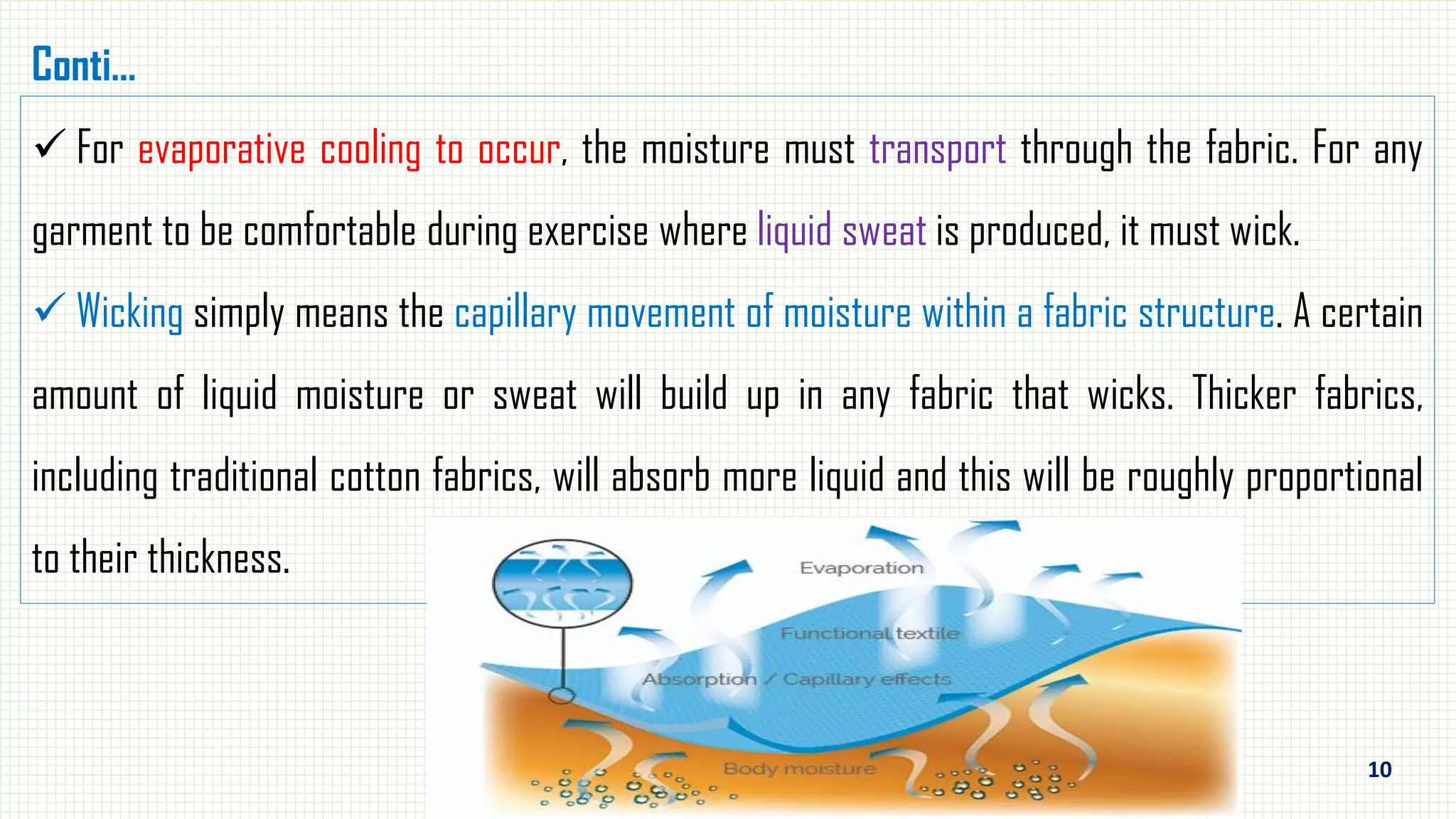

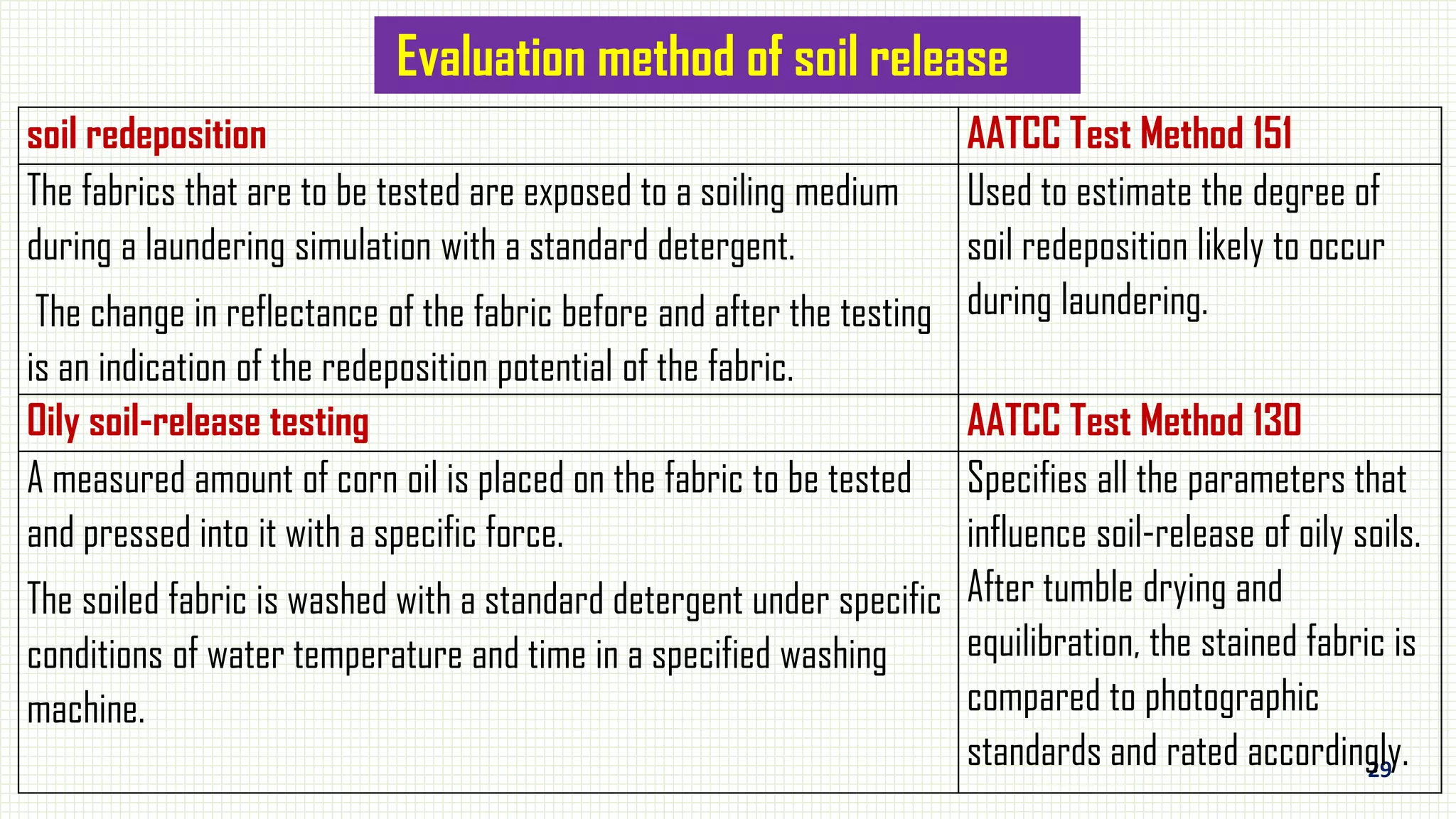

The document discusses moisture management and soil-release finishes for textiles, emphasizing their importance in enhancing comfort during wear by effectively transporting moisture and facilitating soil removal. It covers the mechanisms, chemistries, evaluation methods, and applications of these finishes, highlighting the challenges and future developments in textile technology. The paper asserts that moisture management finishes improve thermal regulation and comfort while soil-release finishes enable easier cleaning of fabrics.