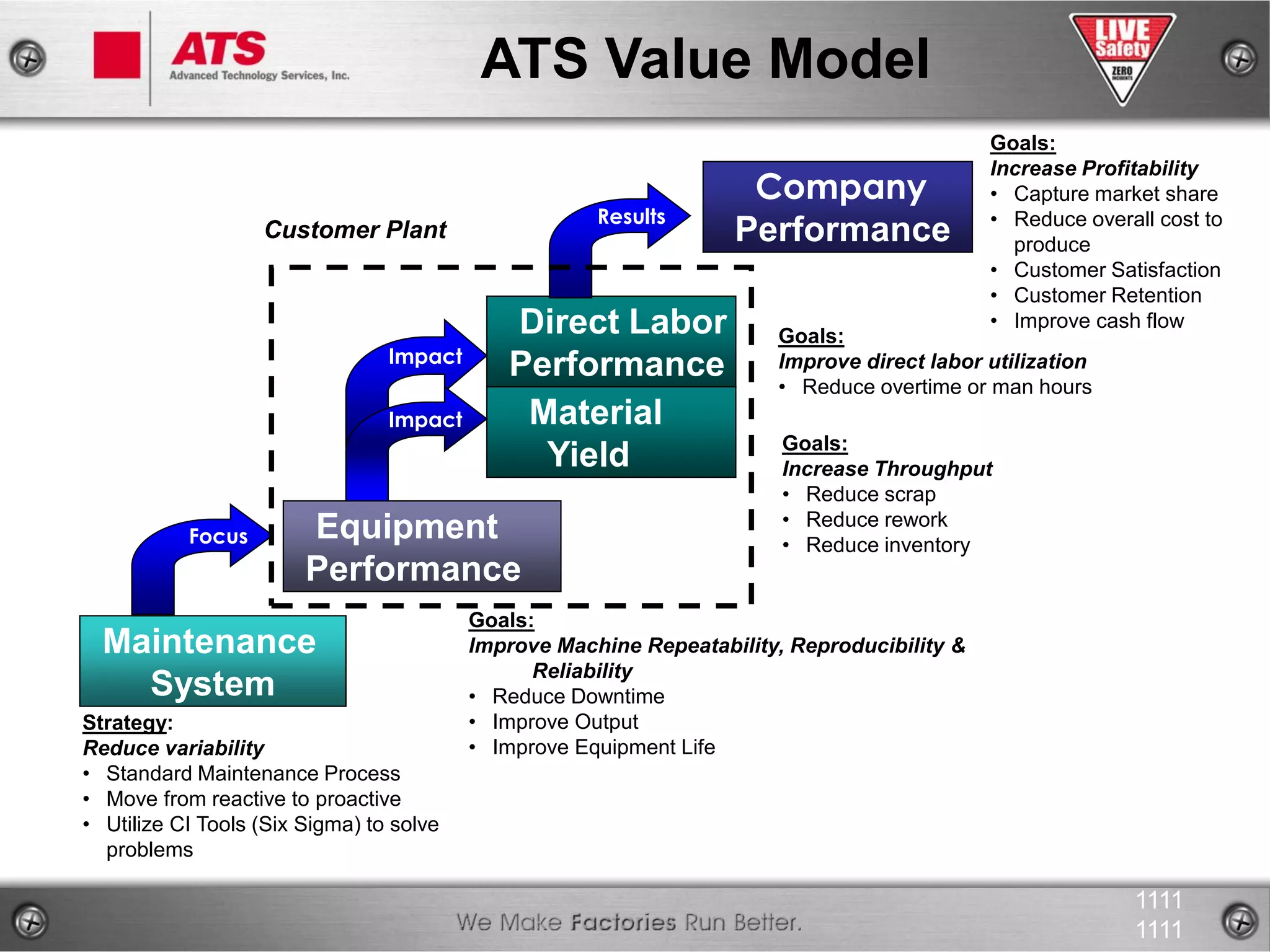

ATS provides factory maintenance services that help heavy equipment manufacturers run their factories better. Their mission is to be the market leader in delivering high-value solutions that improve factory operations. ATS has over 3,000 employees serving over 125 plants. Their full-service approach includes factory maintenance, parts repair, testing services, and IT support. Outsourcing maintenance to ATS can reduce costs, increase uptime and productivity, and allow manufacturers to focus on their core business.