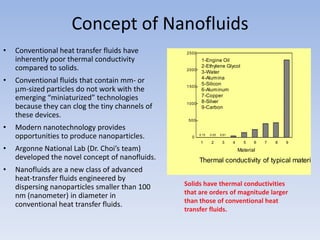

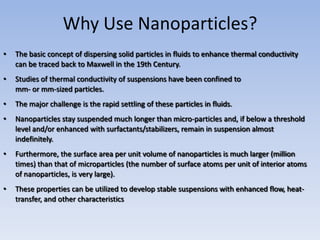

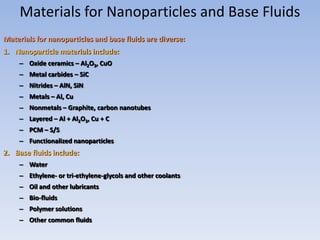

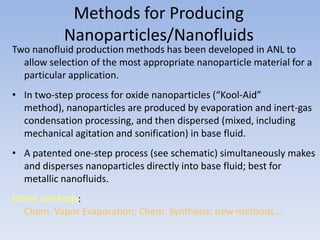

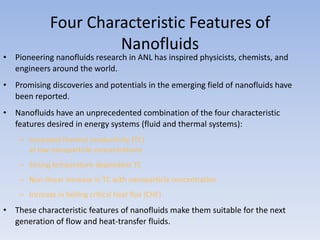

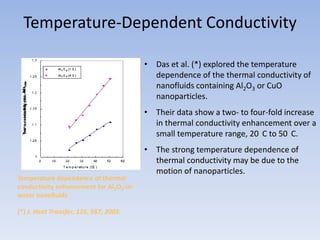

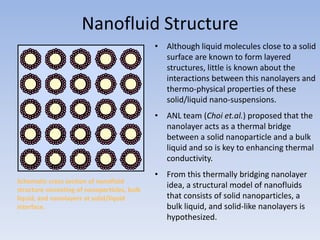

Nanofluids are suspensions of nanoparticles in base fluids that have been shown to have enhanced thermal conductivity and heat transfer properties compared to conventional fluids. Nanoparticles are smaller than 100nm and do not settle out of suspension like larger particles. Research at Argonne National Lab developed the concept of nanofluids and two methods for producing them - a two-step process for oxides and a one-step process for metals. Nanofluids have four key features - increased thermal conductivity at low nanoparticle concentrations, strong temperature dependence, nonlinear increases with concentration, and increased critical heat flux. Further research is needed to understand nanofluid structure and dynamics at the nanoscale.