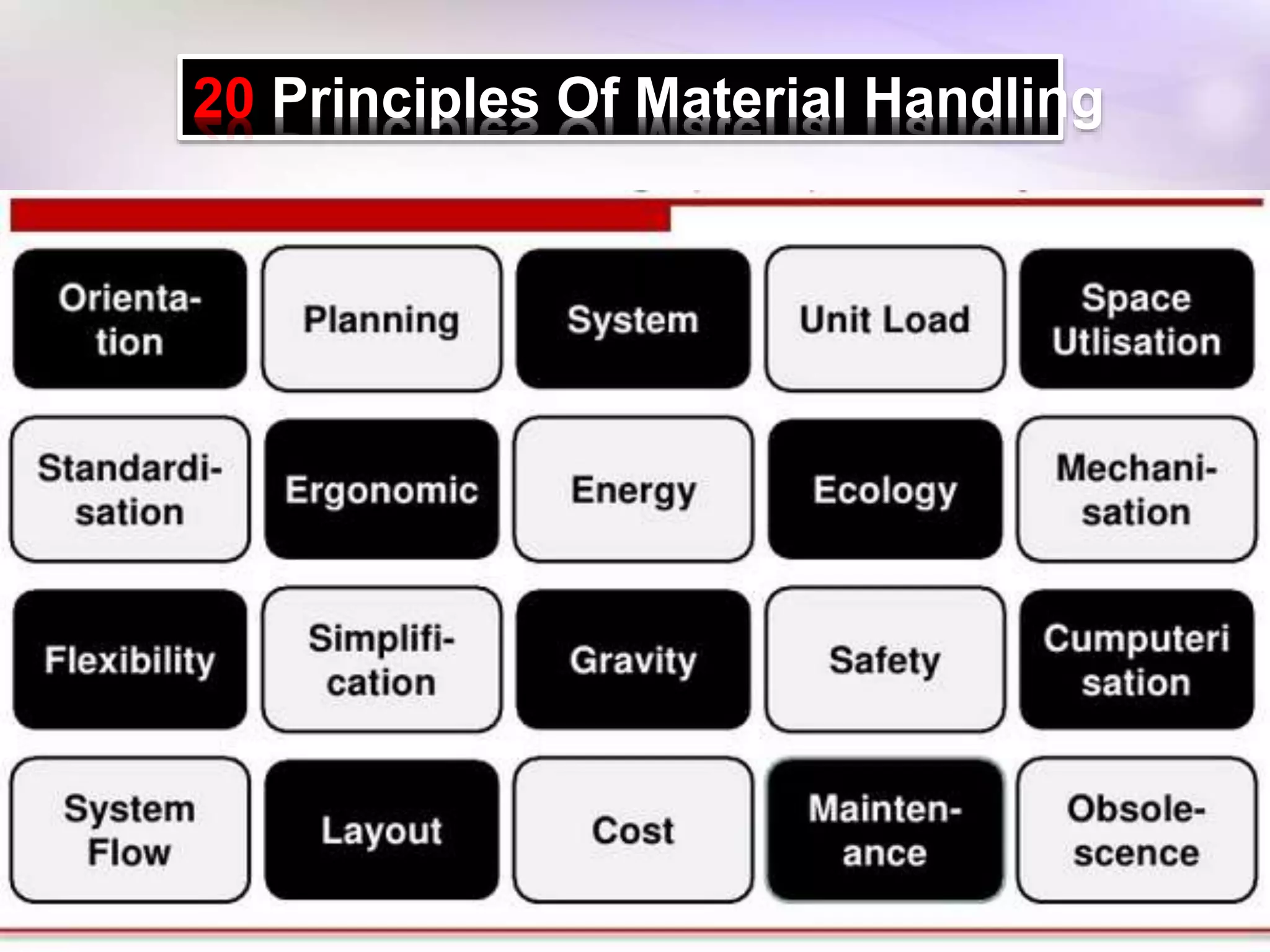

Maintenance and material handling are important for maximizing productivity and minimizing costs. There are different types of maintenance including corrective, scheduled, preventive, and predictive maintenance. Material handling aims to move materials efficiently through operations and accounts for a significant portion of manufacturing costs. Effective maintenance and material handling systems consider factors like minimizing distance, avoiding rehandling, and selecting appropriate container types and equipment.

![Material Handling is the function of moving the right material

to the right place at the right time, in the right amount, in right

sequence, and in the right condition to minimize production

cost.

The cost of MH estimates 20-25% of total manufacturing

labor cost in the United States [The Material Handling

Industry of America (MHIA)]](https://image.slidesharecdn.com/maintenanceandmaterialhandlingmethods1-140619161121-phpapp02/75/Maintenance-and-material-handling-methods-1-31-2048.jpg)