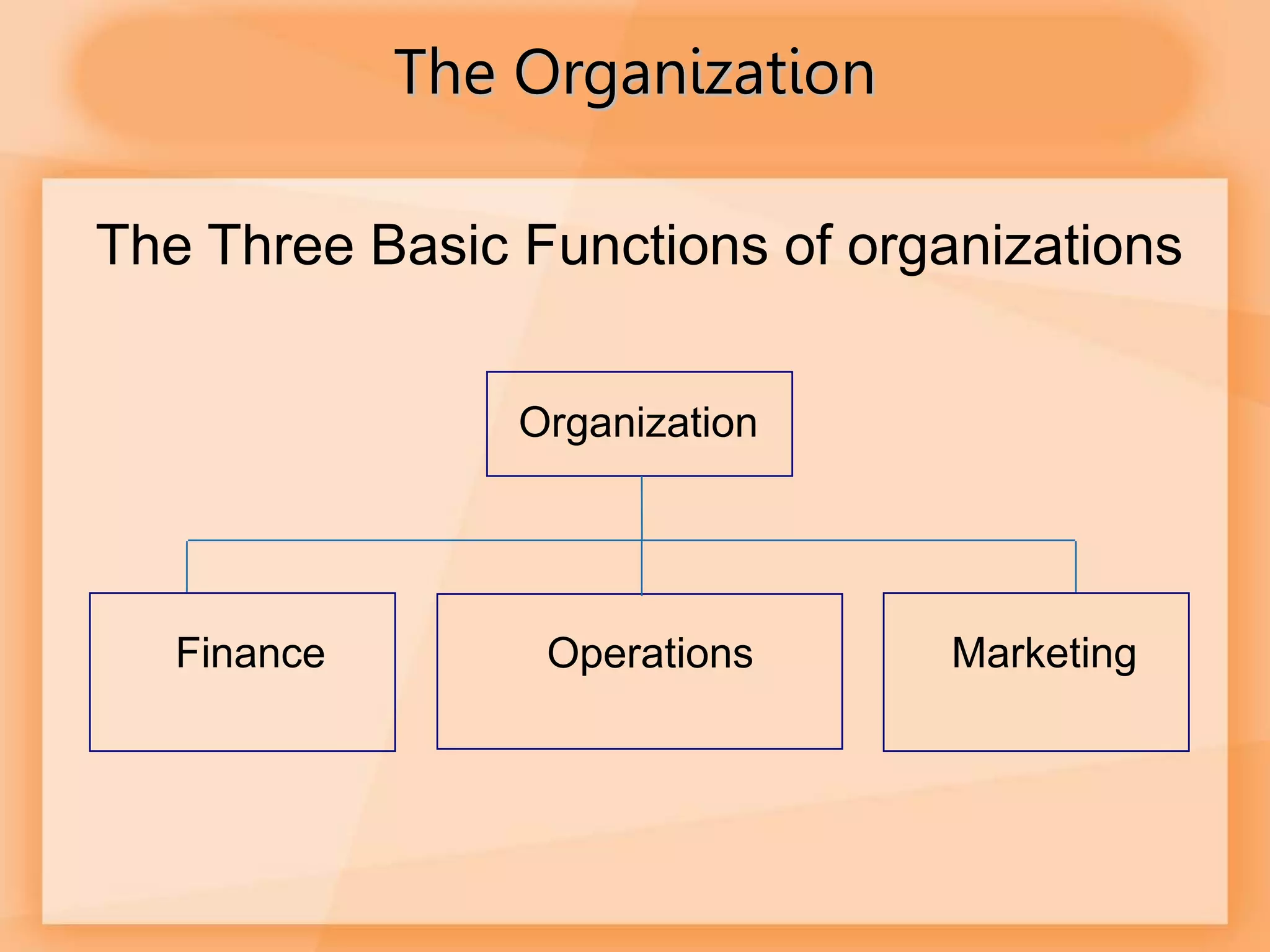

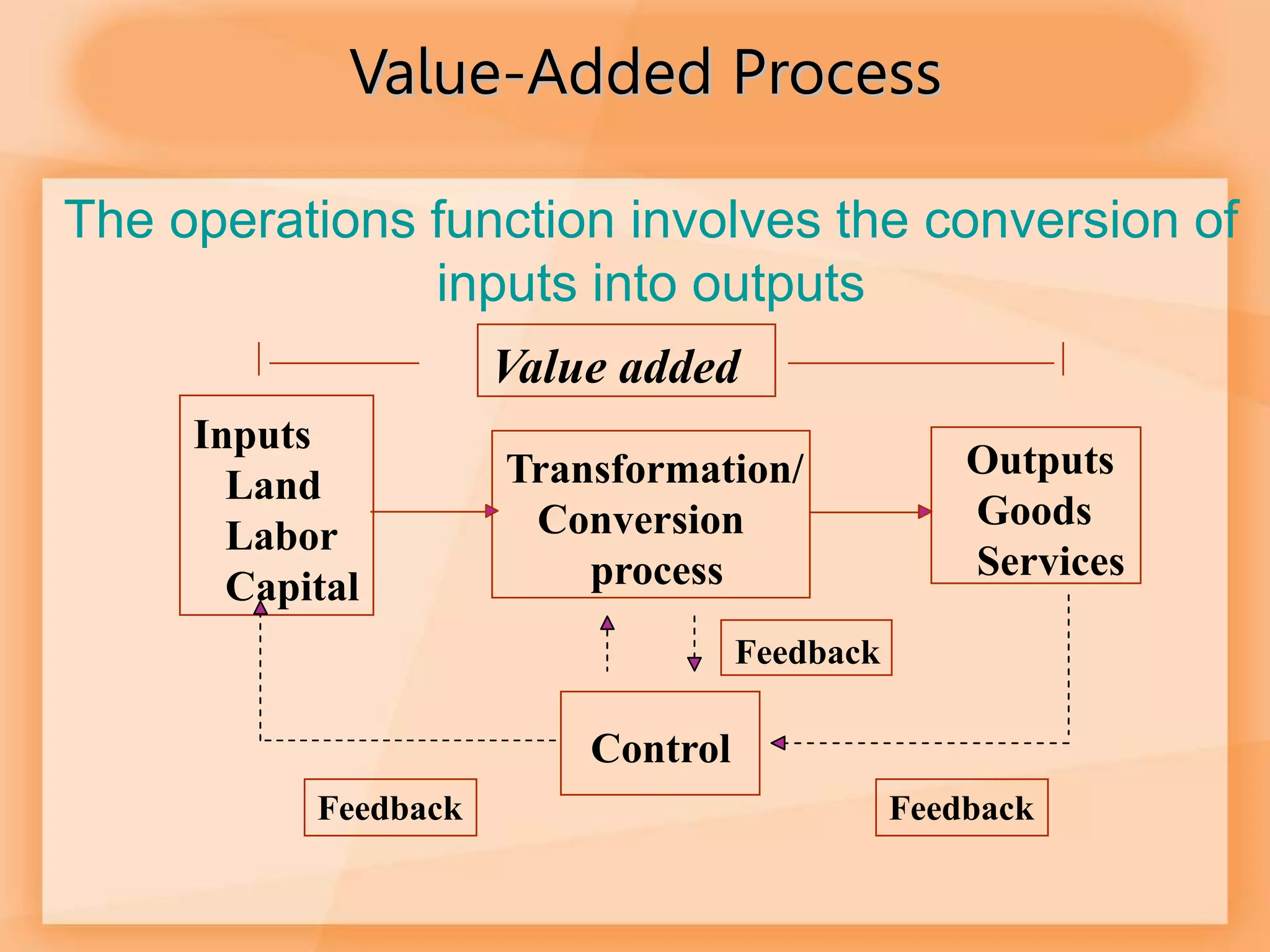

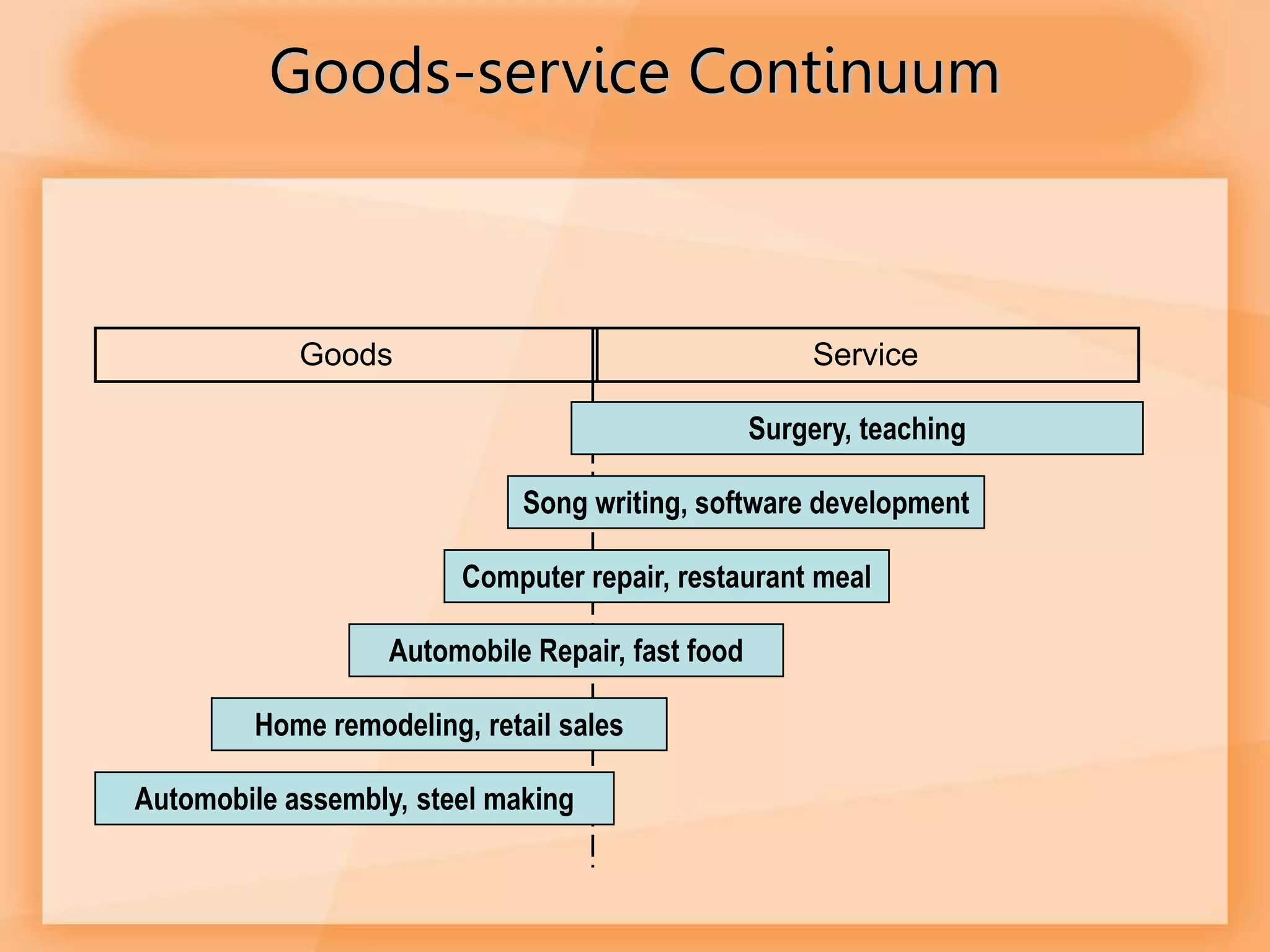

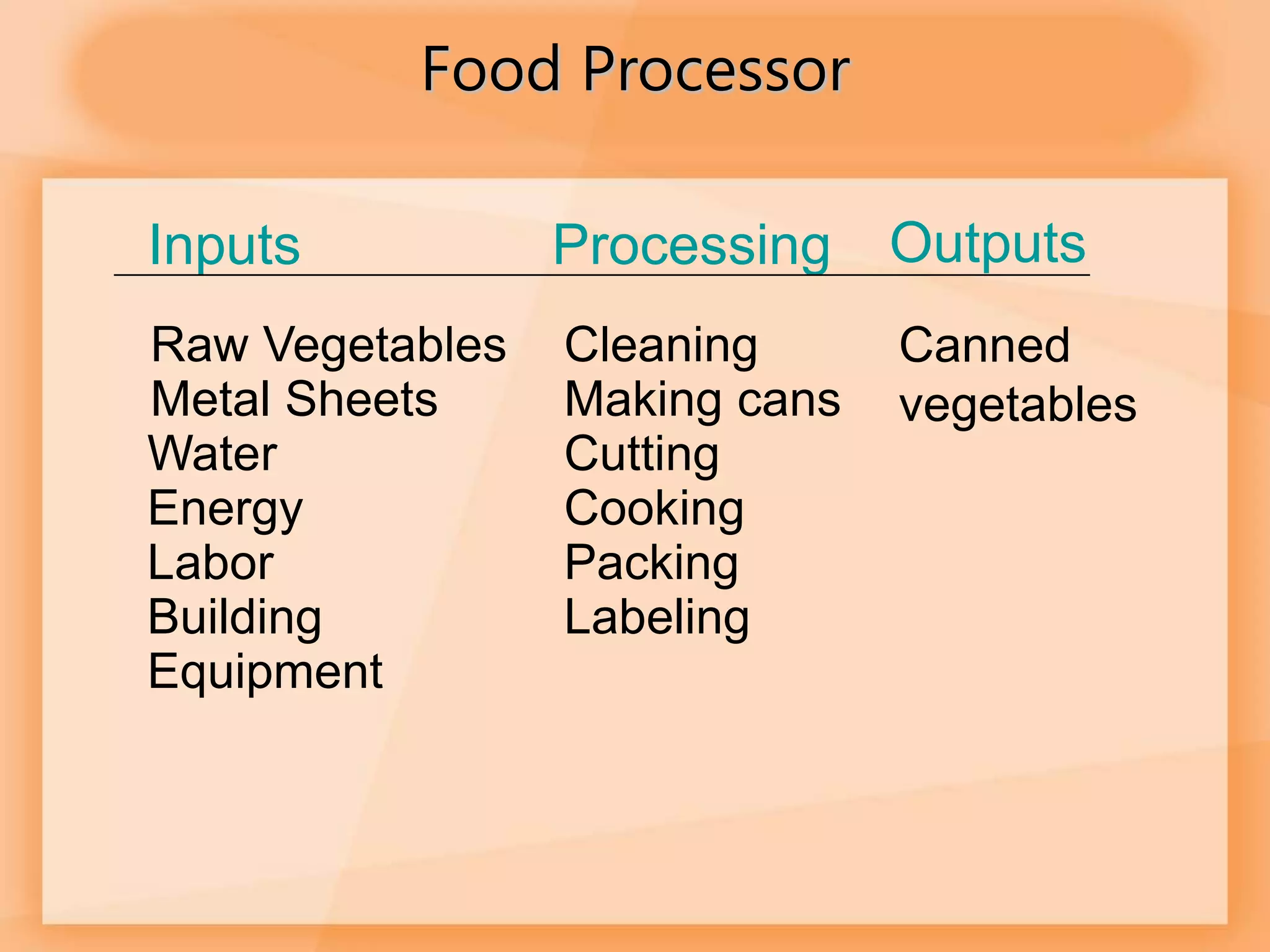

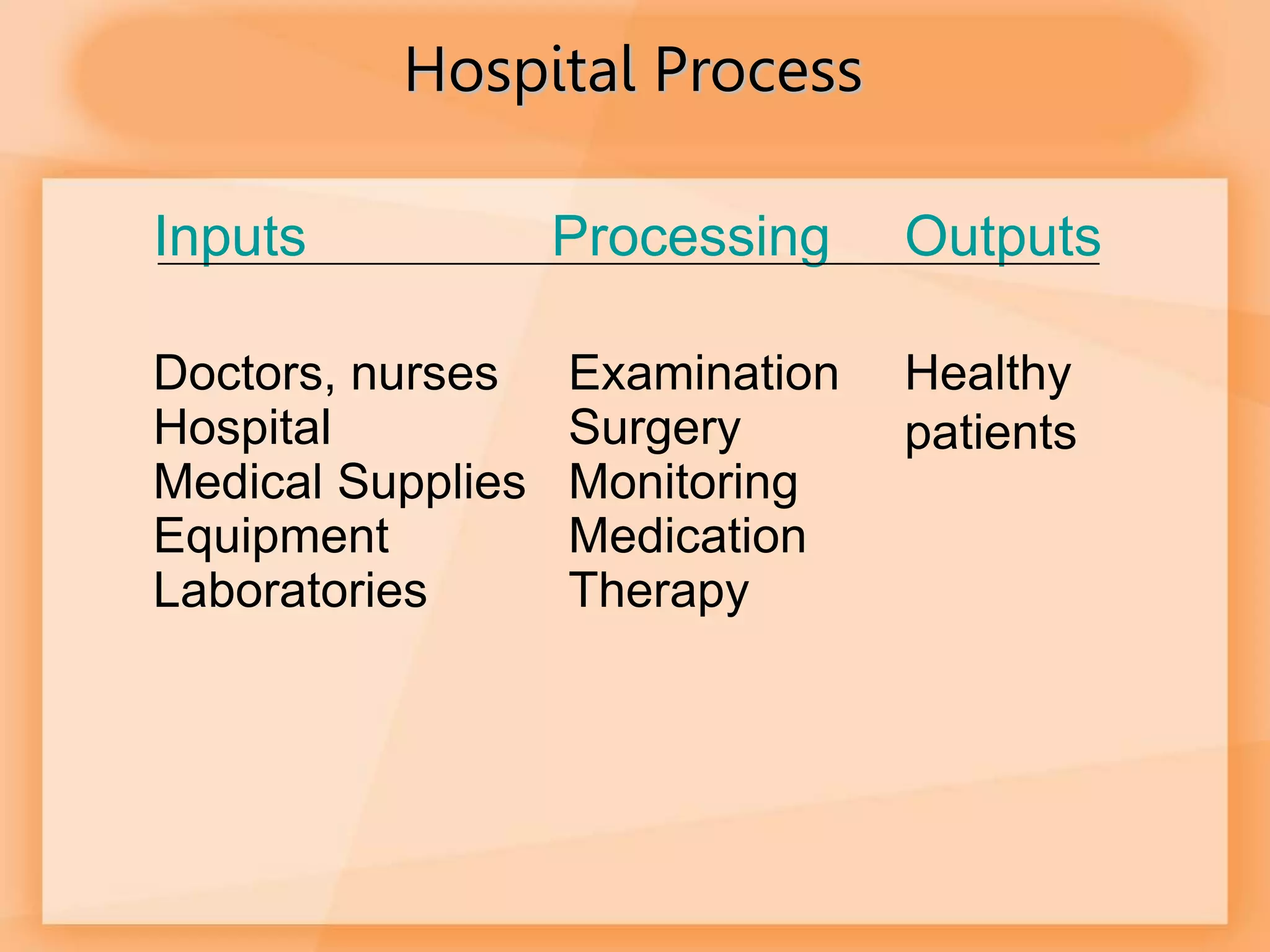

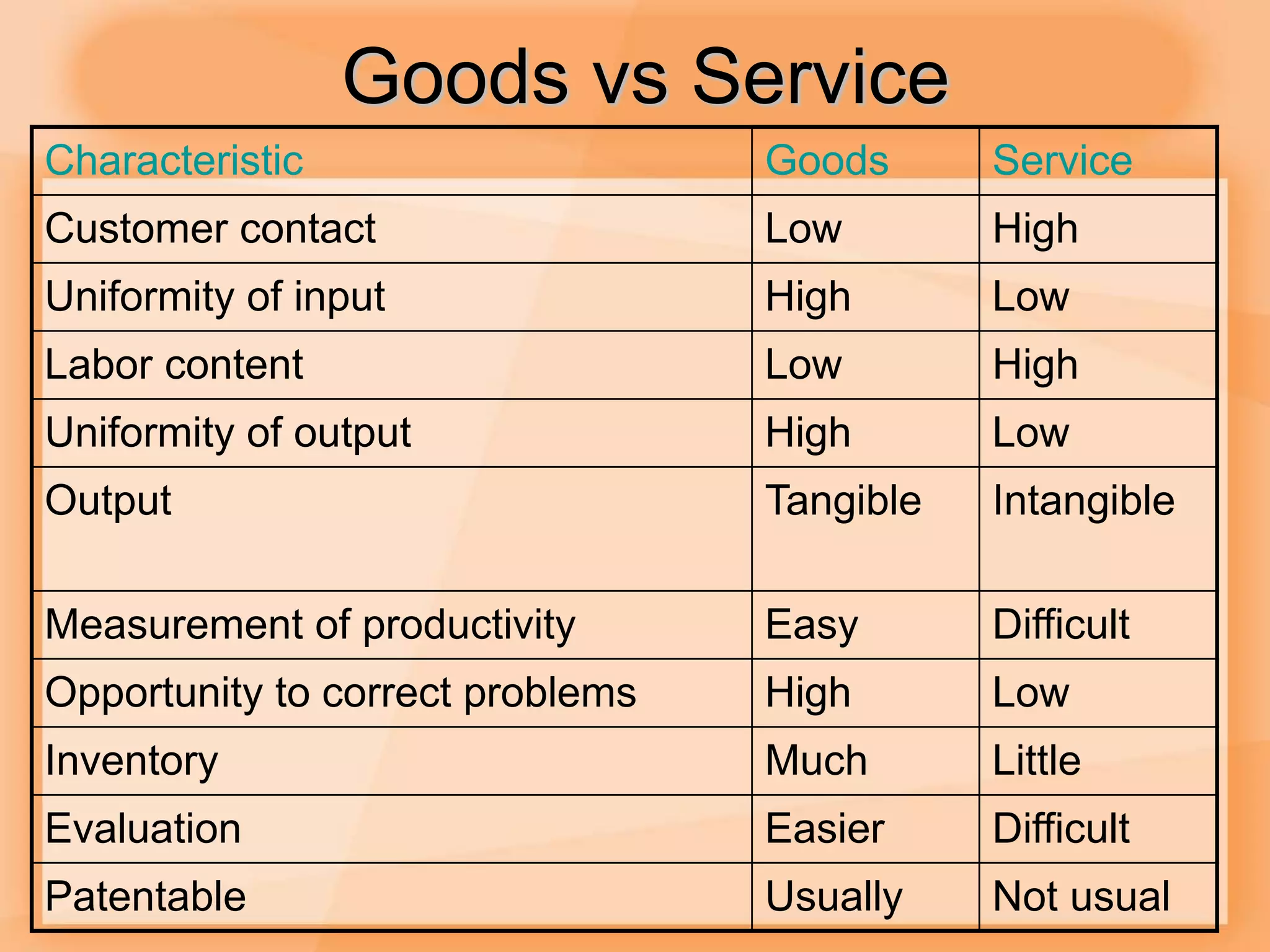

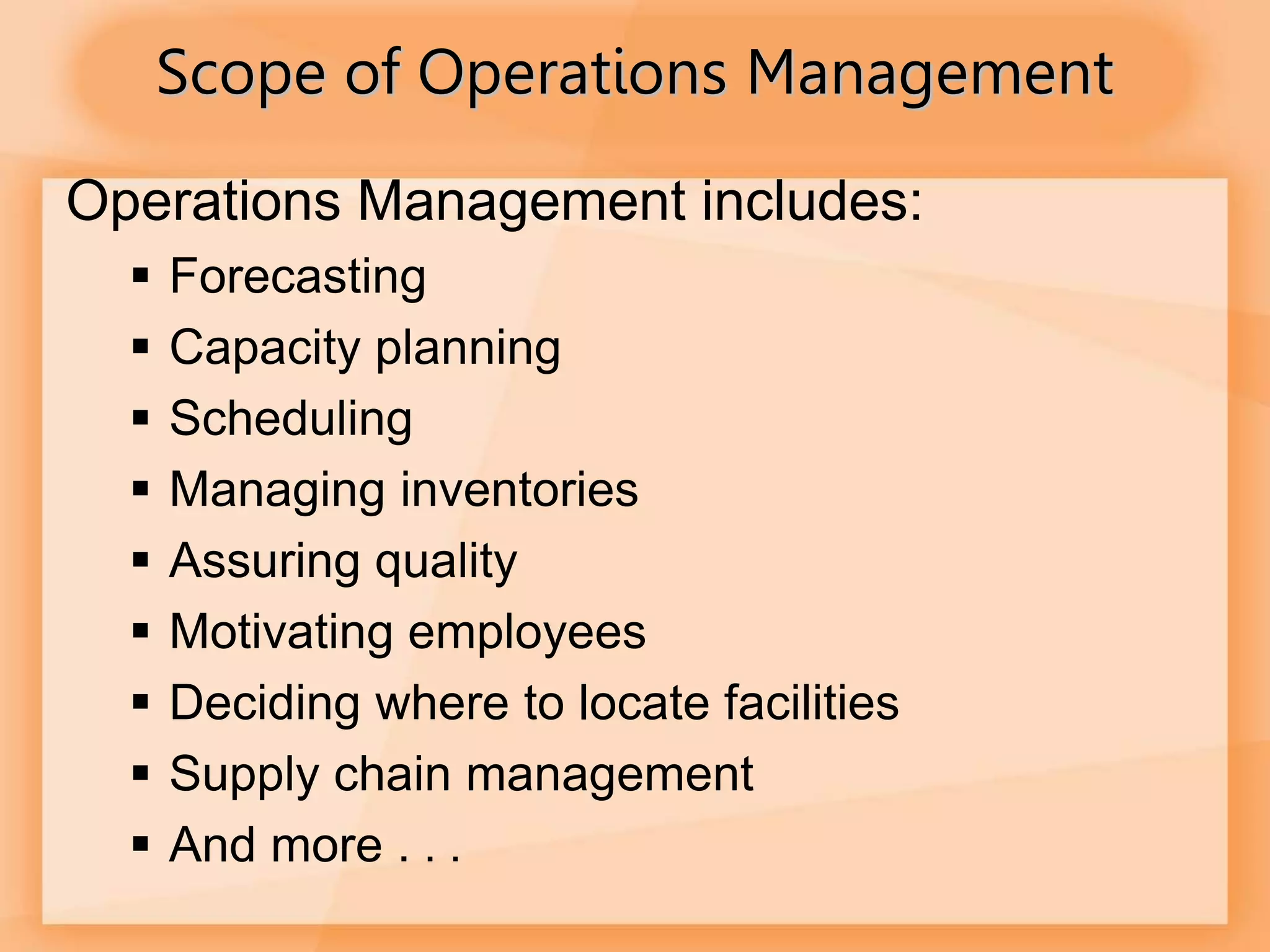

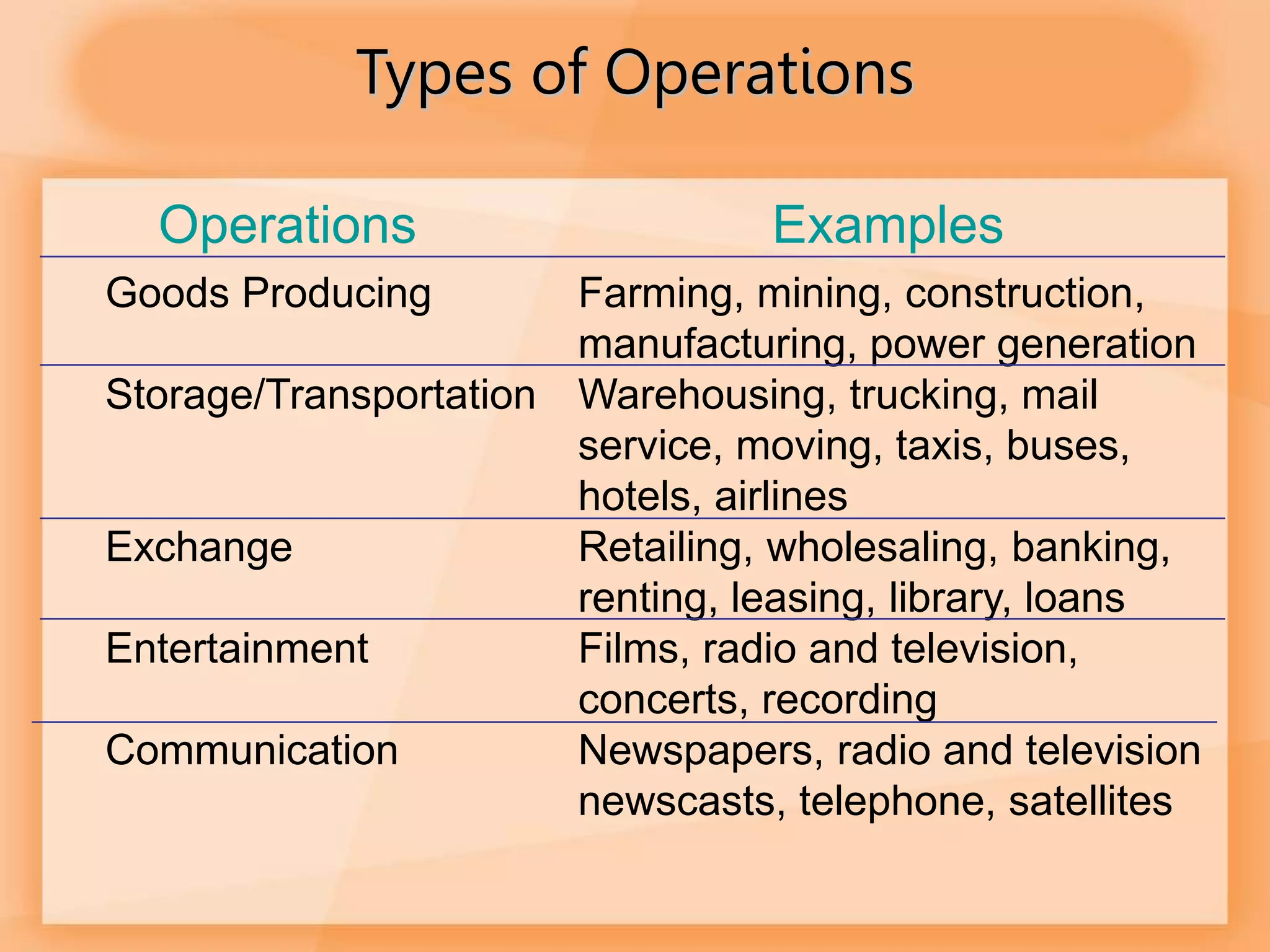

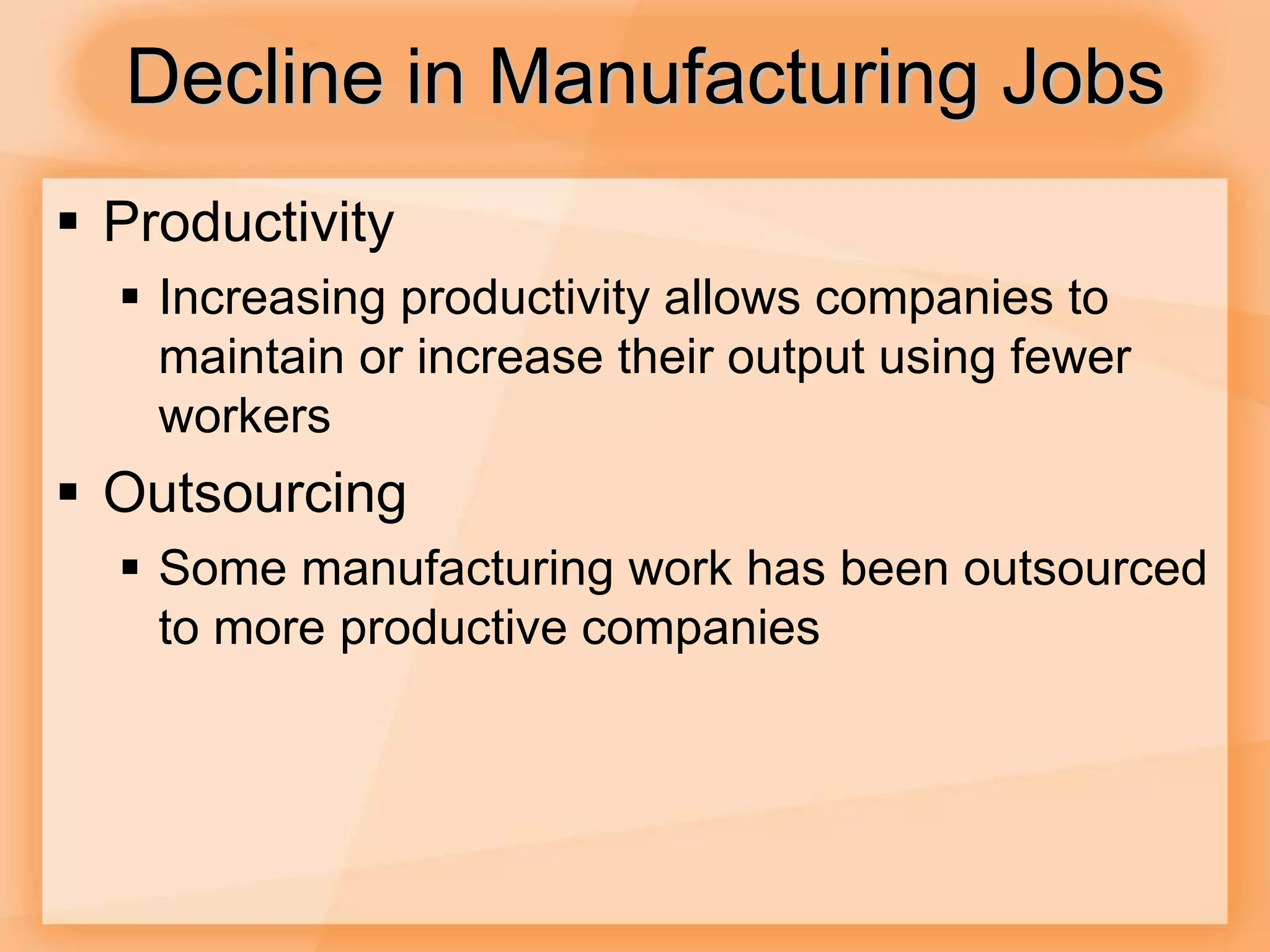

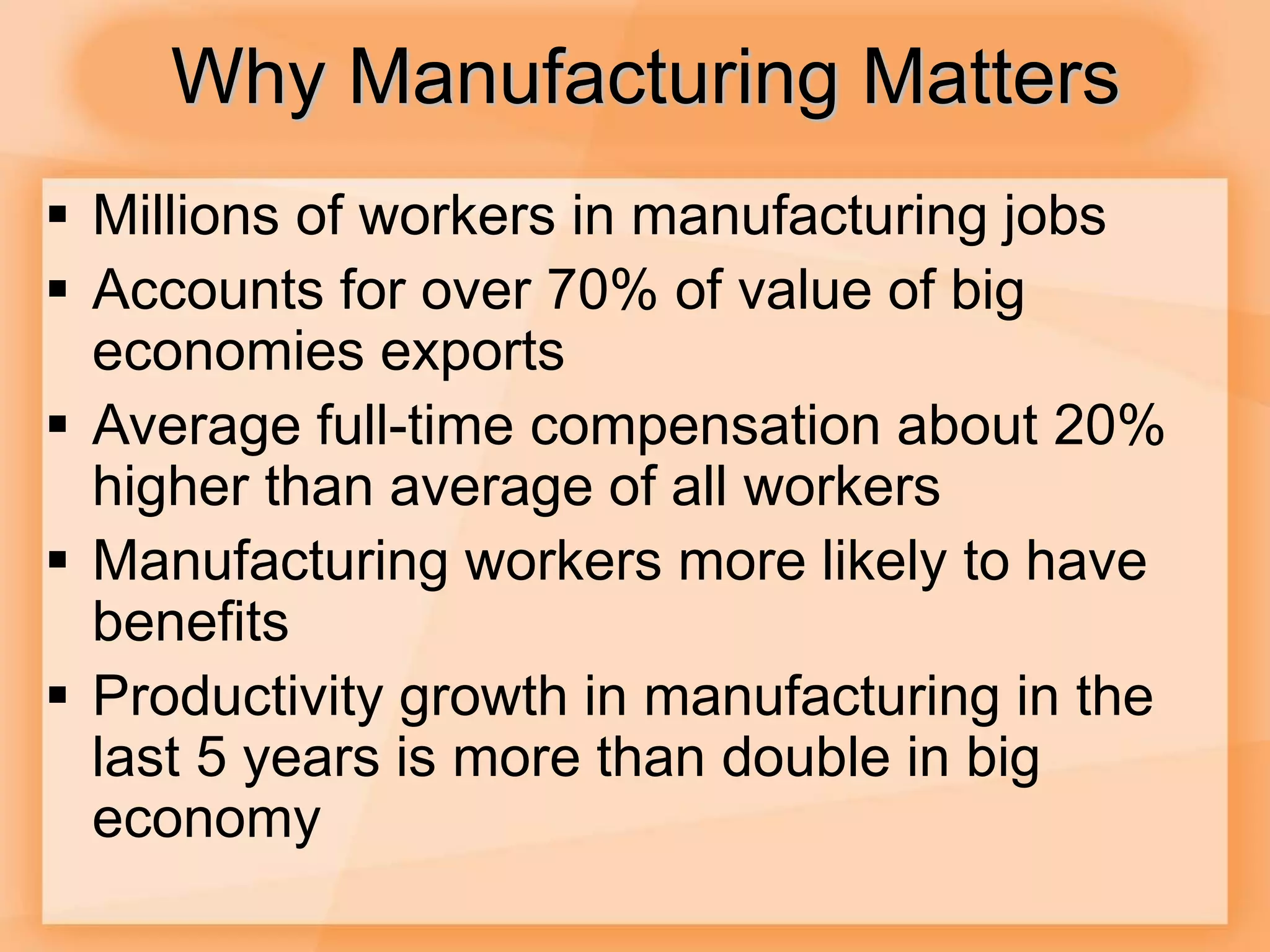

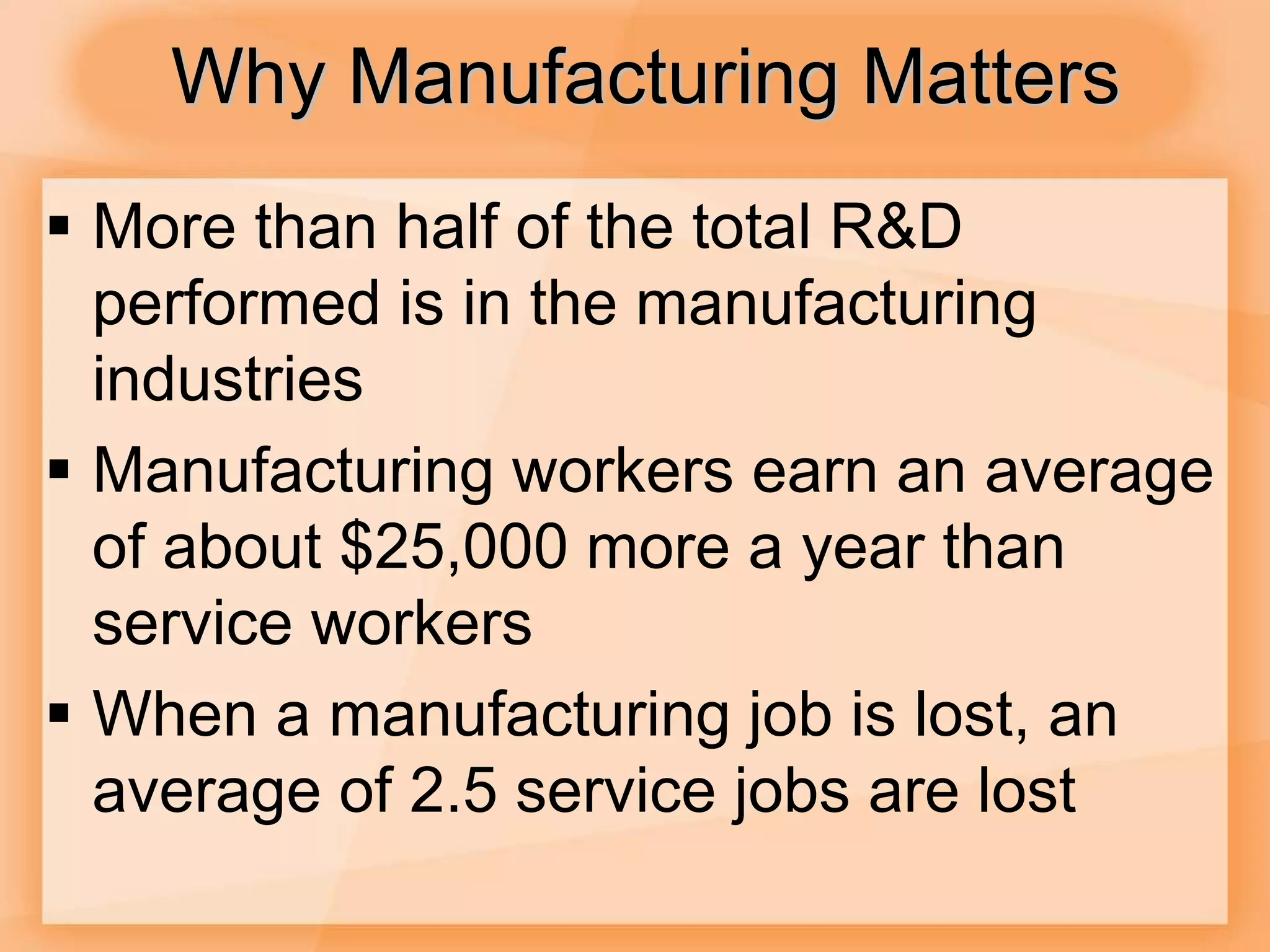

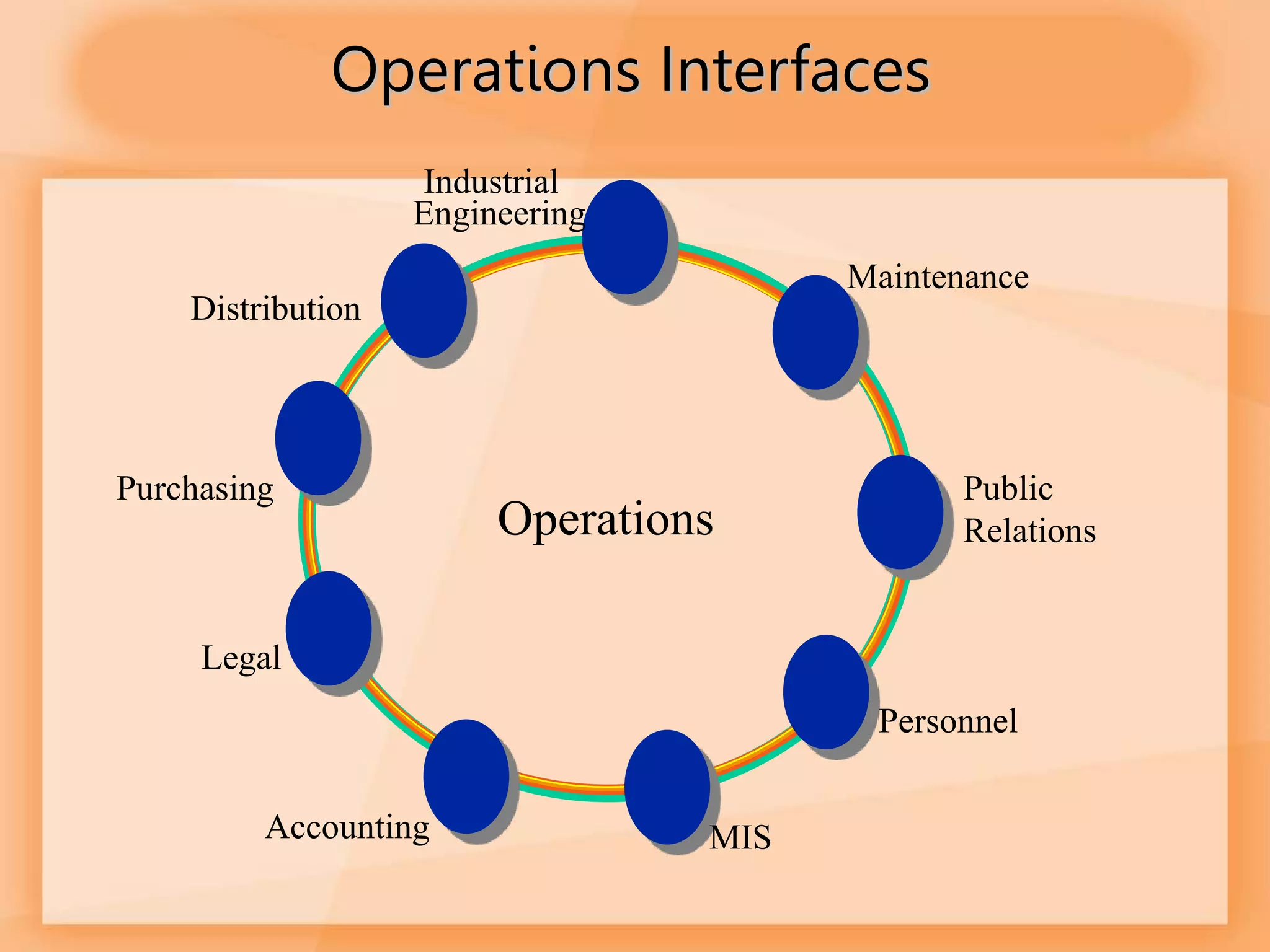

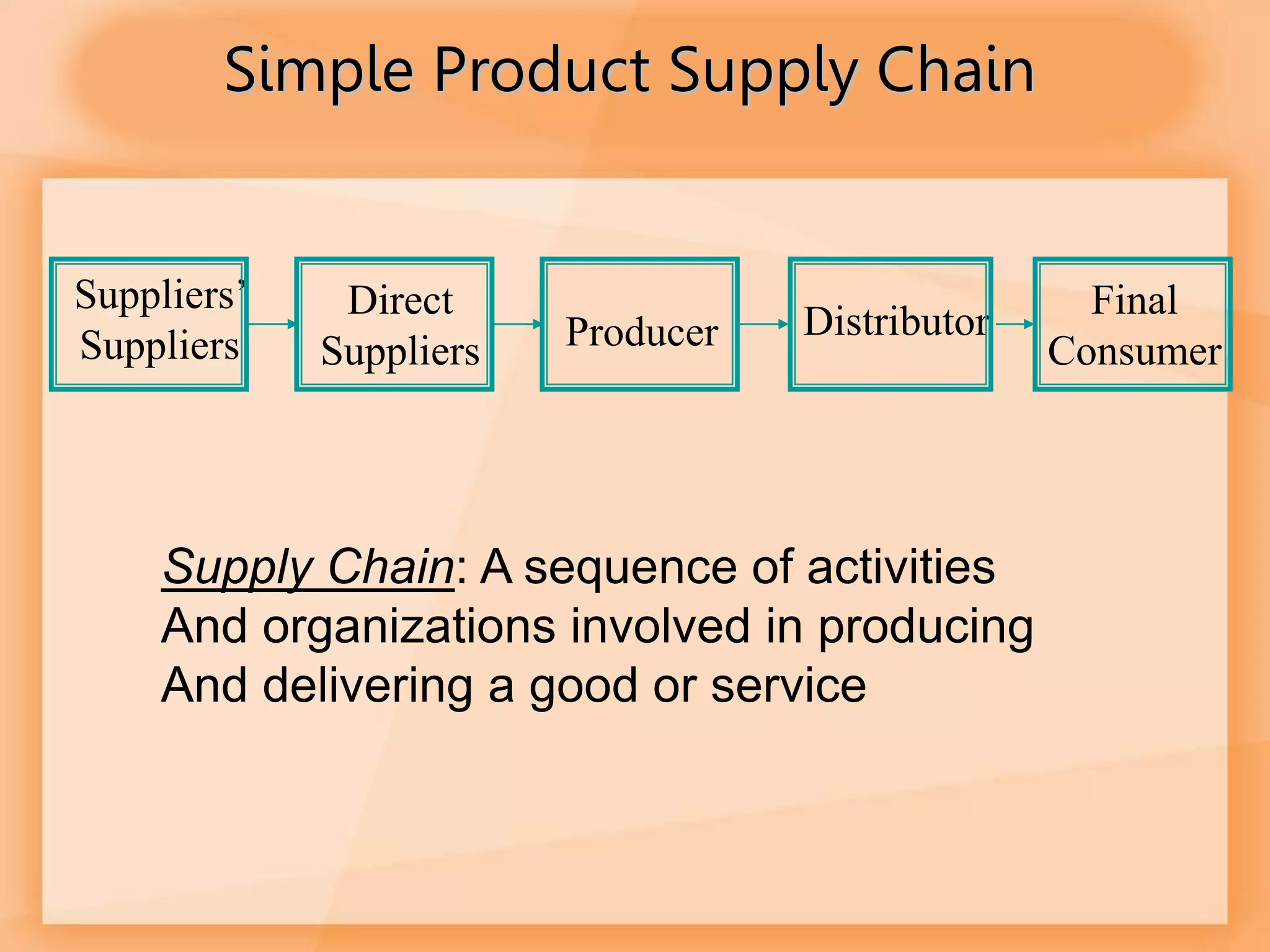

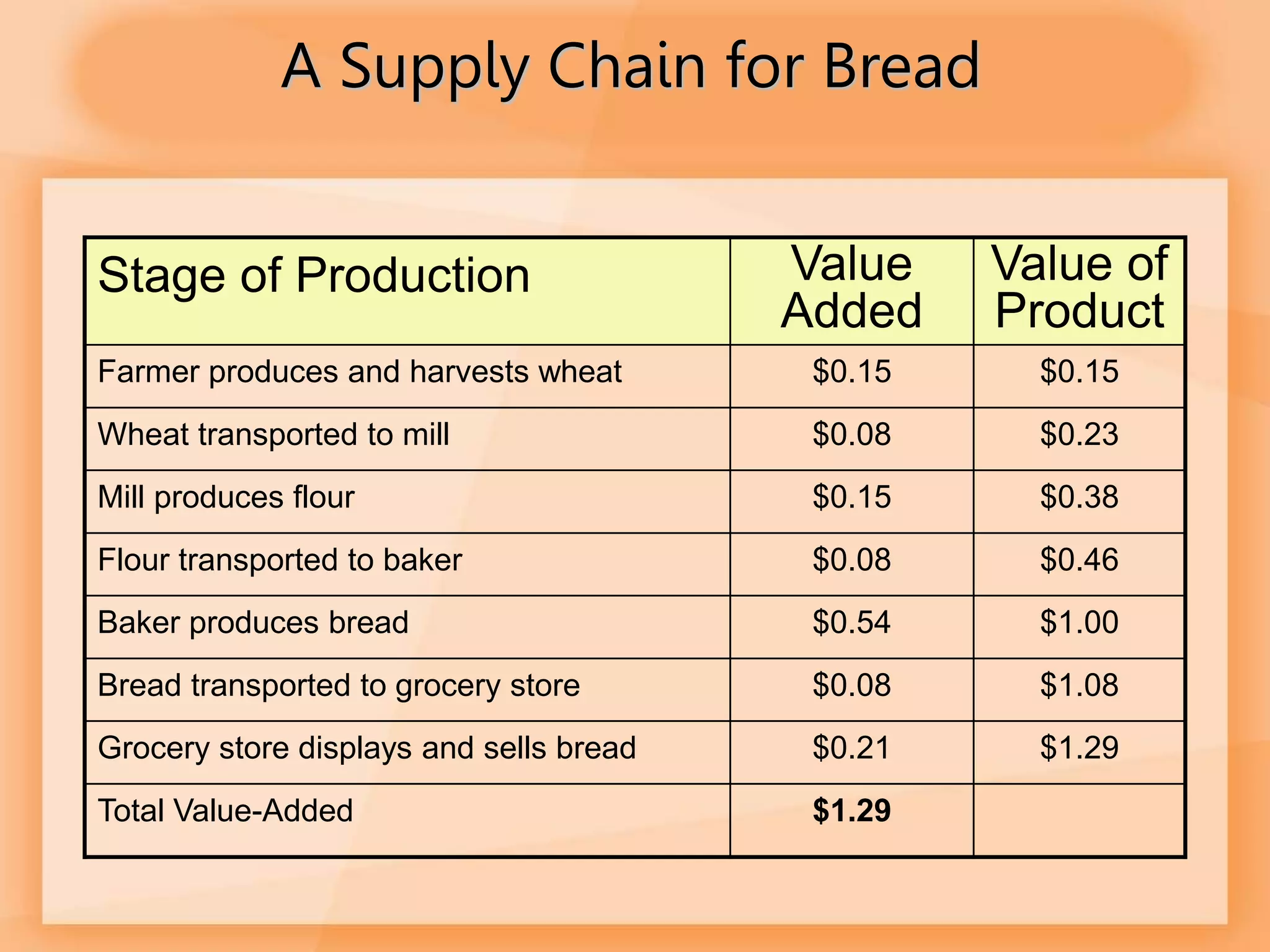

This document provides an introduction to operations management. It defines operations management and describes the three major functional areas of organizations: finance, marketing, and operations. It compares manufacturing and service operations and discusses the operations function. The document outlines several learning objectives related to operations management concepts like production systems, decision making, the evolution of the field, and current trends. It provides definitions and examples of key operations management terms.