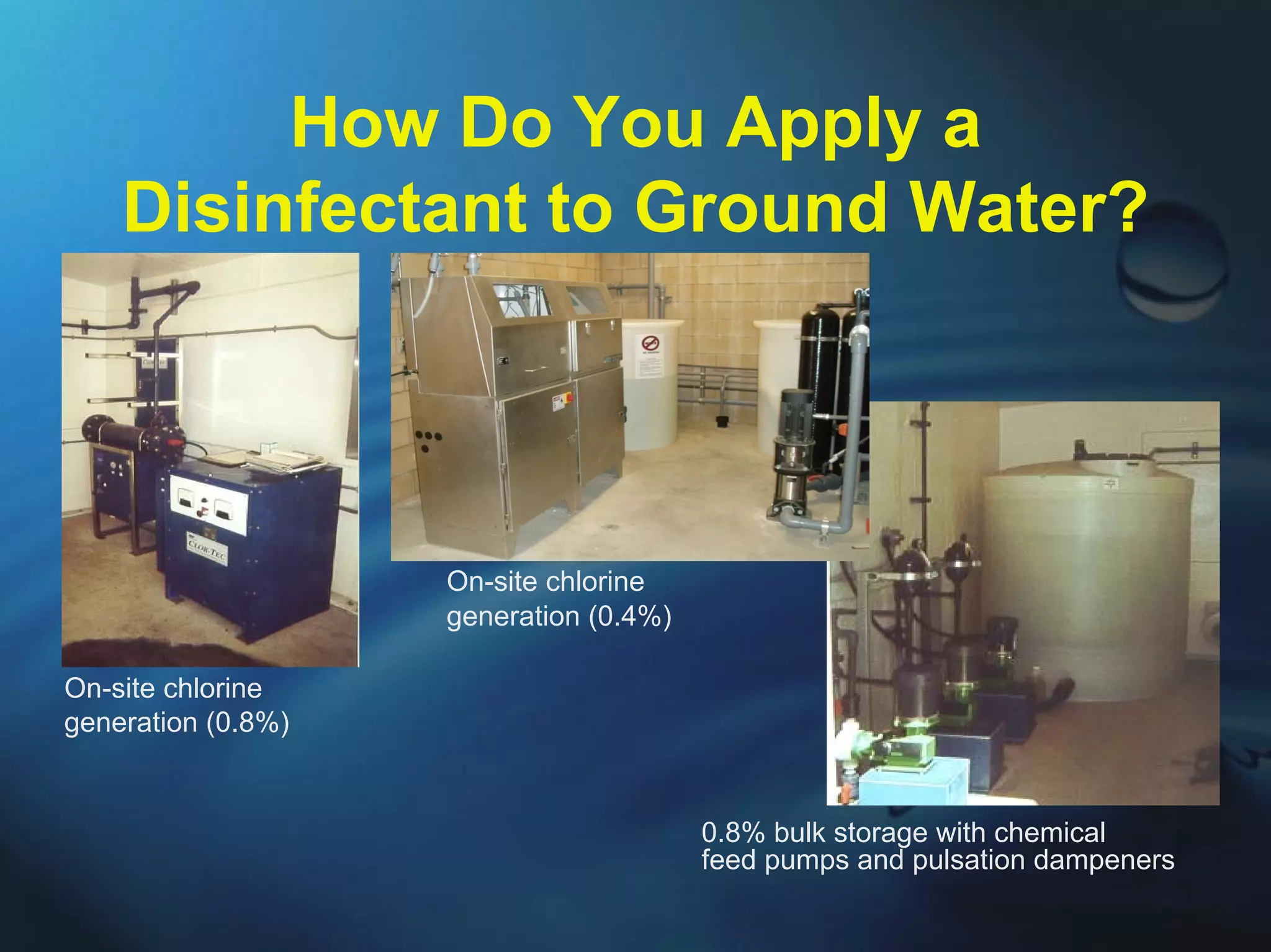

The document discusses the key requirements and challenges of complying with the US Groundwater Rule for public water systems, including conducting sanitary surveys, monitoring source water quality, ensuring 4-log treatment of viruses, and maintaining accurate documentation and reporting. It provides an overview of how systems can evaluate their sources and treatment capabilities to meet the rule. The document also describes various methods that groundwater systems can use to apply disinfectants to achieve the required 4-log inactivation or removal of viruses.