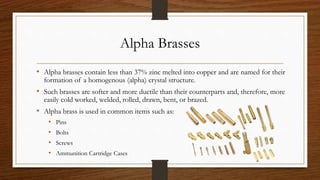

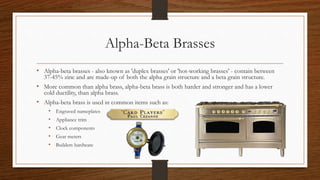

Brass is an alloy of copper and zinc. Varying the proportions of zinc and copper changes the properties of brass, allowing for both hard and soft varieties. Brass has been widely used since ancient times for decoration, utensils, and applications requiring low friction and corrosion resistance like locks and valves. The three types of brass crystal structures are alpha, beta, and alpha-beta brasses, which are distinguished by their zinc content and properties.