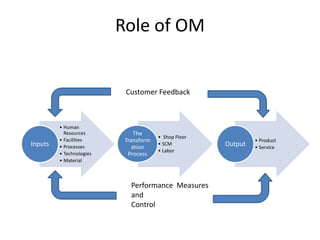

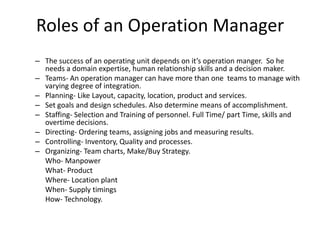

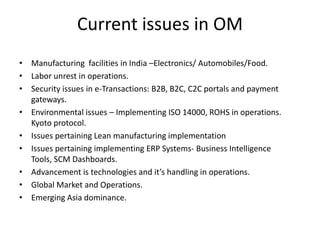

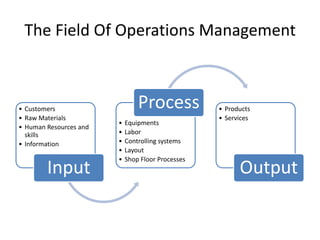

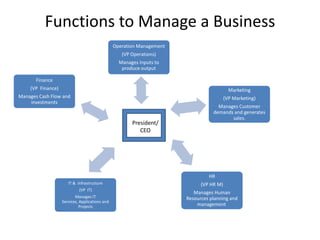

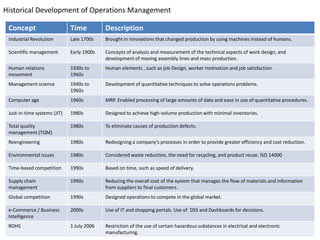

The document discusses key topics in operations management, including the roles and functions of operations managers, historical developments in the field, characteristics of manufacturing and service operations, and current issues facing operations management such as globalization, technology, the environment, and supply chain management. It provides definitions and descriptions of operations management, production systems, and the various departments involved in managing business operations from a strategic to tactical level.

![Various departments in Operations Management

[Assignment 1- Try to answer and fill the column to help your favorite co.]

General Decisions to be made Decisions specific to product or service Department

What are the unique features of the Operations strategy

Decision

Strategic

business that will make it competitive?

What are the unique features of the Product design

product?

What are the unique features of the Process selection

process that give the product its

unique characteristics?

What sources of supply should we use Supply chain

to ensure regular and timely receipt of managements

the exact materials we need? How do

we manage these sources of supply?

How will managers ensure the quality Quality management

of the product, measure quality, and

identify quality problems?

What is the expected demand for the Forecasting

product?

Where will the facility be located? Location analysis

How large should the facility be? Capacity planning

How should the facility be laid out? Facility layout

What are the different jobs and how and Job design and work

who can do those tasks and measure the measurement

performance

Decision

Tactical

When will orders be Inventory

placed and how much will be kept in management

stock?

Who will work on what schedule? Scheduling](https://image.slidesharecdn.com/om001-120609112230-phpapp01/85/Om001-8-320.jpg)