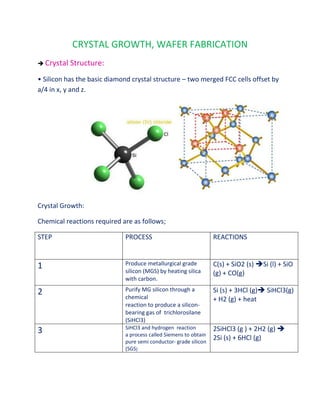

Crystal growth and wafer fabrication processes are described. Silicon has a diamond crystal structure. Metallurgical grade silicon is produced by heating silica with carbon, then purified through chemical reactions producing trichlorosilane gas. Czochralski crystal growth is the most common method, where silicon is melted and a seed crystal is used to start growth of a large, pure single crystal for wafer production. Important parameters like pull rate, temperature and rotation must be carefully controlled during crystal growth.