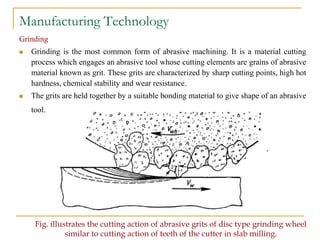

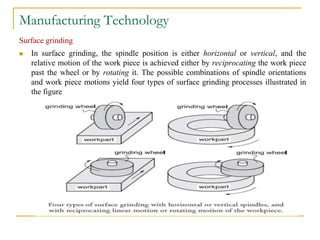

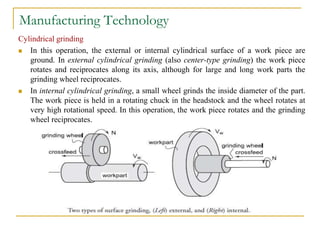

Abrasive machining processes remove material from a workpiece using small abrasive particles. There are two categories: bonded abrasive processes where particles are bonded together and transferred to the workpiece via a wheel; and loose abrasive processes where particles are applied without bonding and forced into the workpiece. Grinding is the most common abrasive process and involves abrasive grains held in a tool to cut via sharp points. Grinding can be performed on surfaces, cylinders internally or externally, and without centers.