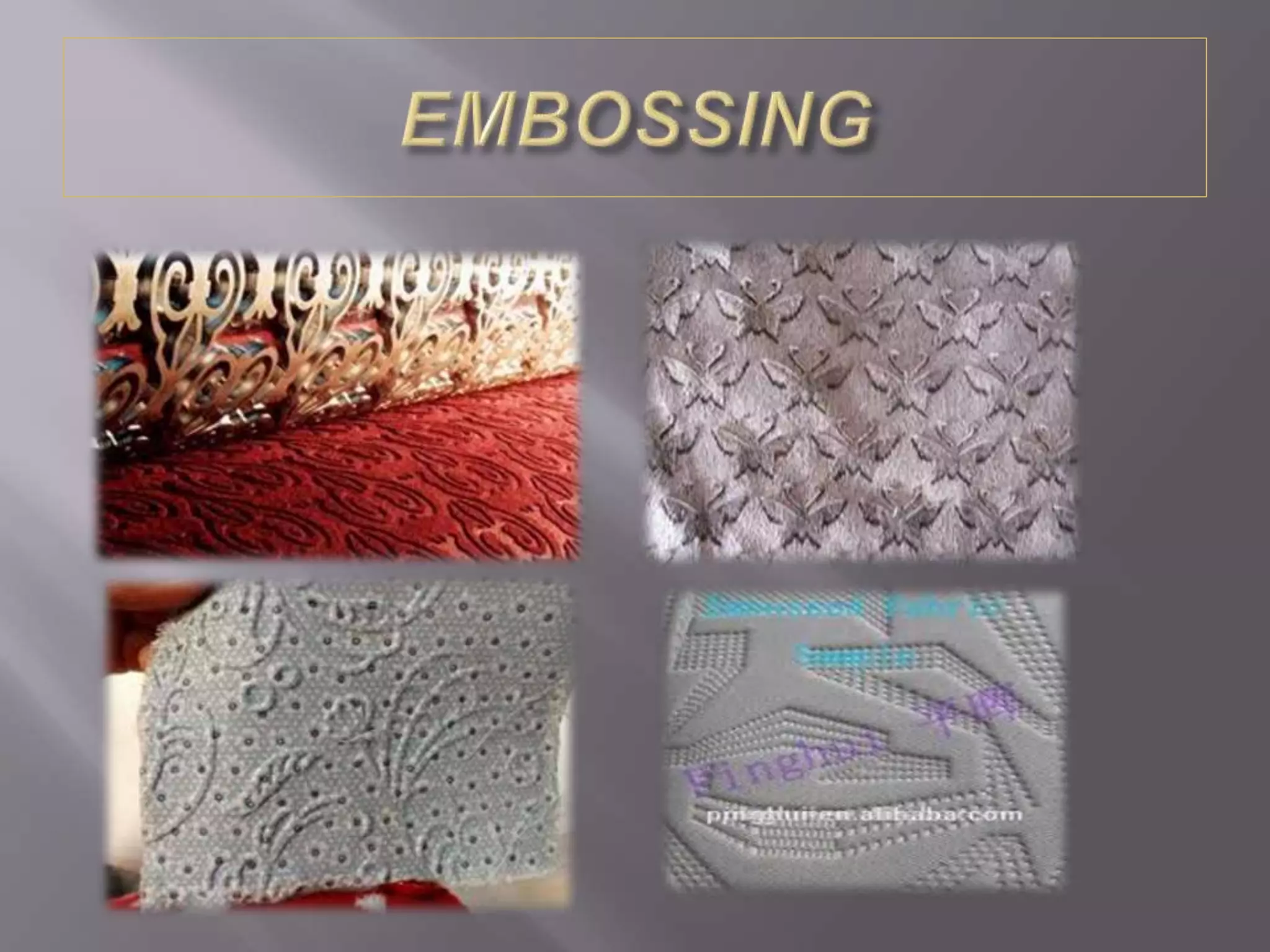

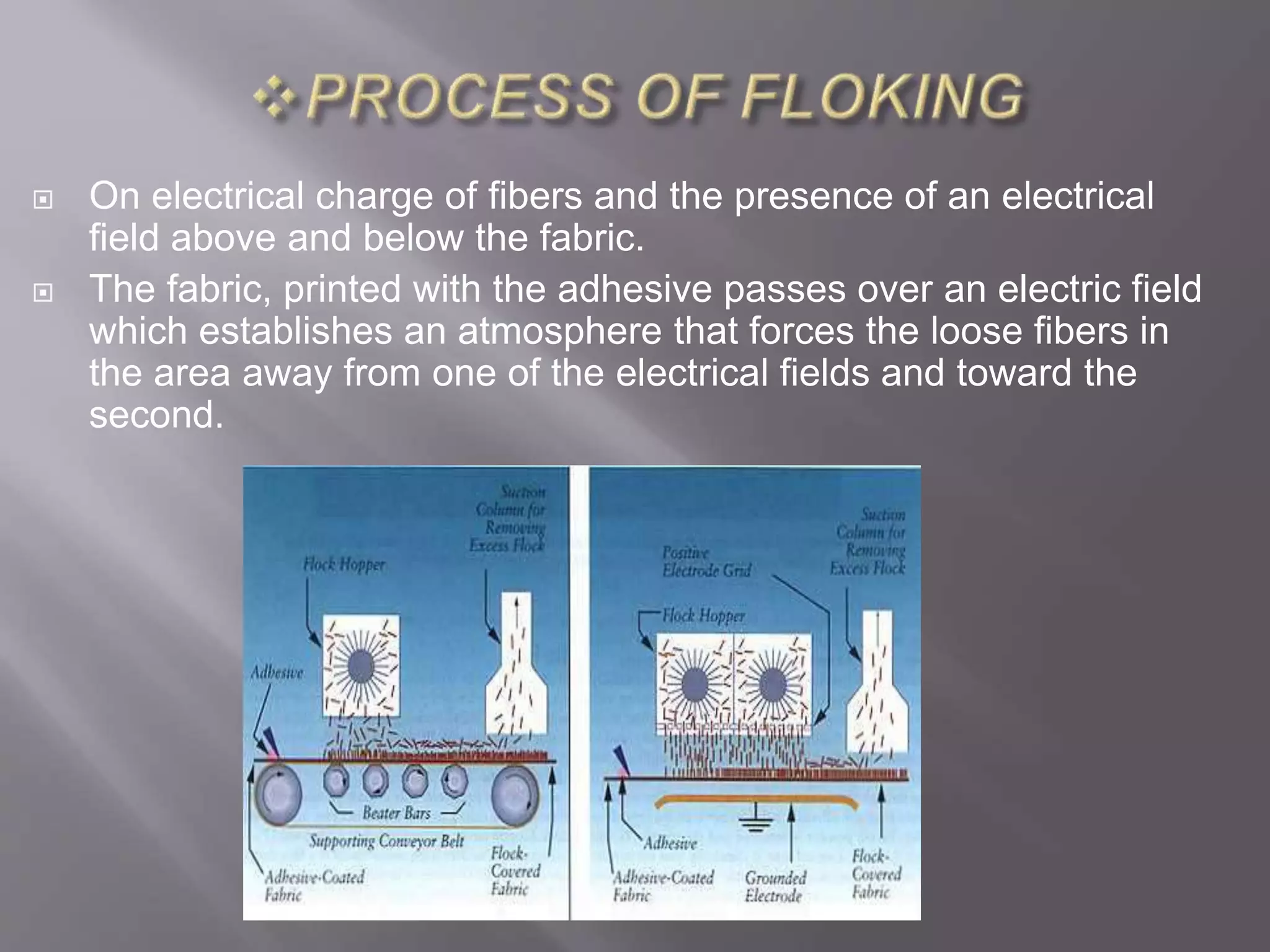

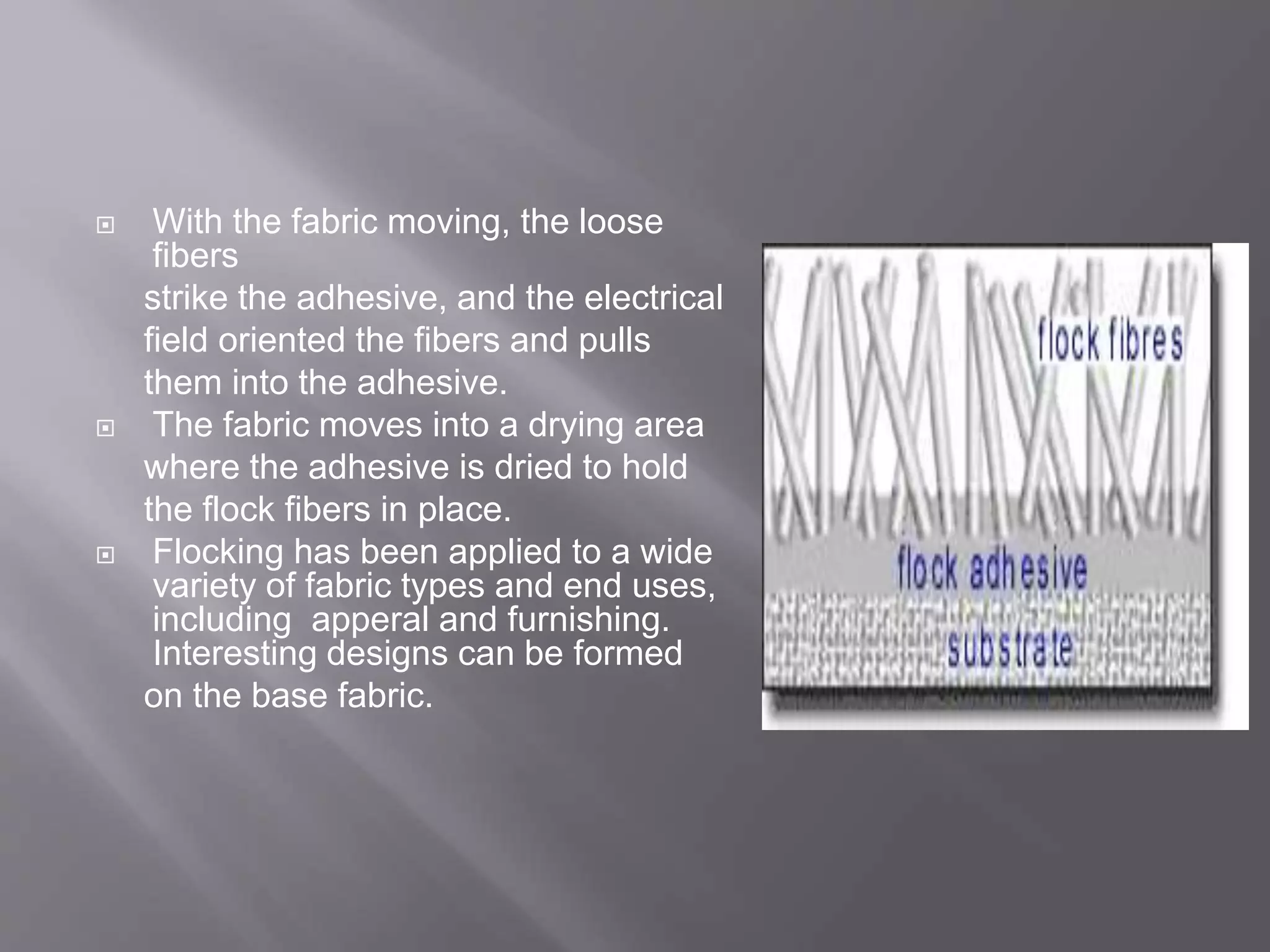

This document discusses various textile finishing processes. It describes embossing as using heated rollers to raise designs on fabric surfaces. Napping raises fibers on materials like cotton and rayon using needle rollers. Flocking adheres small fibers to fabrics to form designs. Softening finishes like anionic, cationic and nonionic conditioners are used to reduce static cling and soften textiles. Delustering and brightening chemicals are applied to synthetic fibers and fabrics to respectively reduce shine and increase the appearance of whiteness. Common brighteners are added to laundry detergents and paper.