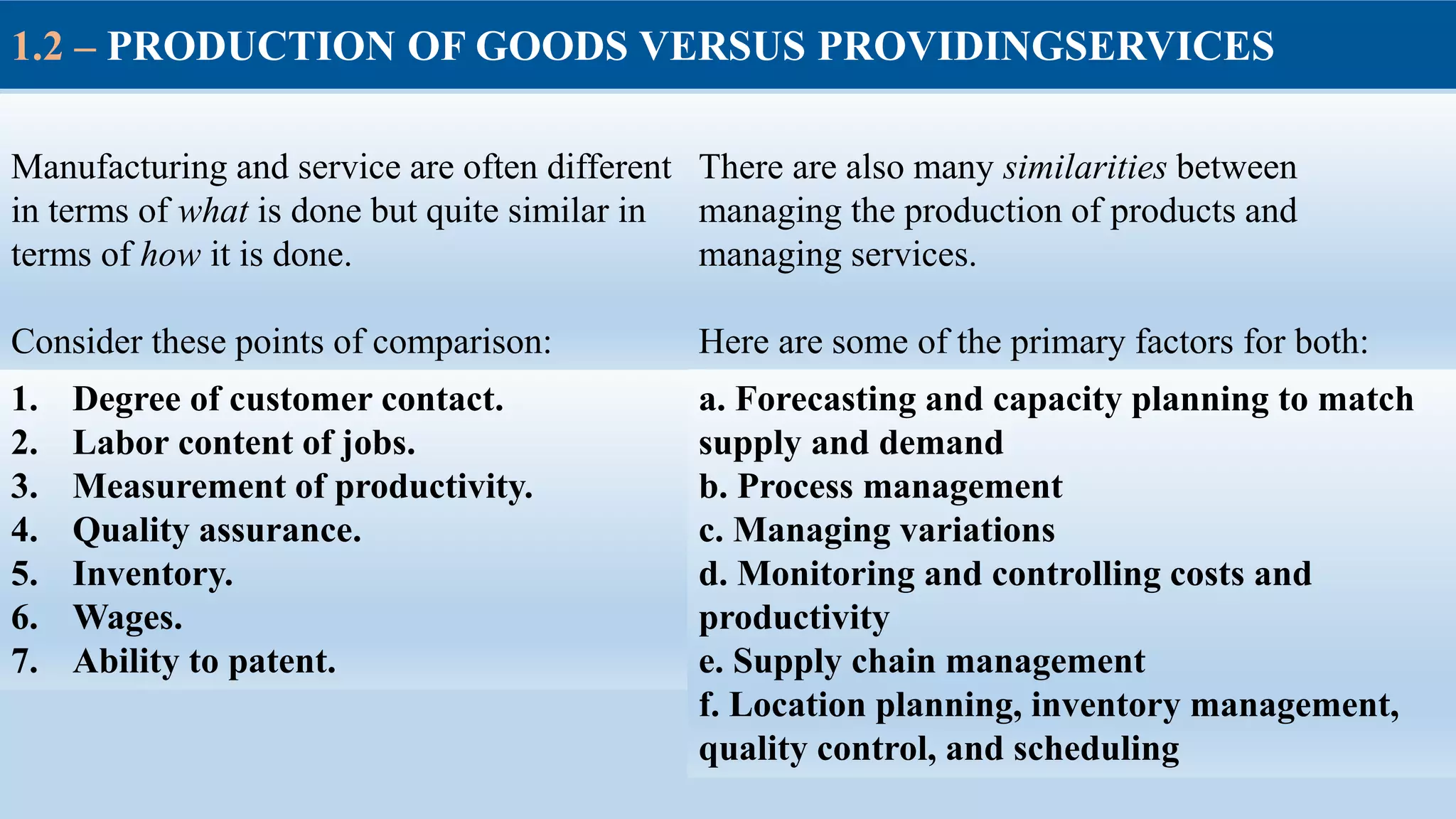

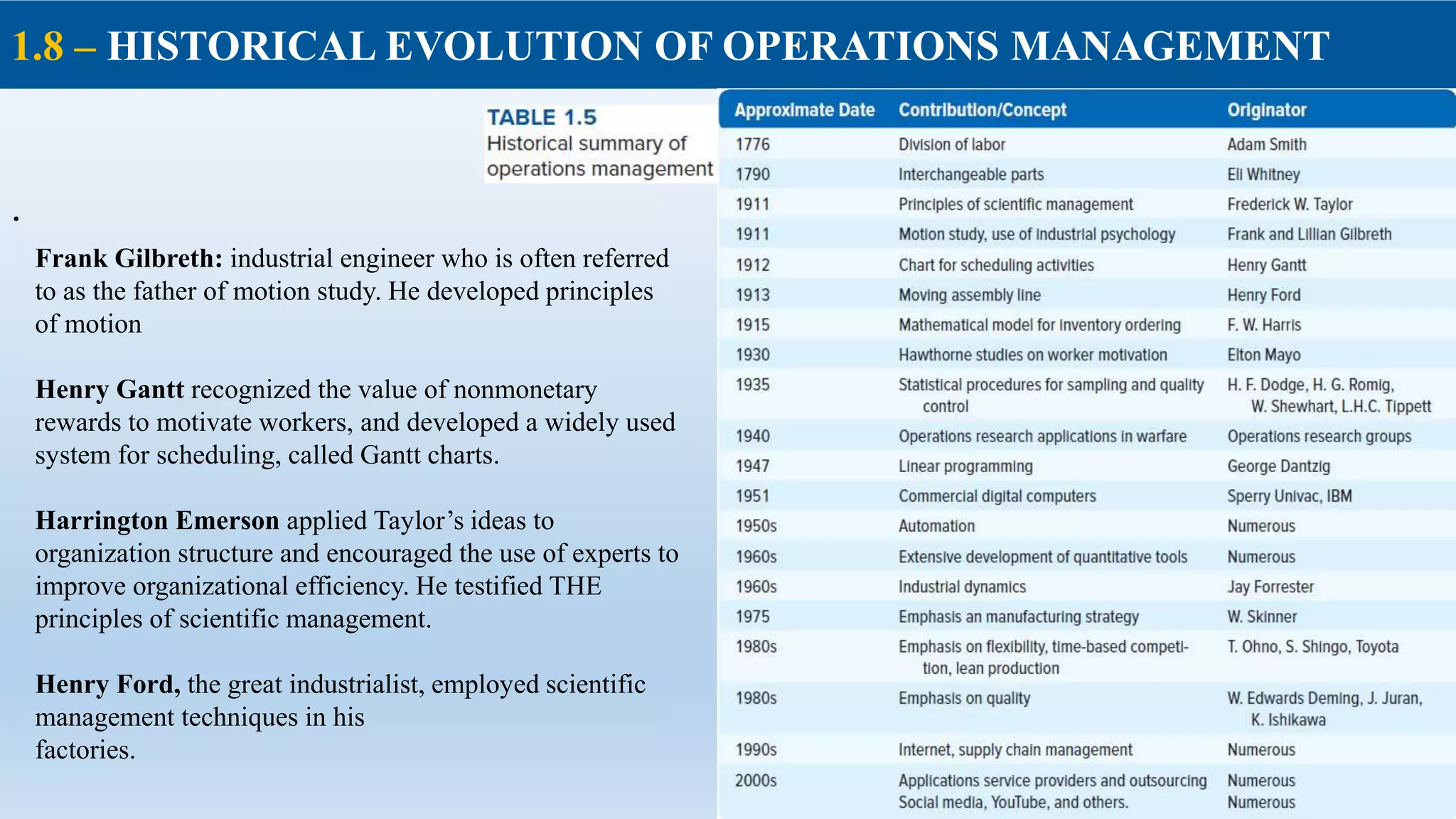

This document provides an introduction to operations management. It discusses the differences between manufacturing goods and providing services, and notes there are also many similarities in how they are managed. Key factors for managing both include forecasting, process management, managing variations, monitoring costs and productivity, and supply chain management. The document also outlines the scope and importance of operations management, how decision making is involved, some of the historical developments in the field, and key issues today like quality, risk management, and competing in a global economy.