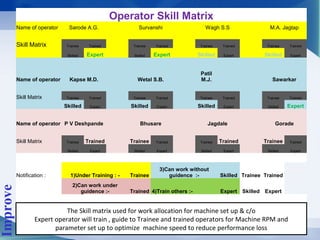

This project aimed to improve the productivity of the compression machine by 10% through a Six Sigma project. Key issues identified were availability losses from changeovers and breakdowns, and performance losses from machine settings and RPM. The project team implemented actions like skill matrices for operators, standardized checklists for RPM settings, and preventative maintenance schedules to reduce downtime. As a result, OEE improved from 44.11% to 56.81%, saving over 500 minutes of availability time per day and increasing annual tablet production by over 15 million tablets.