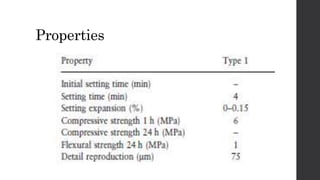

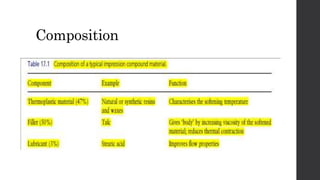

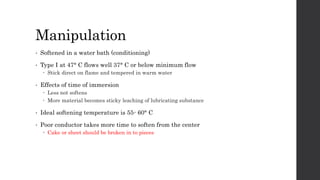

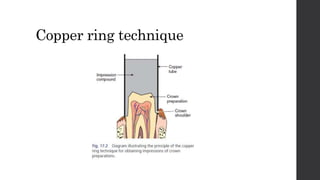

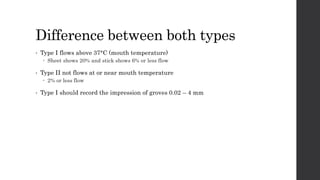

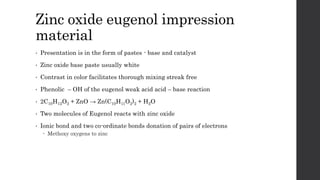

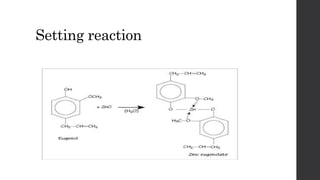

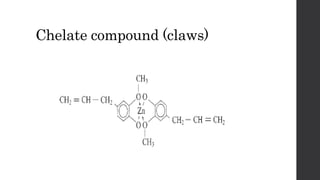

This document discusses rigid impression materials that are incapable of recording undercuts and often fracture or distort upon removal from the mouth. It focuses on impression plaster and compounds. Impression plaster sets rapidly but has low strength and is used for mobile soft tissues. Impression compound is a thermoplastic that comes in types for different purposes. It requires heating to the proper temperature for manipulation. Both materials can record fine details but lack elasticity and often fracture in undercut areas. The document also covers zinc oxide eugenol paste, which sets via an acid-base reaction and forms a chelate compound. It has low viscosity initially but sets to a rigid impression.