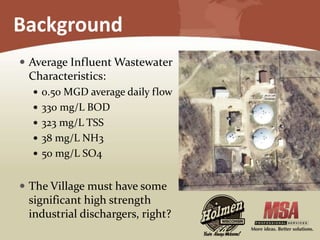

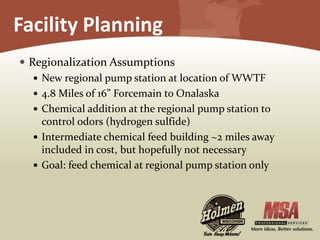

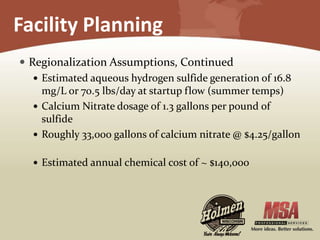

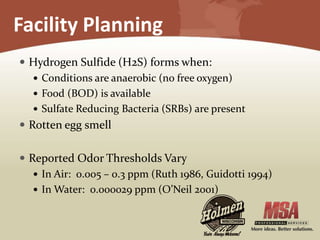

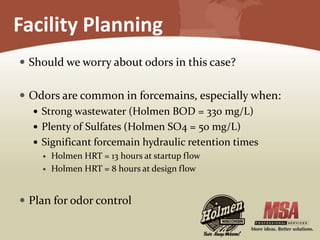

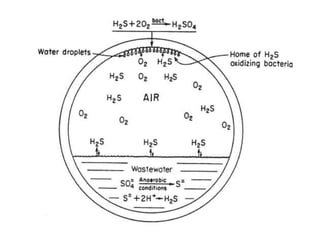

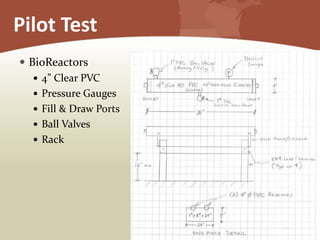

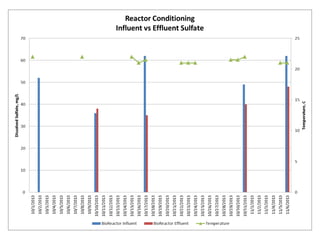

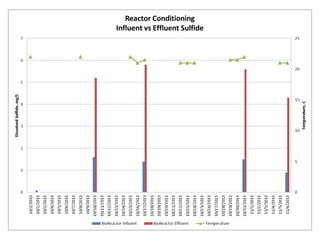

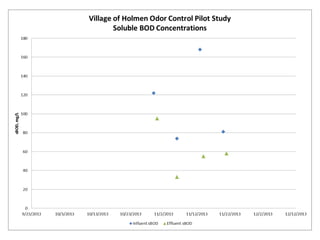

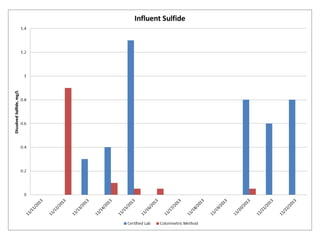

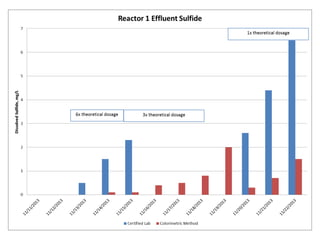

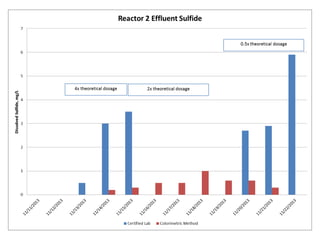

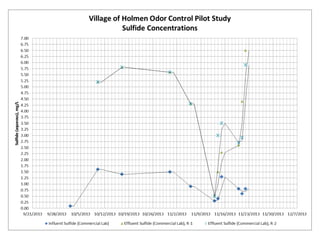

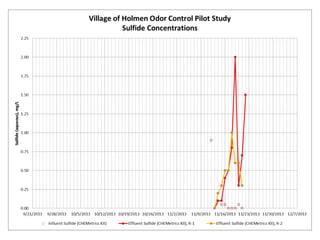

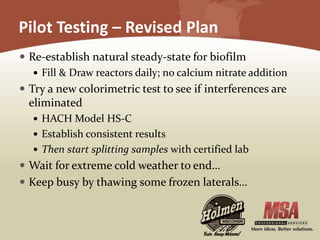

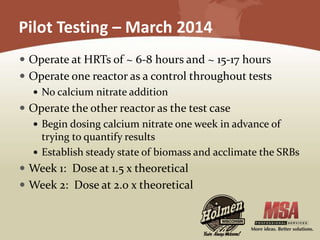

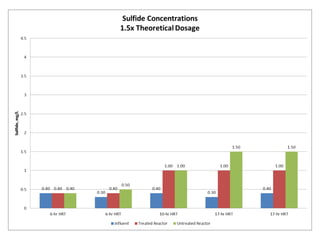

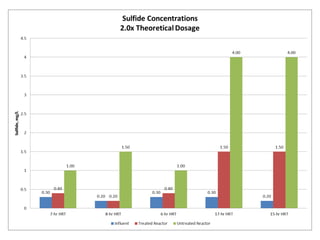

This document discusses a pilot project to test odor control in a proposed wastewater force main between Holmen, WI and Onalaska, WI. Bench-scale bioreactors were set up to mimic force main conditions and test calcium nitrate dosing. Initial results showed discrepancies between lab tests and colorimetric tests for sulfides. The testing plan was revised to better establish biofilm conditions before continuing dosage tests, which have shown promising trends so far in reducing sulfides. Further long-term testing is needed, especially in summer.