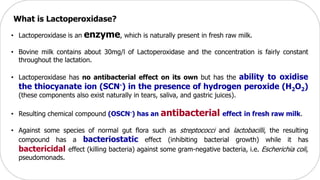

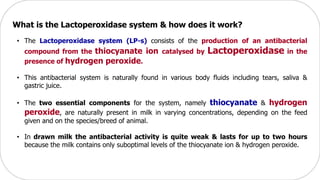

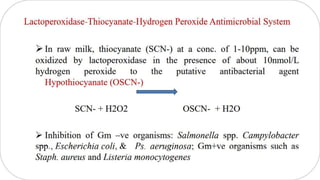

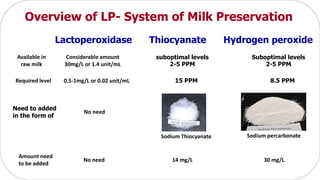

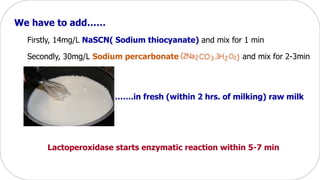

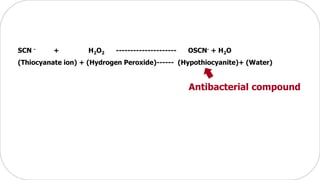

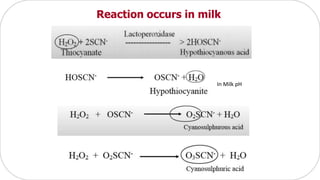

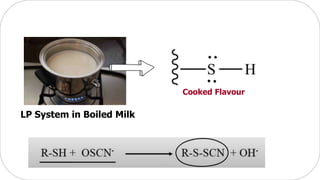

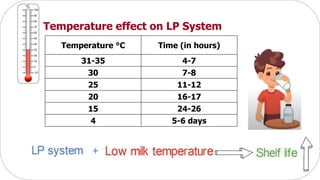

The lactoperoxidase system (lp-s) is a natural milk preservation method that relies on the enzyme lactoperoxidase, thiocyanate, and hydrogen peroxide to generate antibacterial compounds. This system can extend the shelf life of raw milk by up to 7-8 hours under tropical conditions, making it useful for transport and processing without refrigeration. Studies by the FAO/WHO have confirmed its safety for human and animal health when applied according to established guidelines.