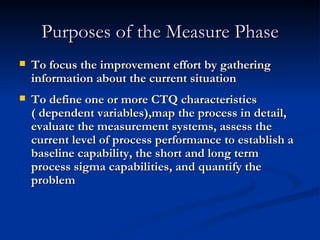

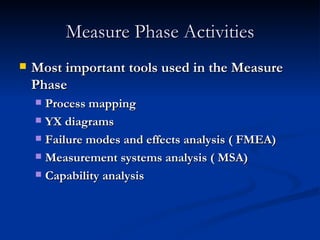

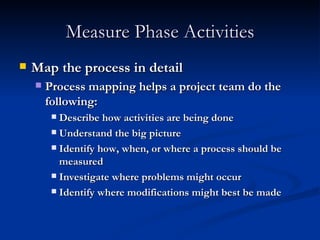

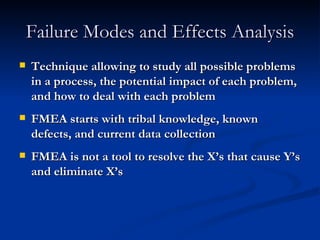

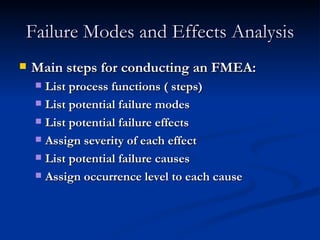

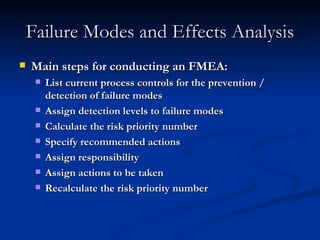

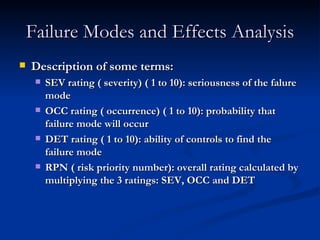

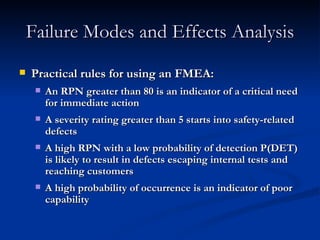

The document discusses the key activities and purposes of the Measure Phase in Six Sigma. These include mapping processes in detail to understand problems, conducting a Failure Modes and Effects Analysis to study possible process failures, measuring the current process capability to establish a baseline, and analyzing measurement systems to ensure accurate data collection. The goal is to focus improvement efforts by gathering information on the current process performance and identifying opportunities.