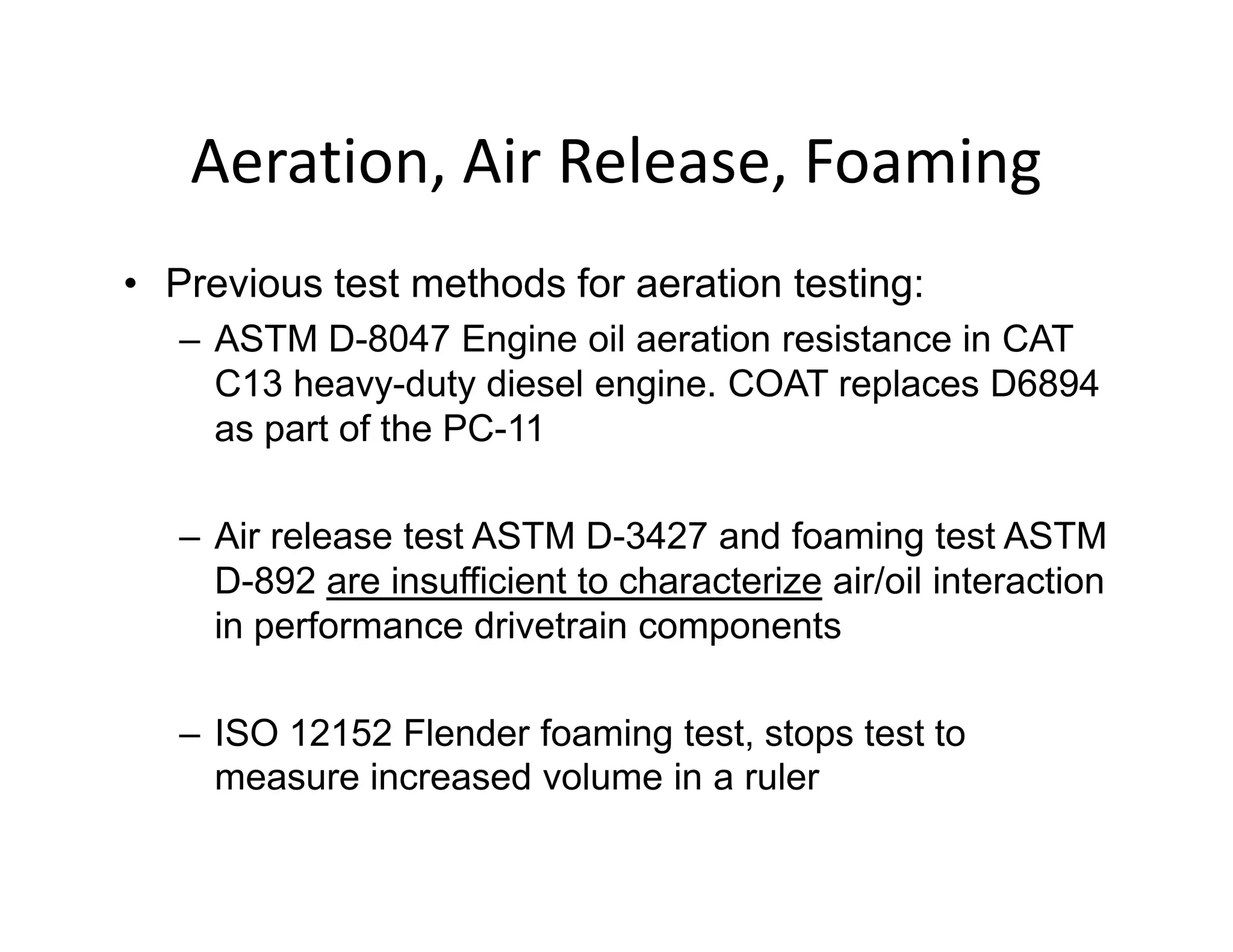

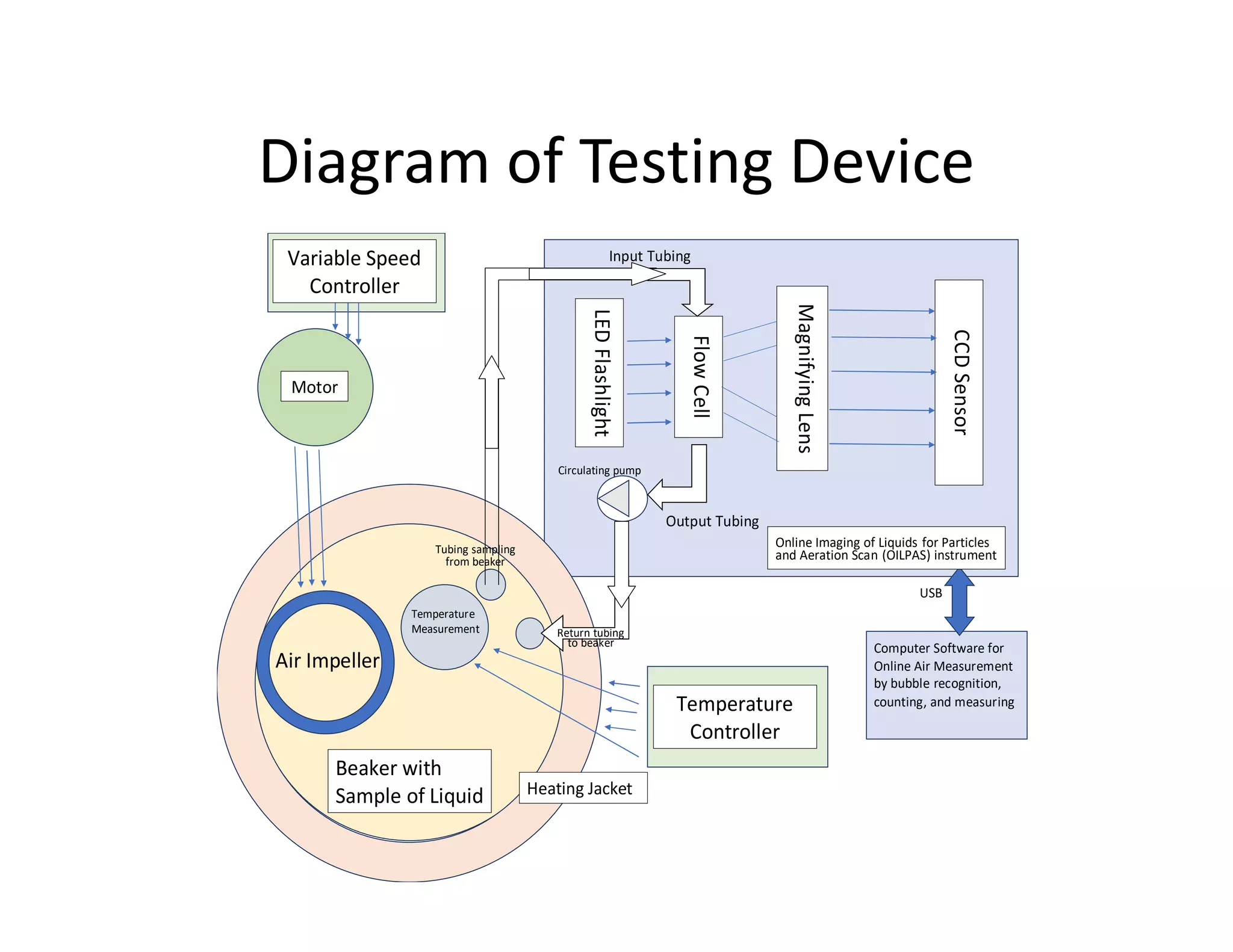

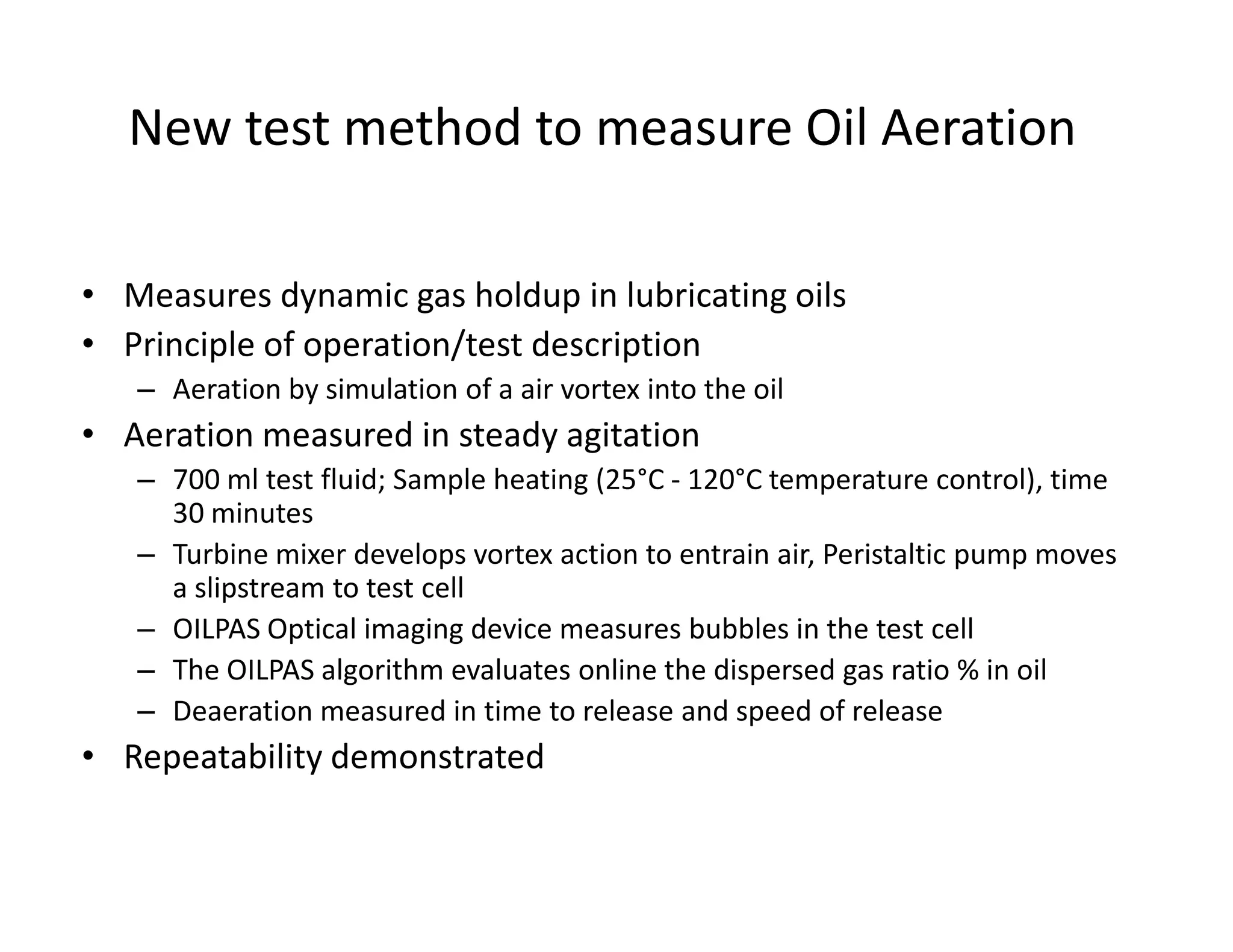

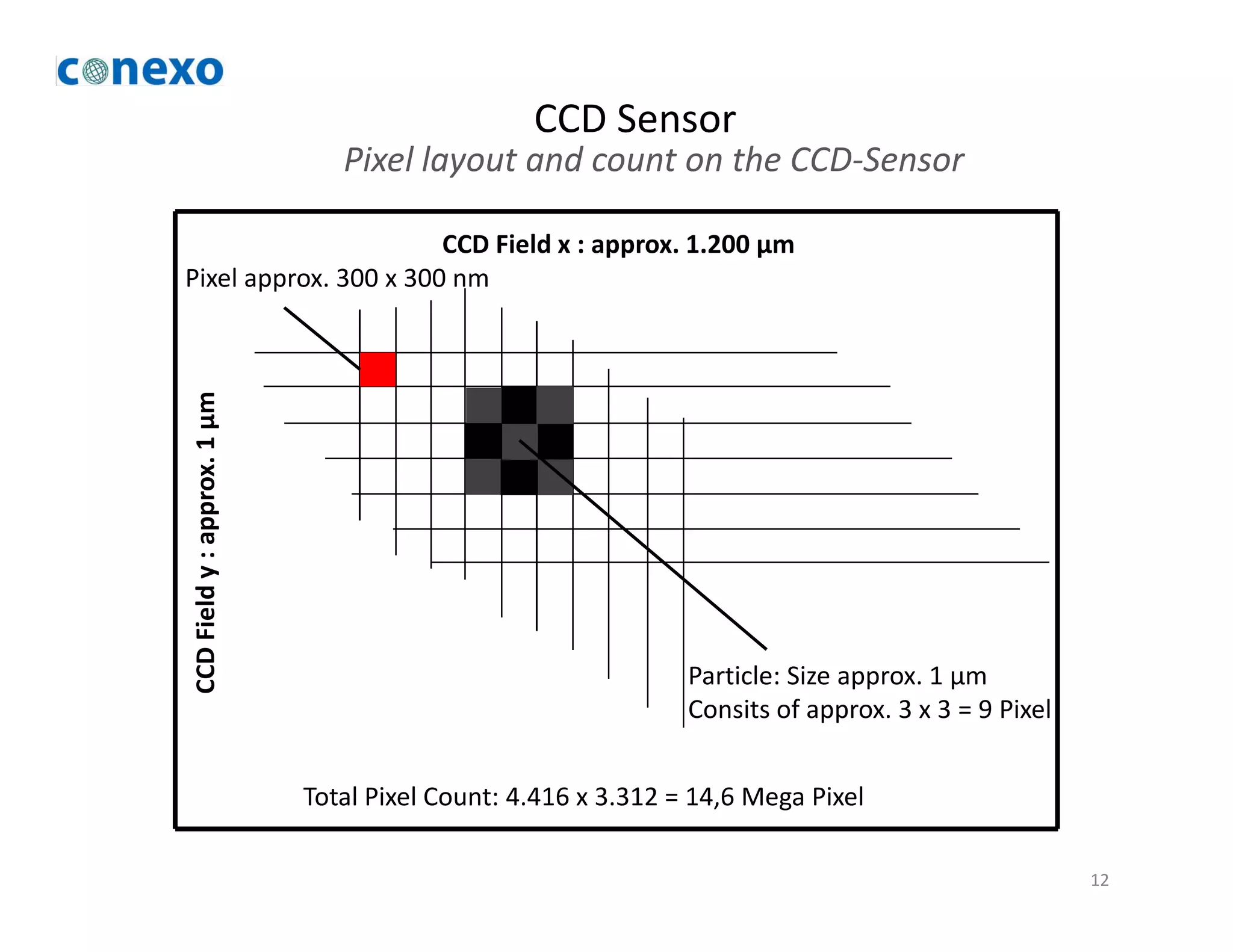

1) The document describes a new test method called OILPAS that measures engine oil aeration through optical imaging of bubbles in a test cell.

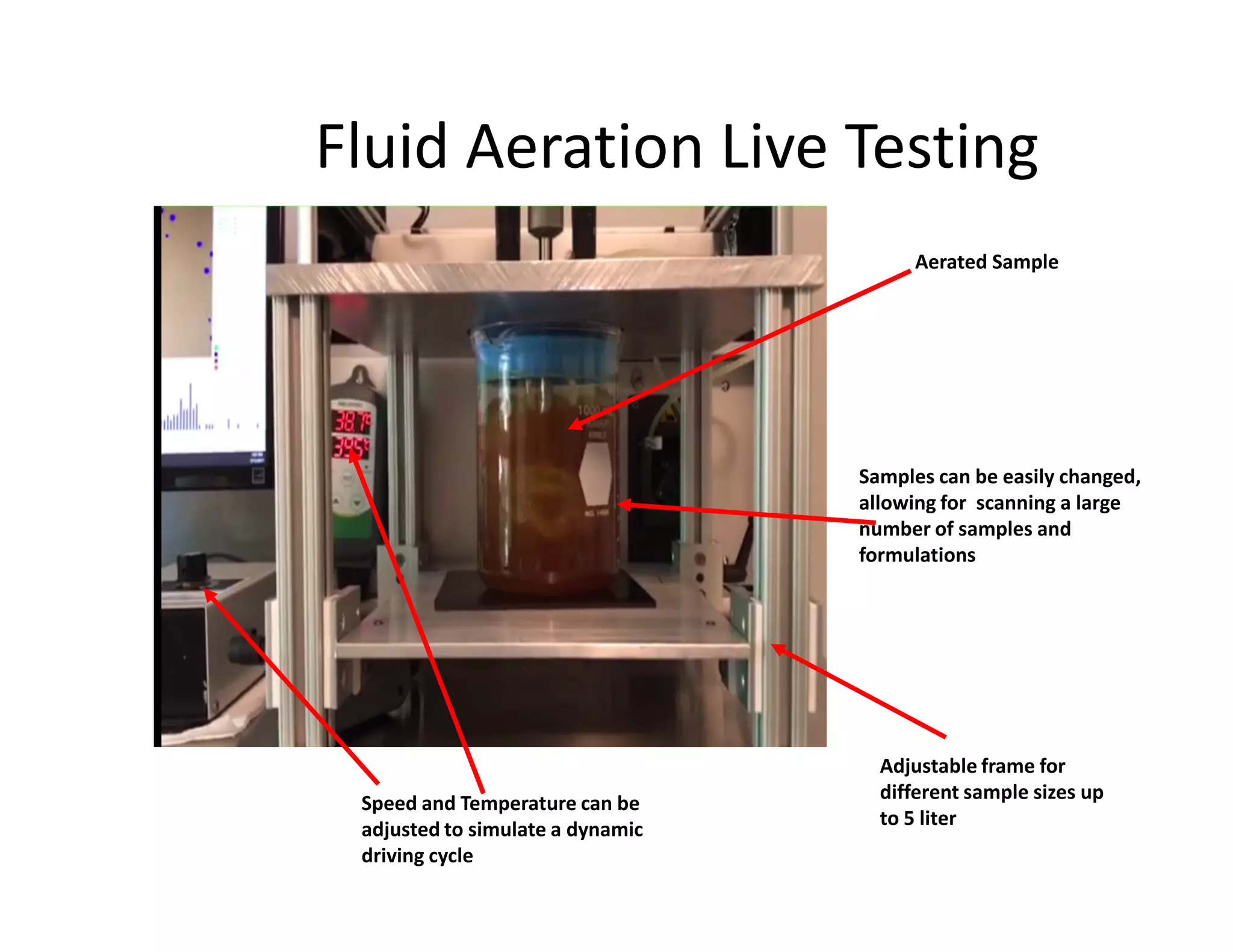

2) The OILPAS method dynamically aerates oil samples through agitation and measures the amount of dispersed gas as well as the time required for gas release.

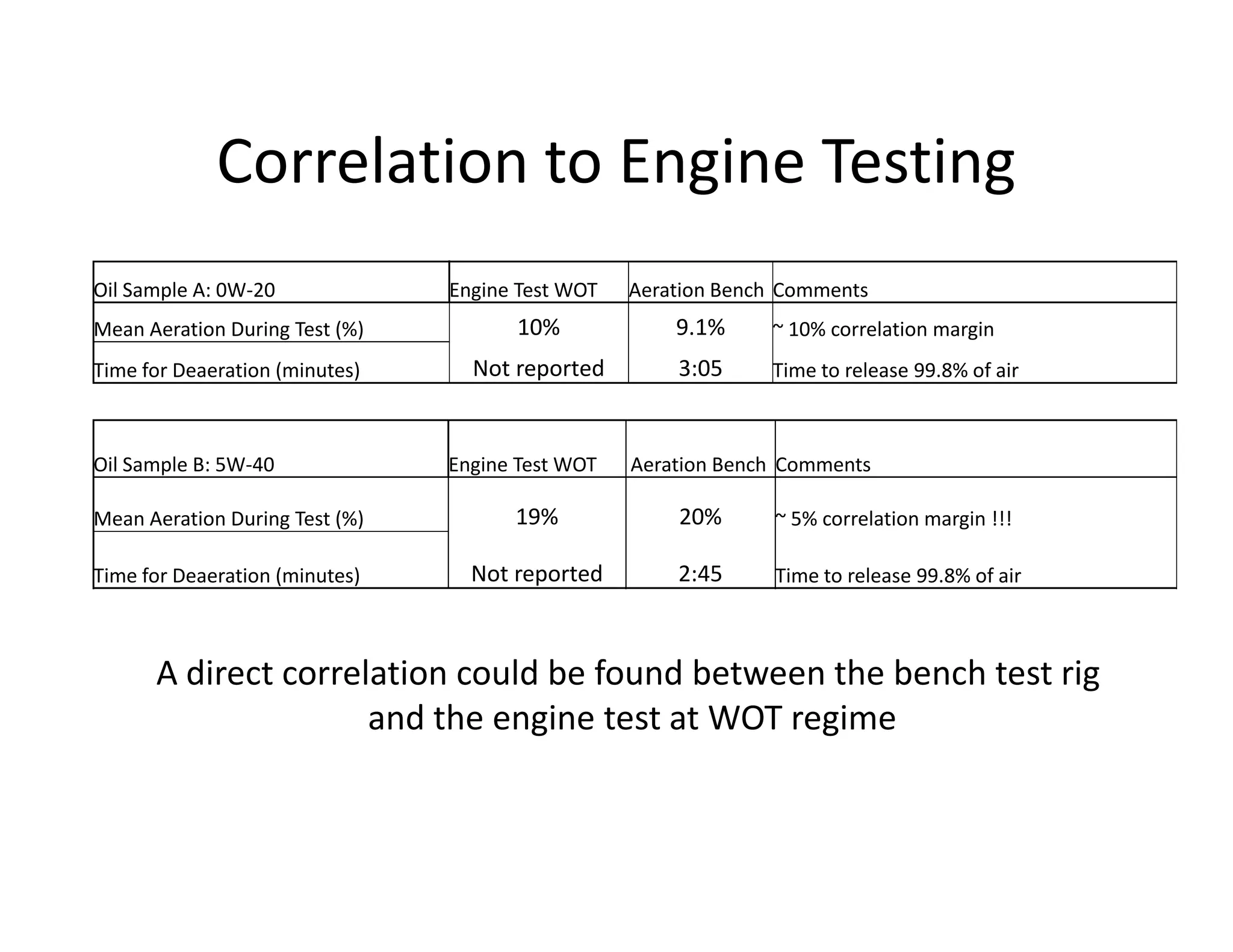

3) Test results on various engine oils showed correlations between OILPAS measurements of aeration and deaeration to results from engine tests, demonstrating its effectiveness as an evaluation method.

![Time-Resolved measured data

schematic representation based on the volume of bubbles

time

Picture n Pic. n+1 Pic. n+2 Pic. n+3 Pic. n+4

bubbles:

evaluation n

bubbles:

evaluation n+1

bubbles:

evaluation n+2

bubbles:

evaluation n+3

bubbles:

evaluation n+4

OILPAS Measurement System 14

bubbles:

number = 10

surf. = 33203µm²

Volume = 1546 pl

bubbles:

number = 3

surf. = 15924 µm²

Volume = 891 pl

bubbles:

number = 6

surf. = 19615 µm²

Volume = 858 pl

bubbles:

number = 5

surf. = 22718 µm²

Volume = 1196 pl

bubbles:

number = 4

surf. = 12370 µm²

Volume = 524 pl

n-1 n n+1 n+2 n+3 n+4

0

500

1000

1500

2000

Blasenvolumen[pl]

From the bubble volume by a constant factor, a concentration can be calculated

and correlated to headspace methods FEV.](https://image.slidesharecdn.com/oilaerationscreeningtestmethod-180812171820/75/Oil-aeration-screening-test-method-14-2048.jpg)