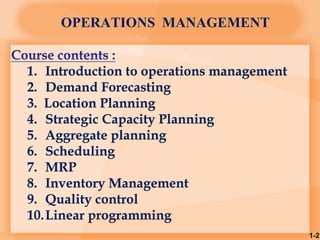

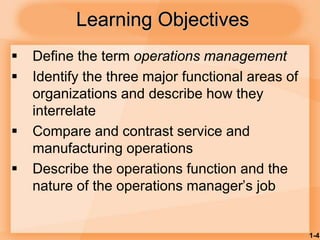

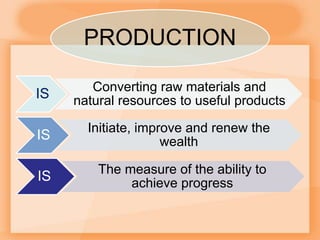

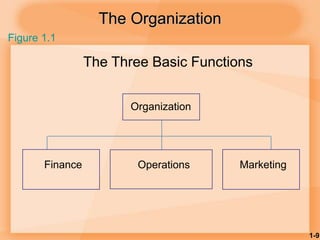

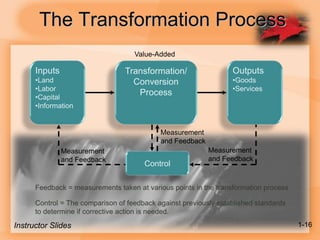

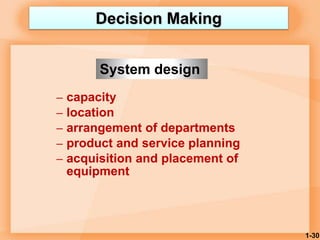

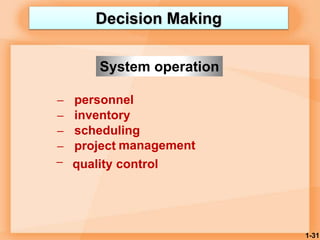

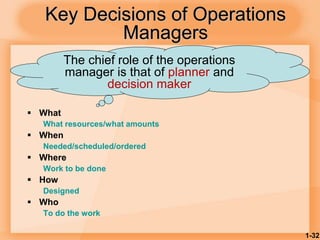

The document discusses key concepts in operations management. It covers 10 topics: 1) introduction to operations management, 2) demand forecasting, 3) location planning, 4) strategic capacity planning, 5) aggregate planning, 6) scheduling, 7) MRP, 8) inventory management, 9) quality control, and 10) linear programming. It defines operations management and describes the role of operations managers in decision making, including decisions related to system design and system operation.