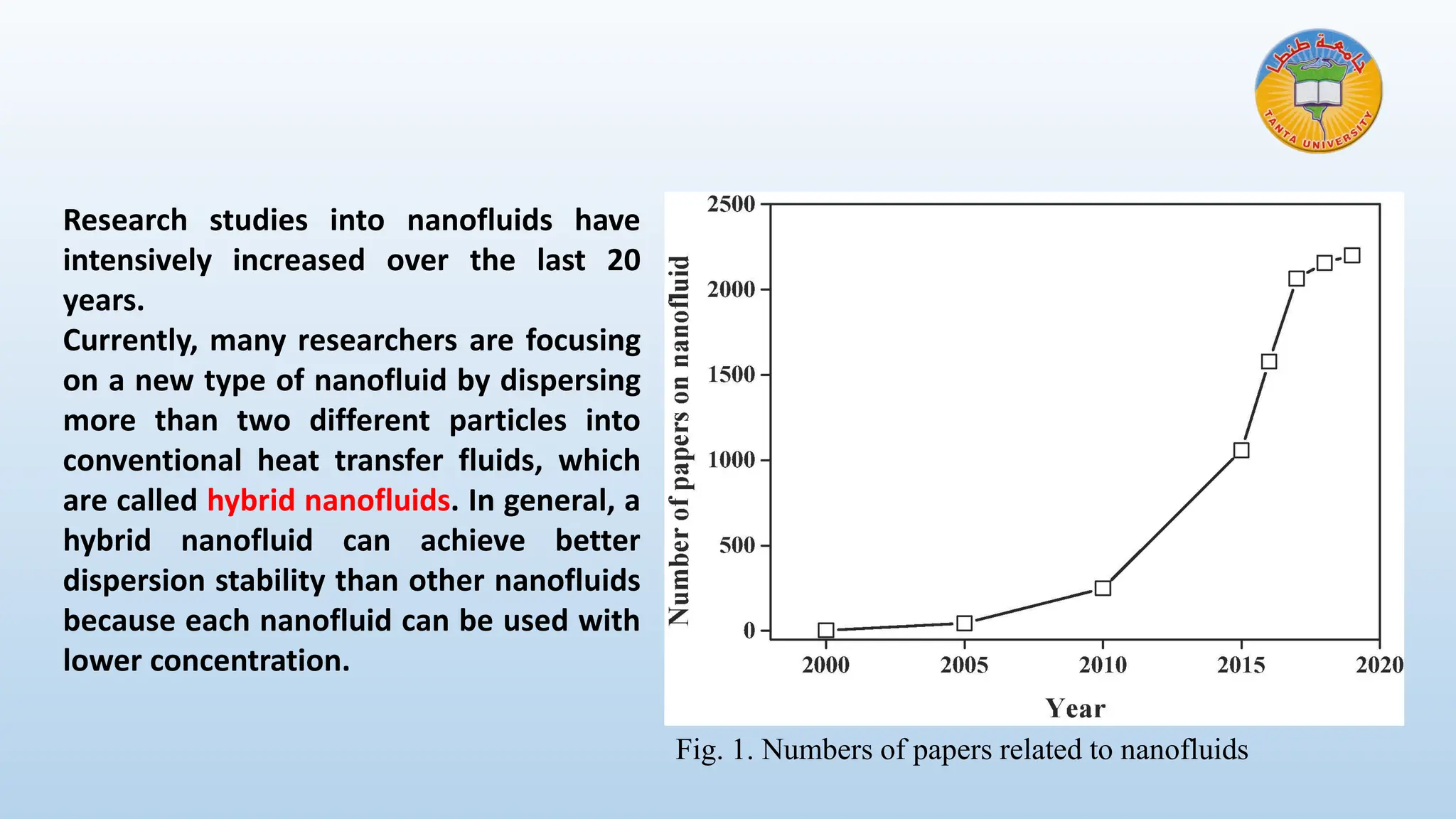

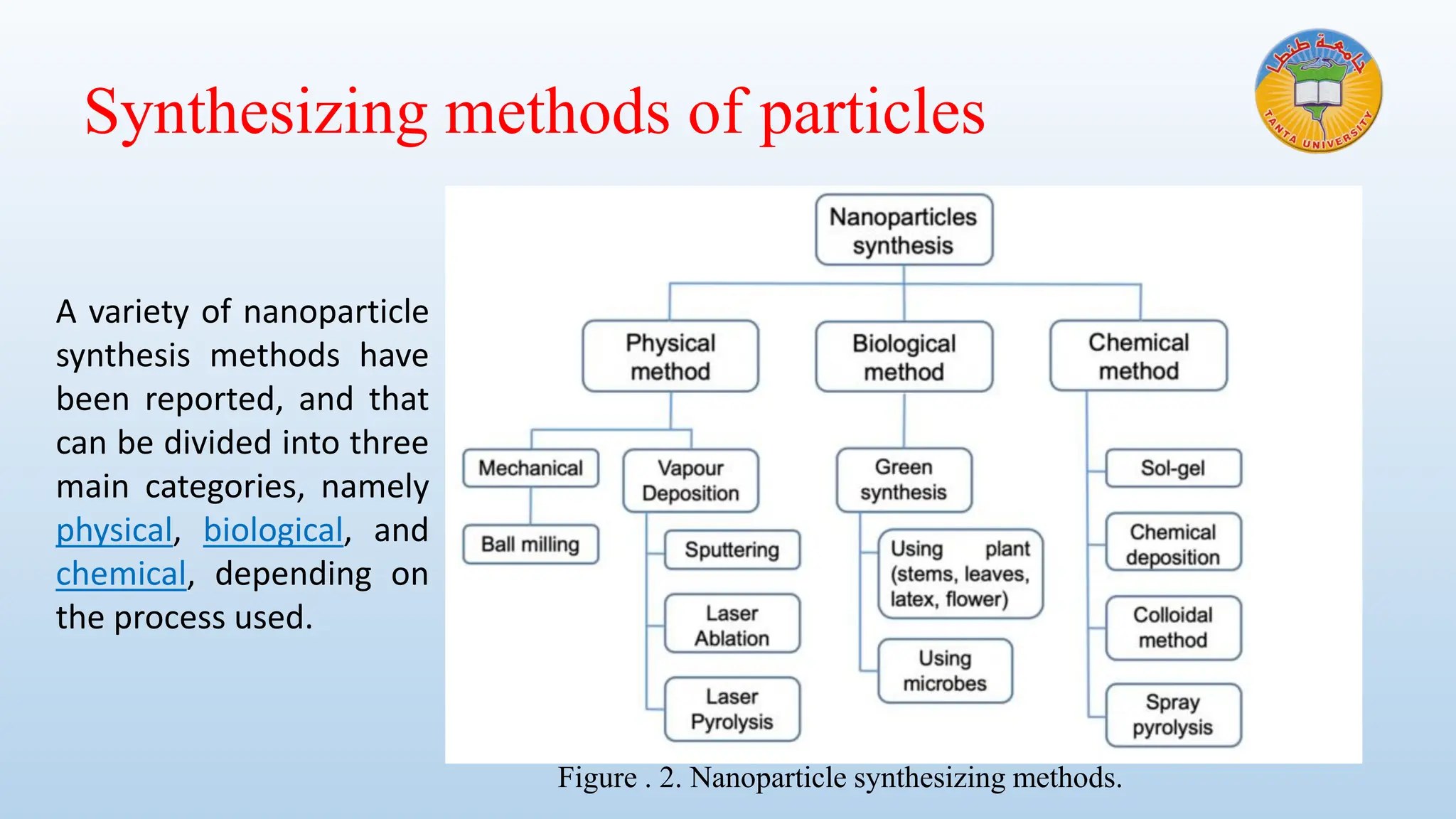

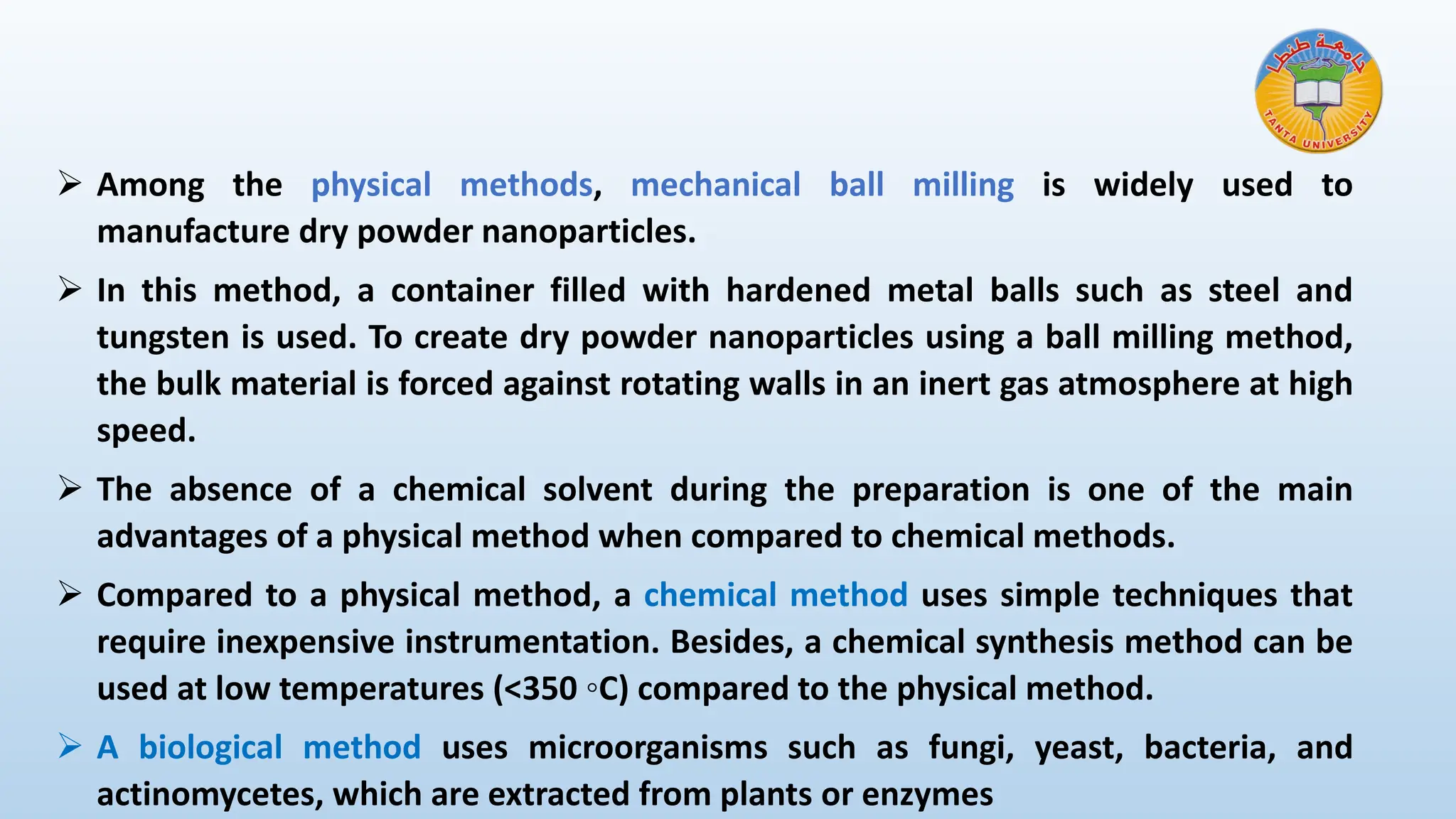

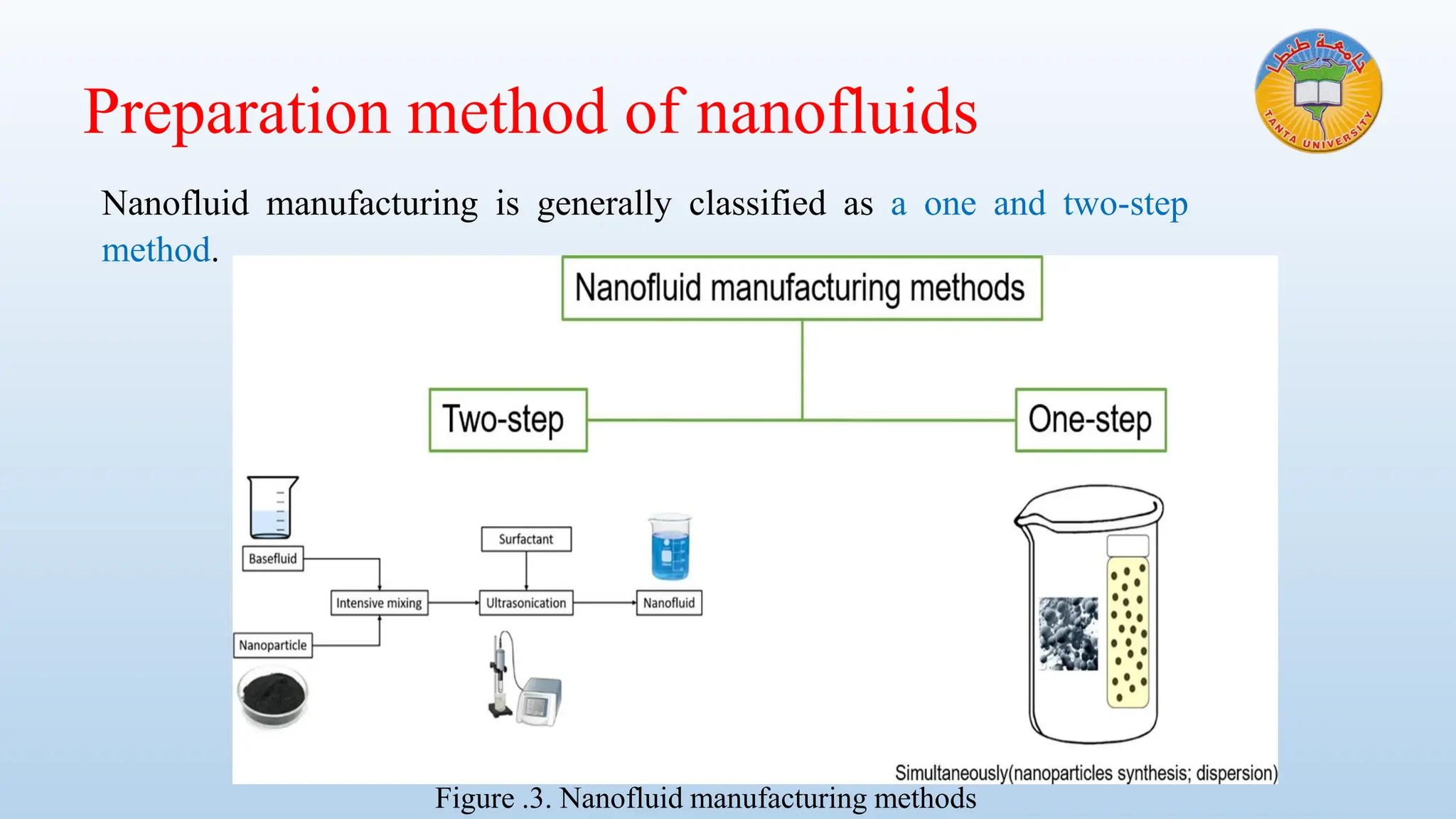

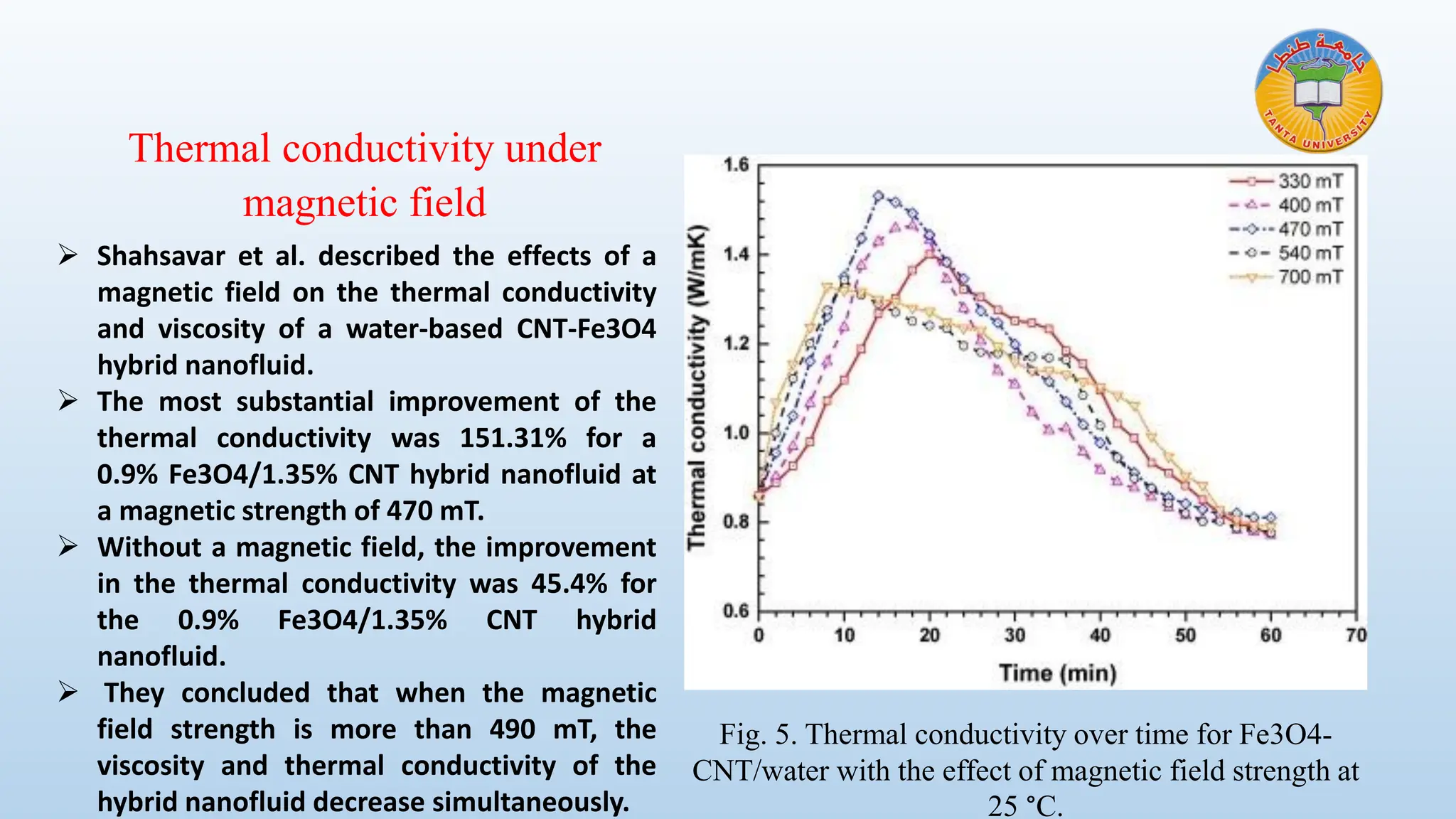

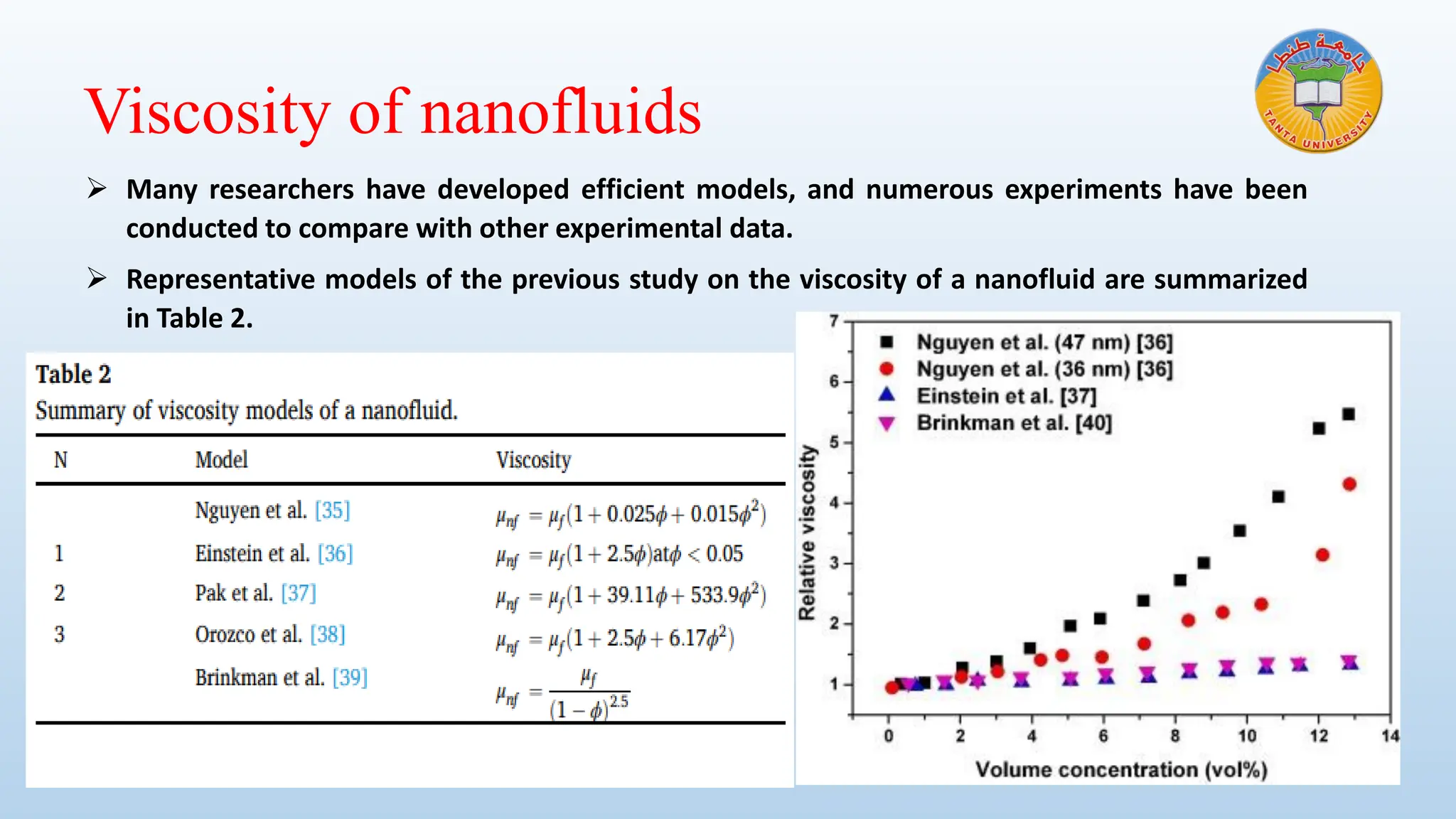

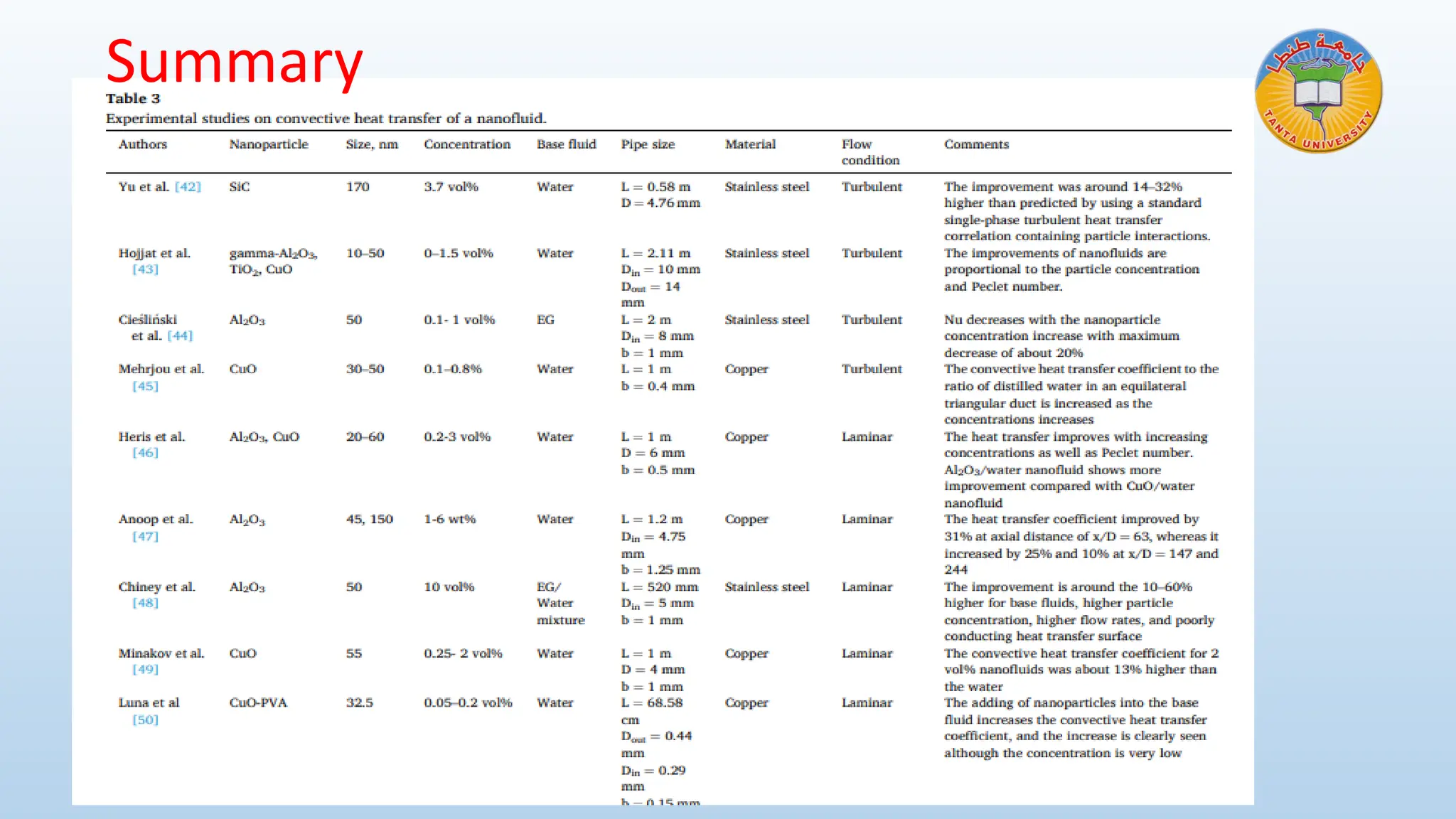

The document discusses heat transfer enhancement through the use of nanofluids, which are suspensions of nanoparticles in conventional fluids, aiming to improve thermal conductivity and convective heat transfer performance. It outlines various synthesis methods for nanoparticles, including physical, chemical, and biological approaches, and describes the advantages and disadvantages of different manufacturing techniques for nanofluids. Additionally, the impact of surfactants on dispersion stability and the effects of nanoparticles on thermal conductivity and viscosity in convective heat transfer applications are examined.

![References

[1] Z. Narankhishig, J. Ham, H. Lee, H. Cho, Convective heat transfer characteristics of nanofluids including the magnetic

effect on heat transfer enhancement - a review, Appl Therm Eng. 193 (2021) 116987.

https://doi.org/10.1016/J.APPLTHERMALENG.2021.116987.

[2] H. Younes, M. Mao, S.M. Sohel Murshed, D. Lou, H. Hong, G.P. Peterson, Nanofluids: Key parameters to enhance thermal

conductivity and its applications, Appl Therm Eng. 207 (2022) 118202.

https://doi.org/10.1016/J.APPLTHERMALENG.2022.118202.

[3] S. Choi, J. Eastman, Enhancing thermal conductivity of fluids with nanoparticles, 1995. (n.d.).

https://www.osti.gov/biblio/196525 (accessed June 19, 2023).

[4] N. Pantidos, L.E. Horsfall, Biological synthesis of metallic nanoparticles by bacteria, fungi and plants, J Nanomed

Nanotechnol. 5 (2014) 1.

[5] R.L. Hamilton, Thermal conductivity of heterogeneous two-component systems, Industrial and Engineering Chemistry

Fundamentals. 1 (1962) 187–191. https://doi.org/10.1021/I160003A005.

[6] S.M.S. Murshed, K.C. Leong, C. Yang, Enhanced thermal conductivity of TiO2 - Water based nanofluids, International

Journal of Thermal Sciences. 44 (2005) 367–373. https://doi.org/10.1016/j.ijthermalsci.2004.12.005.

[7] J.Y. Jung, E.S. Kim, Y.T. Kang, Stabilizer effect on CHF and boiling heat transfer coefficient of alumina/water nanofluids, Int

J Heat Mass Transf. 55 (2012) 1941–1946. https://doi.org/10.1016/j.ijheatmasstransfer.2011.11.049.

[8] X. Li, Y. Chen, S. Mo, L. Jia, X. Shao, Effect of surface modification on the stability and thermal conductivity of water-based

SiO2-coated graphene nanofluid, Thermochim Acta. 595 (2014) 6–10. https://doi.org/10.1016/j.tca.2014.09.006.](https://image.slidesharecdn.com/nano-240622202432-12a6f4b5/75/NANO-fluids-brief-introduction-seminar-pdf-22-2048.jpg)

![References

[9] H.E. Patel, K.B. Anoop, T. Sundararajan, S.K. Das, A micro-convection model for thermal conductivity of nanofluids, in:

International Heat Transfer Conference 13, Begel House Inc., 2006.

[10] . Hojjat, S.G. Etemad, R. Bagheri, J. Thibault, Convective heat transfer of nonNewtonian nanofluids through a uniformly

heated circular tube, Int. J. Therm. Sci. 50 (4) (2011) 525–531.

[11] . A. Amrollahi, A.M. Rashidi, R. Lotfi, M.E. Meibodi, K. Kashefi, Convection heat transfer of functionalized MWNT in

aqueous fluids in laminar and turbulent flow at entrance region, Int. Commun. Heat Mass Transf. 37 (2010) 717–723.

[12] .W. Yu, D.M. France, S. Smith, D. Singh, E.V. Timofeeva, J.L. Routbort, Heat transfer to a silicon carbide/water nanofluid,

Int. J. Heat Mass Transf. 52 (2009) 2272–2281.

[13] M. Hojjat, S.G. Etemad, R. Bagheri, J. Thibault, Convective heat transfer of nonNewtonian nanofluids through a

uniformly heated circular tube, Int. J. Therm. Sci. 50 (4) (2011) 525–531.

[14] J.T. Cieslinski, P. Kozak, Experimental investigation of forced convection of water/EG-Al2O3 nanofluids inside horizontal

tube, E3S Web Conferences. 70 (2018) 1–5.](https://image.slidesharecdn.com/nano-240622202432-12a6f4b5/75/NANO-fluids-brief-introduction-seminar-pdf-23-2048.jpg)