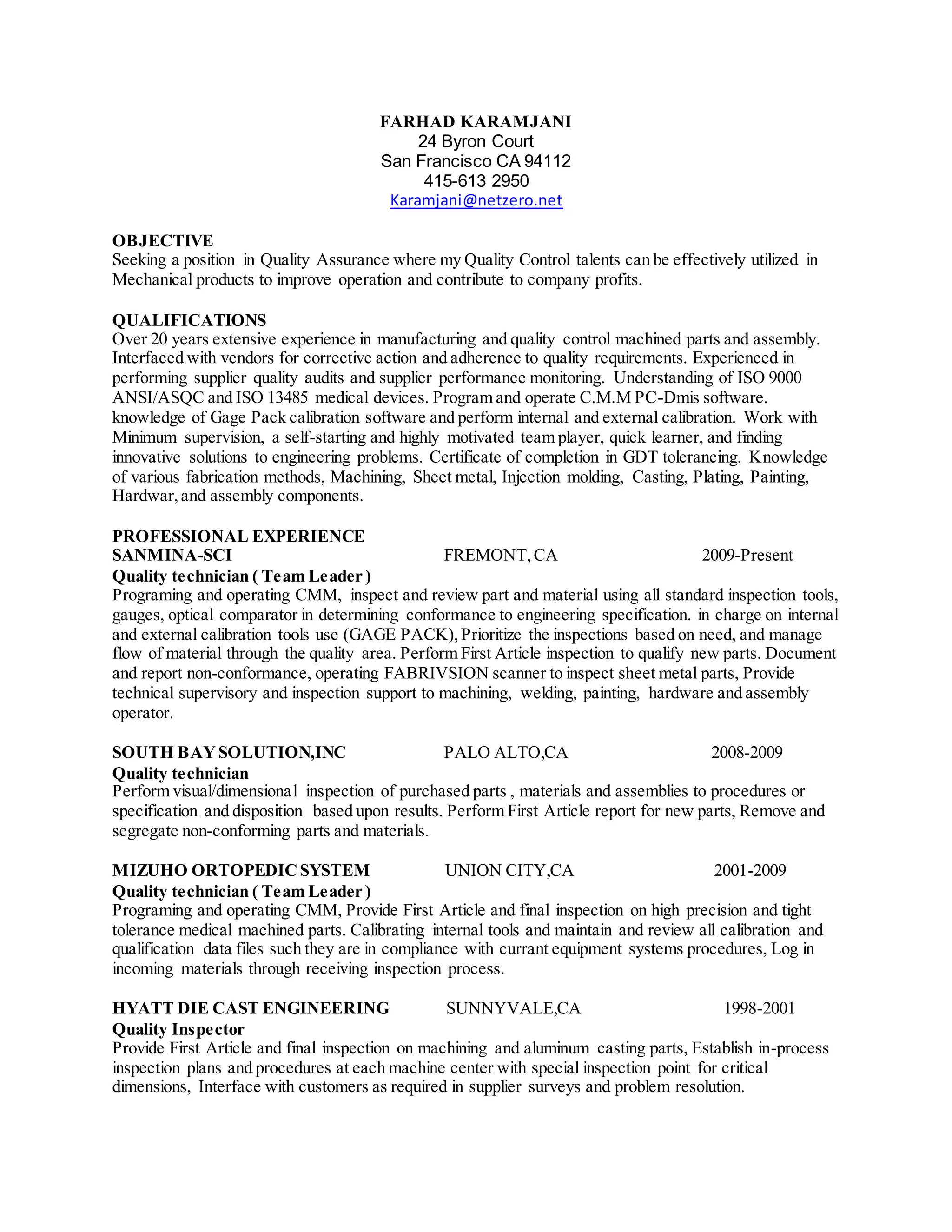

Farhad Karamjani has over 20 years of experience in quality control and assurance, seeking a position utilizing his skills. He has extensive experience performing inspections, audits, and monitoring to ensure adherence to quality standards like ISO 9000. Karamjani is proficient with inspection tools and calibration software, and has experience programming and operating CMM and Gage Pack calibration software. He has worked as a quality technician and team leader for several manufacturing companies, performing tasks like first article inspections, dimensional inspections, calibration, and ensuring compliance.