The document summarizes the industrial process for gear box manufacturing at a company. It has three main points:

1) The company was founded in 1958 and manufactures air compressors, pneumatic tools, gearboxes, and other industrial equipment. It has established global joint ventures and partnerships.

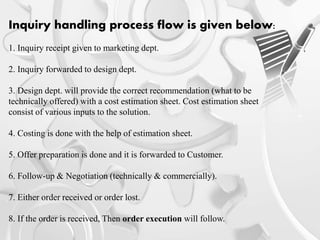

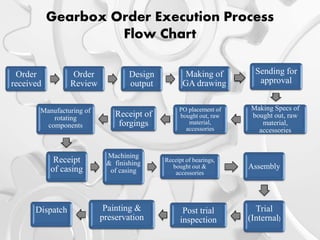

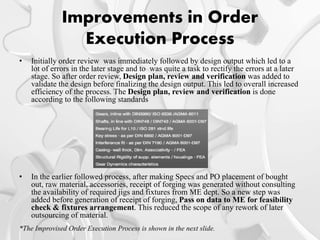

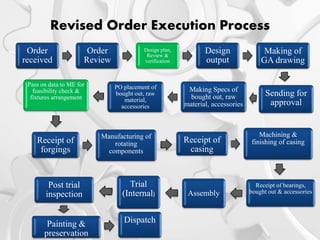

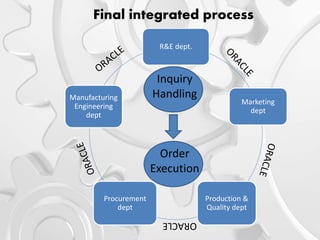

2) The standard process has three sub-processes: inquiry handling, order execution, and an ERP system. Inquiry handling involves receiving inquiries, cost estimation, and offering preparation. Order execution includes design, manufacturing, and assembly.

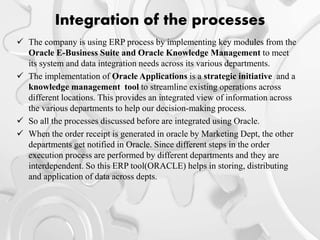

3) The processes were integrated using the company's Oracle ERP system. This allows data sharing between marketing, R&D, production, procurement, and other departments for improved