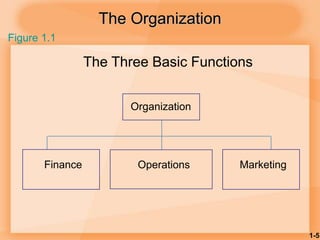

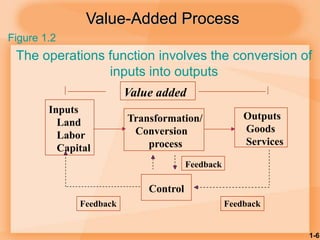

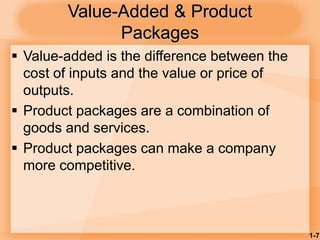

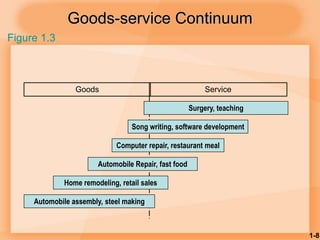

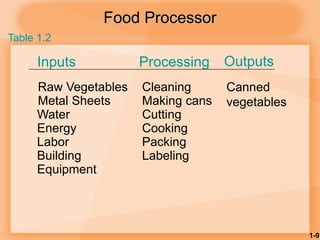

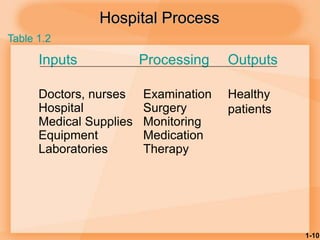

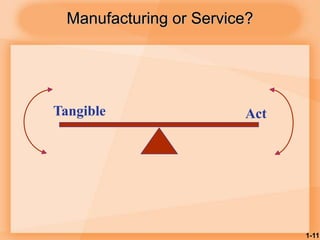

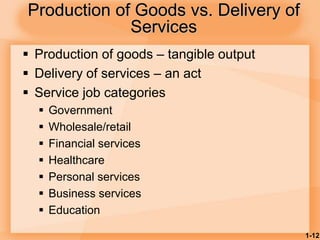

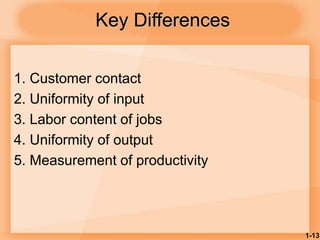

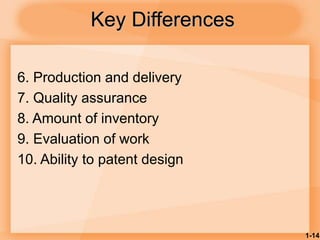

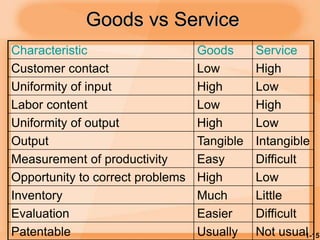

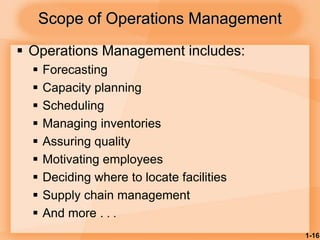

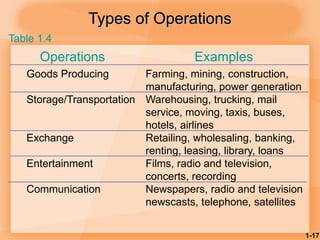

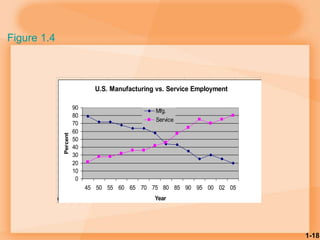

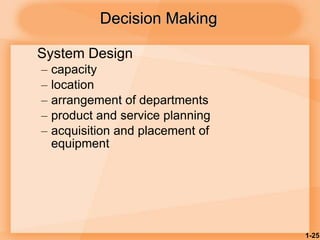

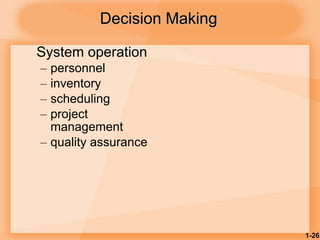

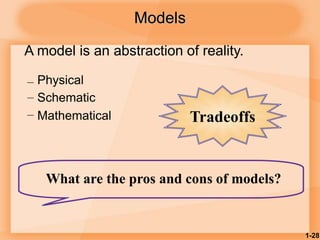

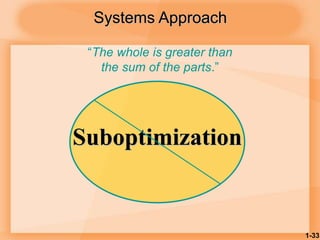

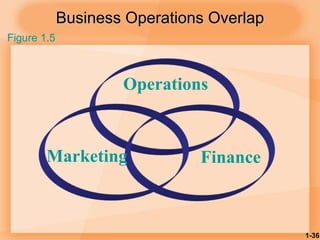

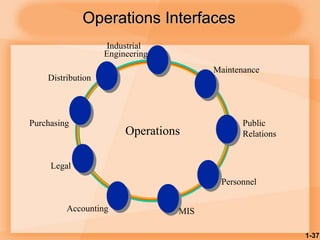

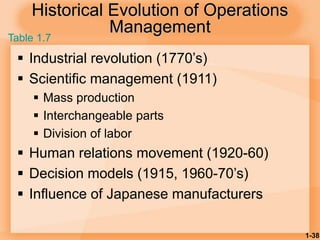

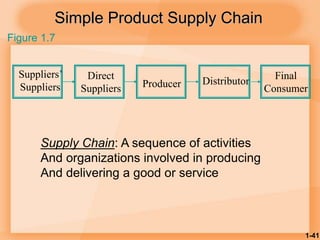

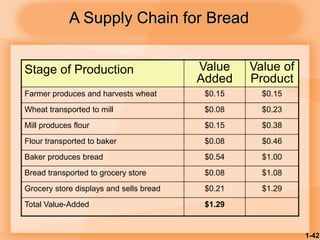

This document serves as an introduction to operations management, covering its definition, the interrelationship of key functional areas, and the distinctions between service and manufacturing operations. It emphasizes the role of operations management in enhancing competitive advantage and outlines key aspects such as decision making, service challenges, and historical evolution. Current trends affecting operations management, including technology and globalization, are also addressed along with the importance of value-added processes.