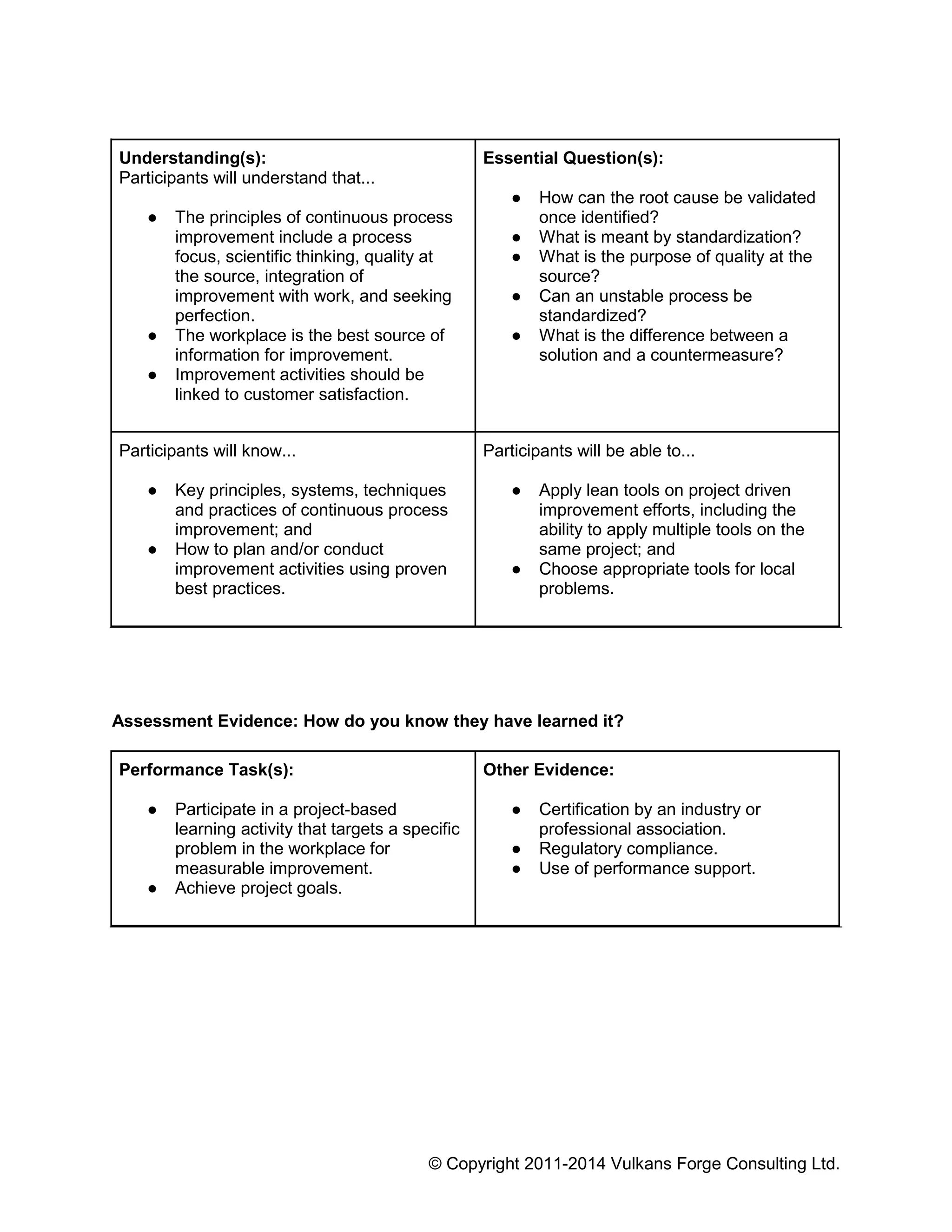

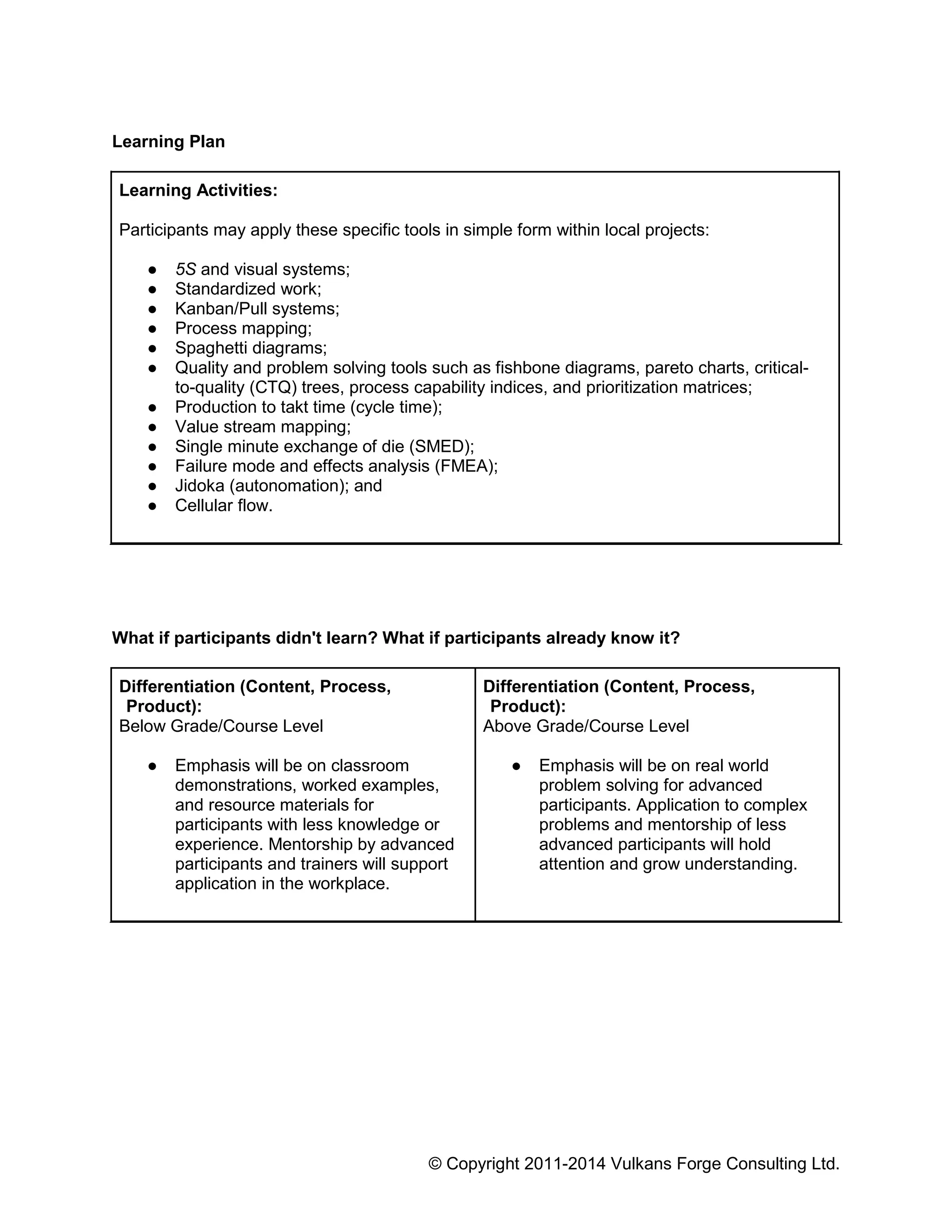

The document outlines a 32-hour training course focused on operational excellence for 4 to 20 employees, aimed at implementing continuous process improvement principles and tools. It specifies outcomes such as improved employee skills and enhanced financial performance for businesses, along with assessments including project-based learning and certification. Key topics include lean tools application, customer satisfaction linkages, and differentiation strategies based on participant knowledge levels.