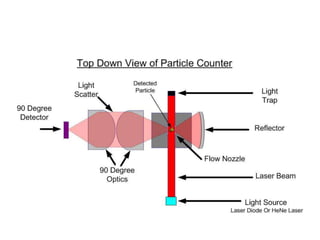

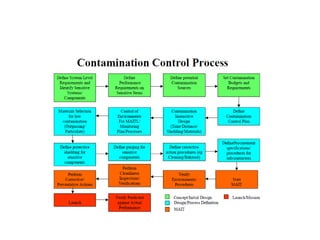

Particle counters and spectrographic analysis are used to analyze oil, fuel, coolant, and other fluid samples. They identify and quantify elemental constituents in sizes ranging from 1-200 microns. Common analyses include wear metals, additives, contaminants, and particle counts. Proper sampling requires operating equipment to temperature, using supplied kits, and thoroughly mixing and labeling samples for shipping to a lab for analysis. Test results are compared to baselines to evaluate wear elements, additives, and physical properties.