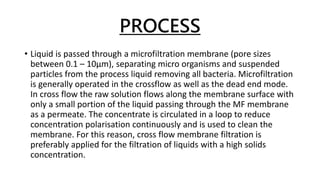

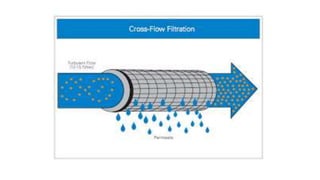

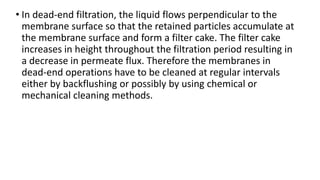

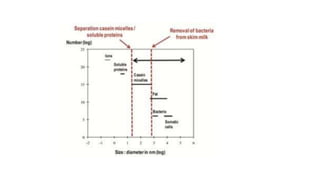

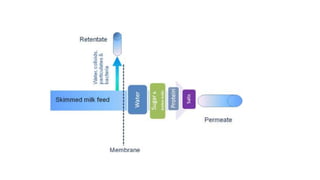

The document discusses non-thermal microfiltration (MF) processes in dairy technology, focusing on their application for bacterial reduction and protein separation in milk. MF effectively sterilizes milk by removing microorganisms and impurities without damaging its properties, providing advantages over heat treatments. The study aims to enhance the shelf life of milk through improved pasteurization and MF techniques while retaining flavor quality.