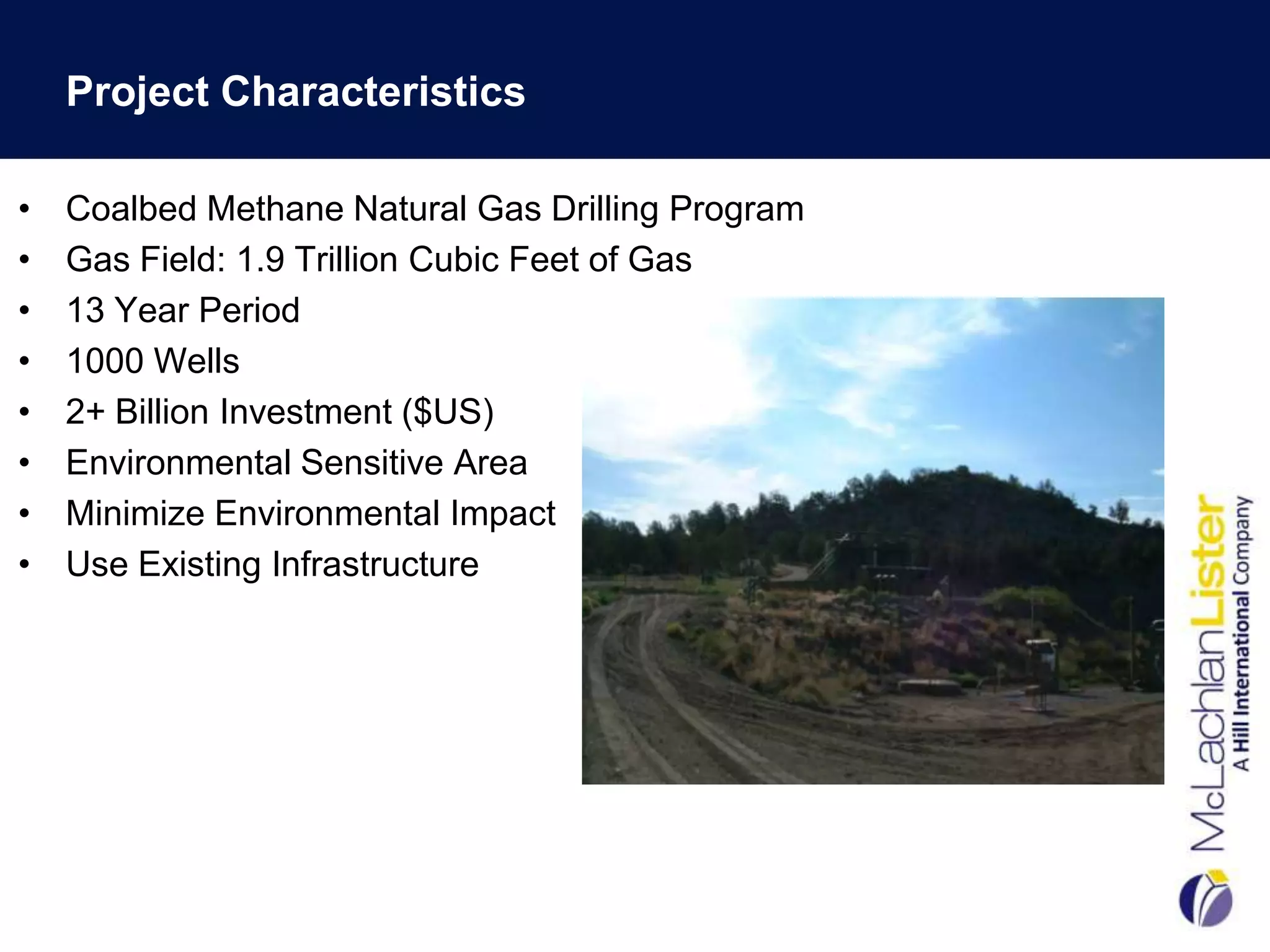

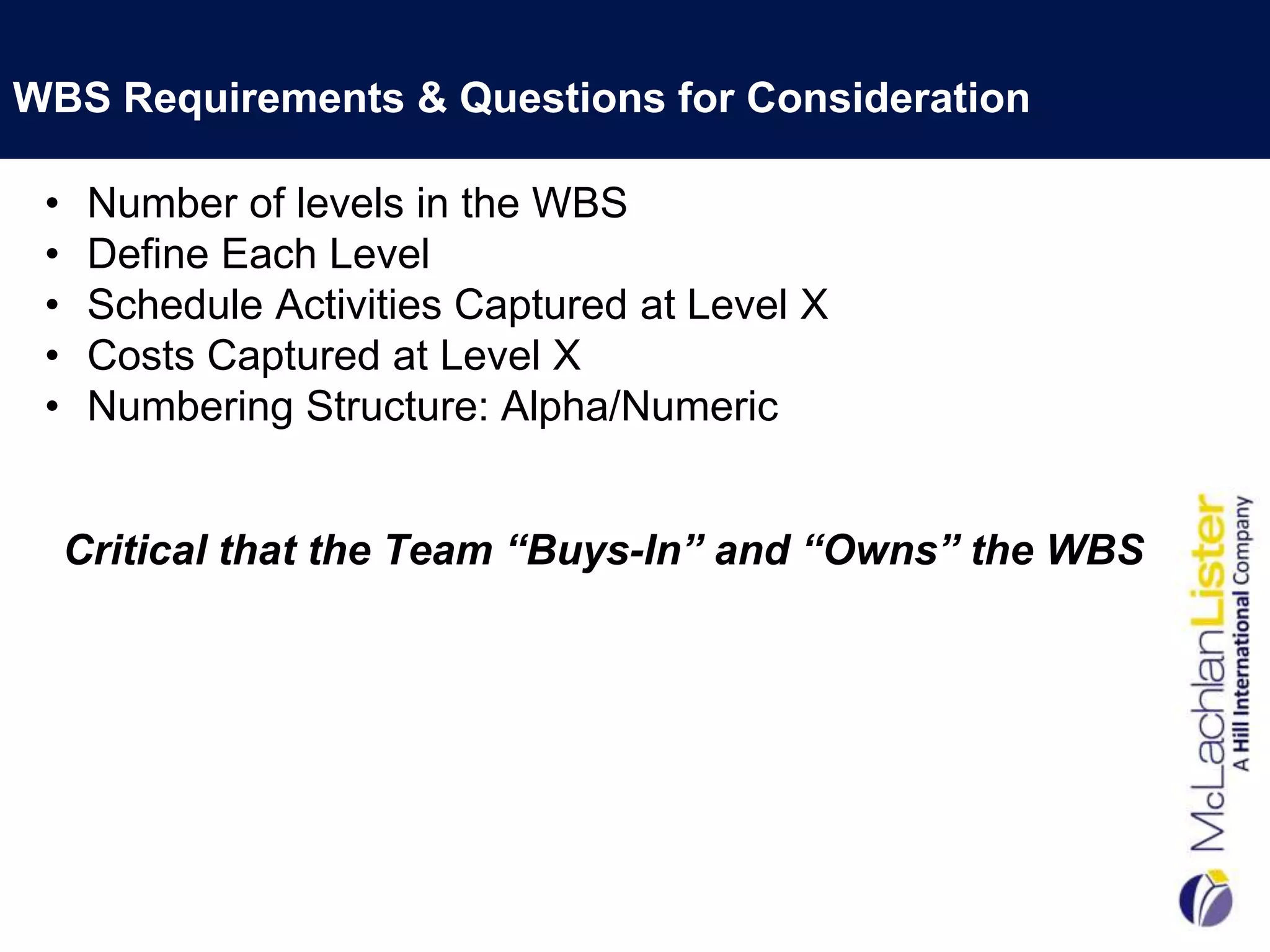

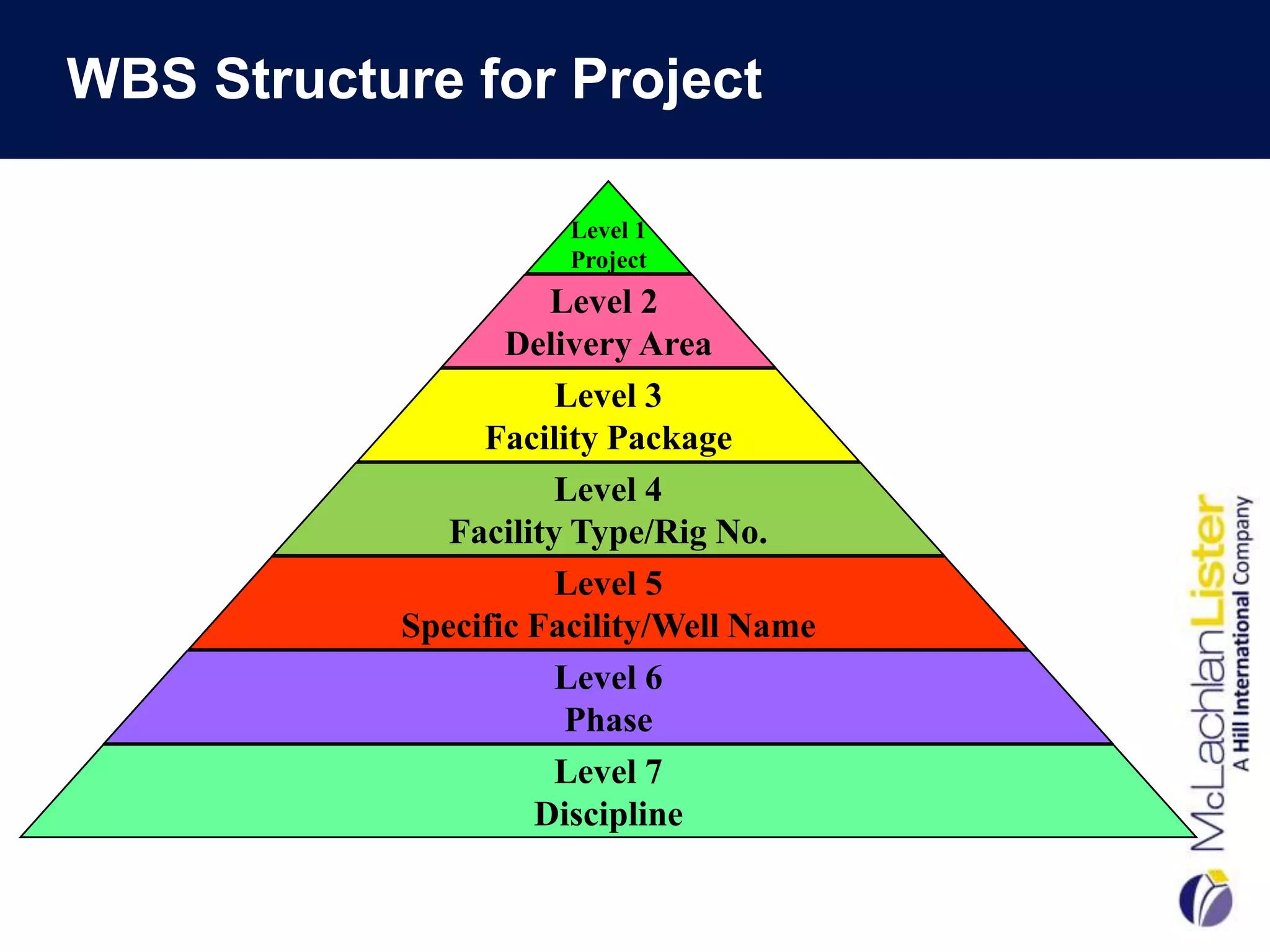

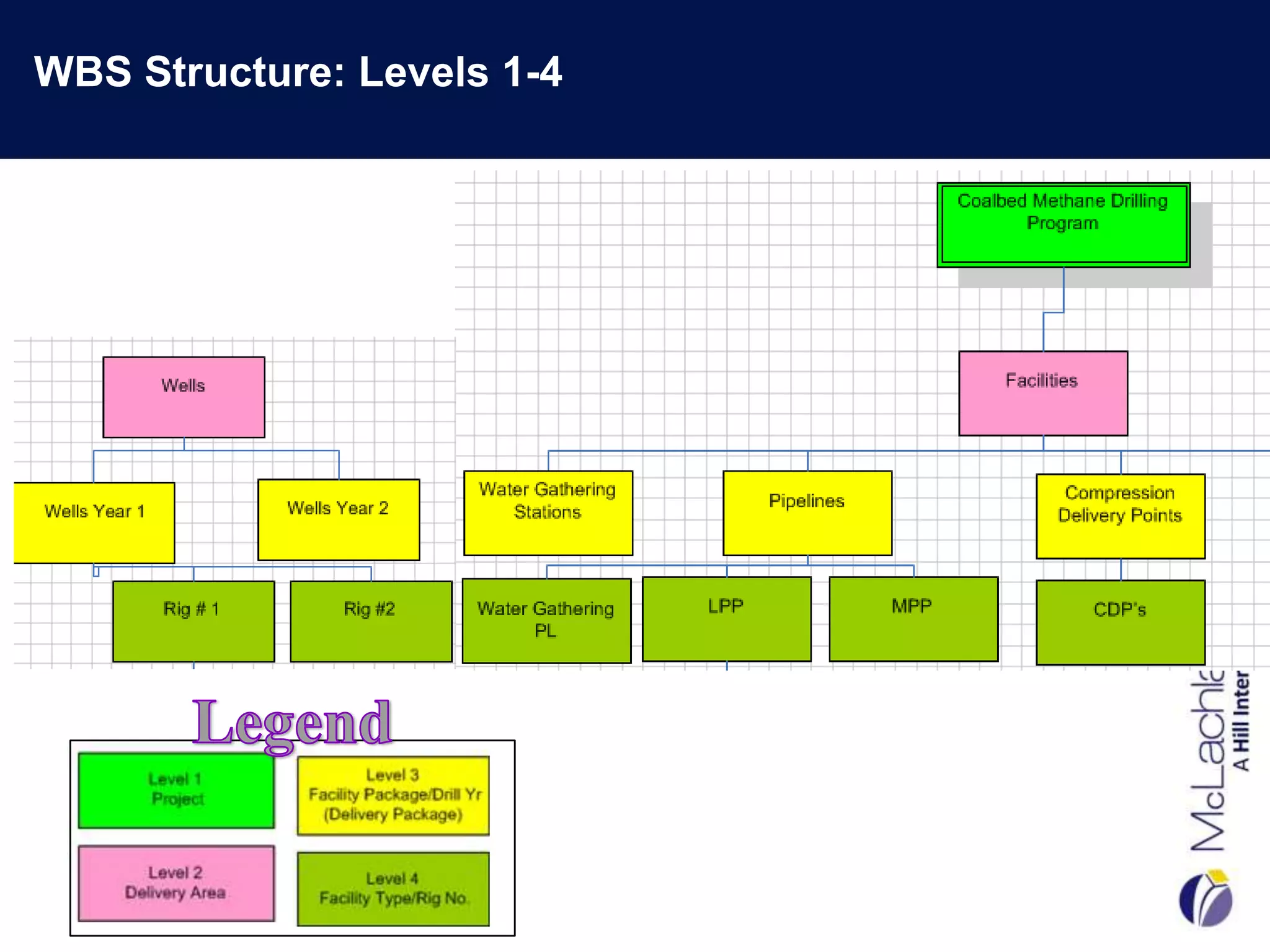

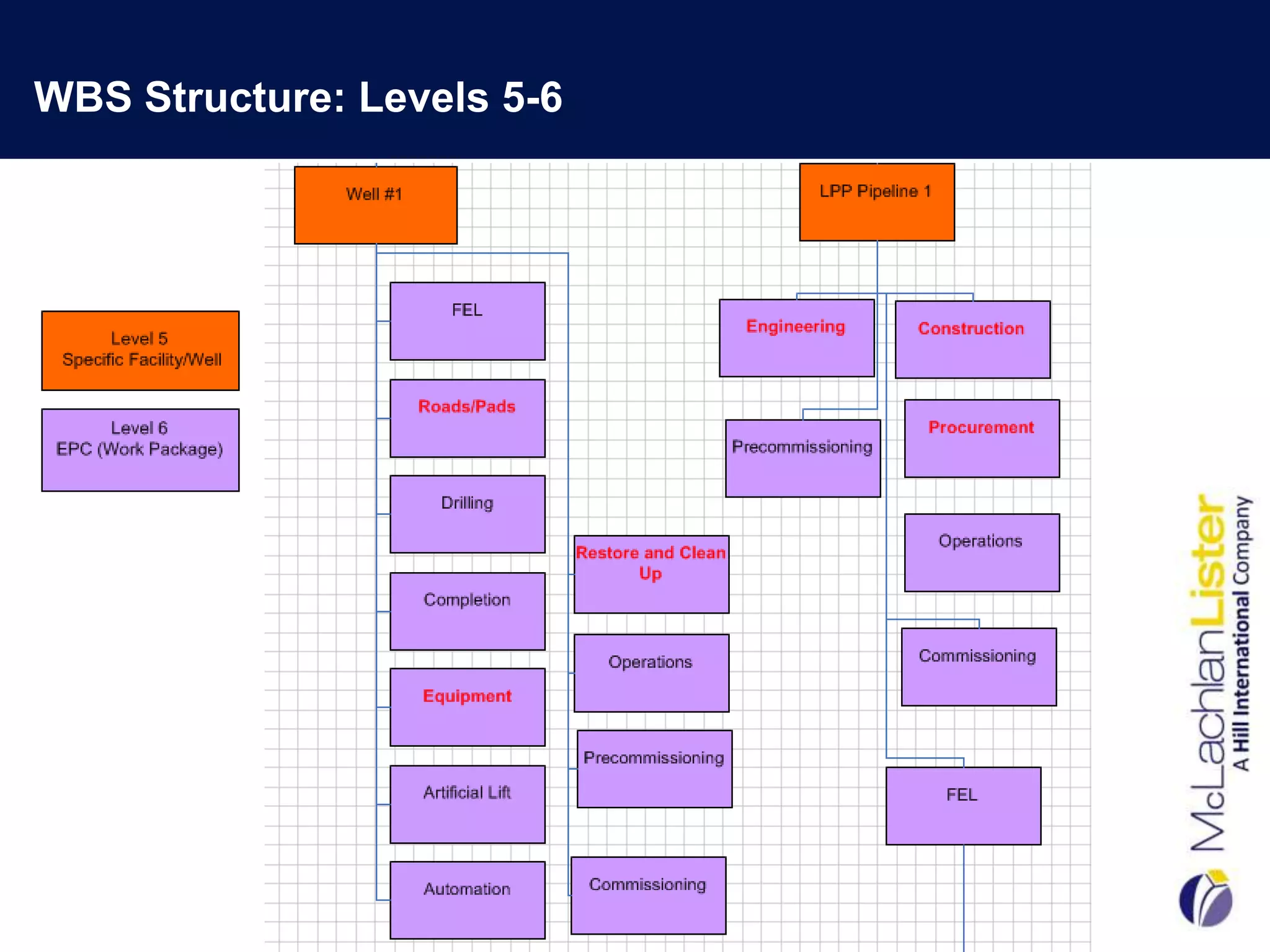

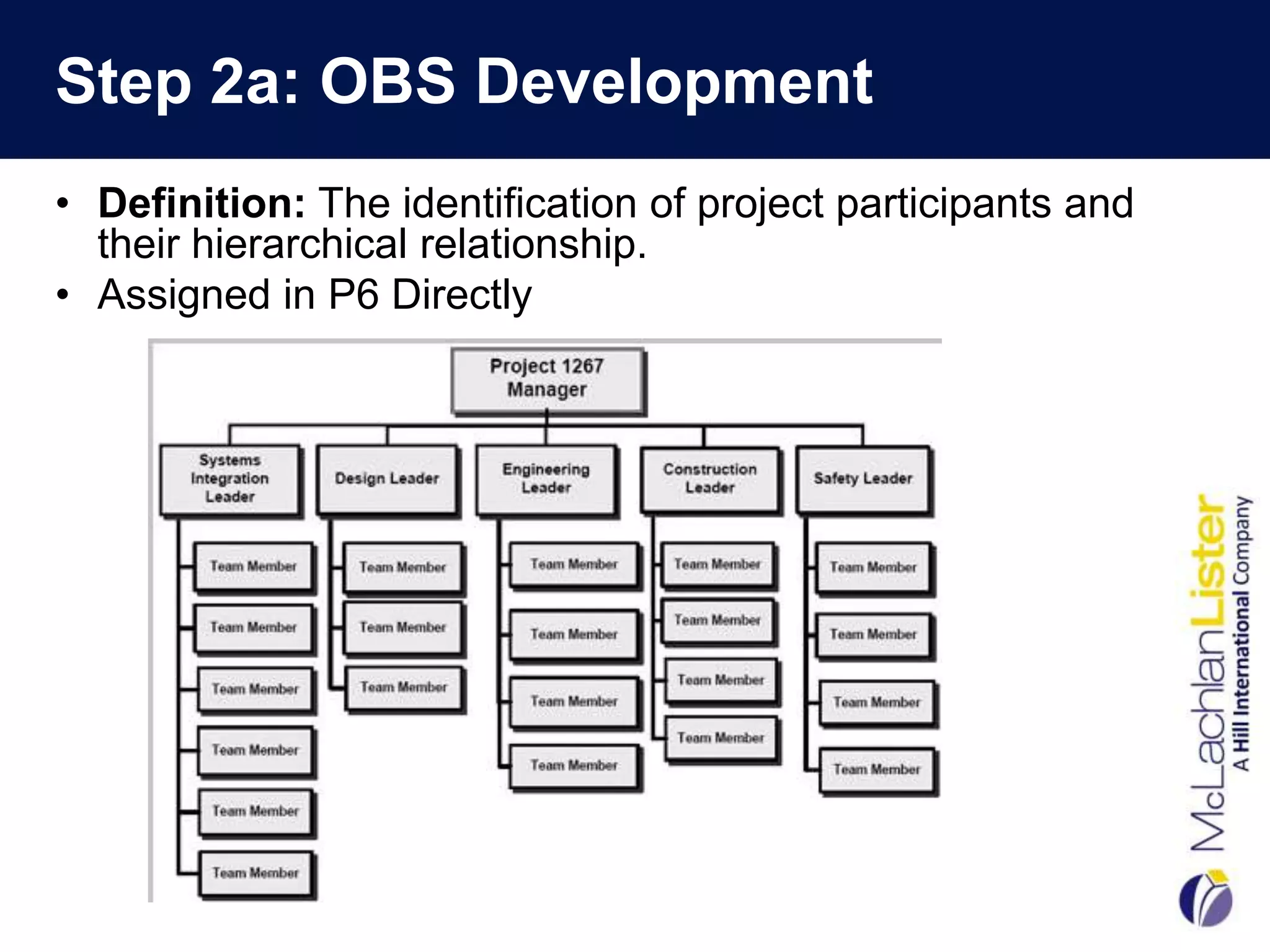

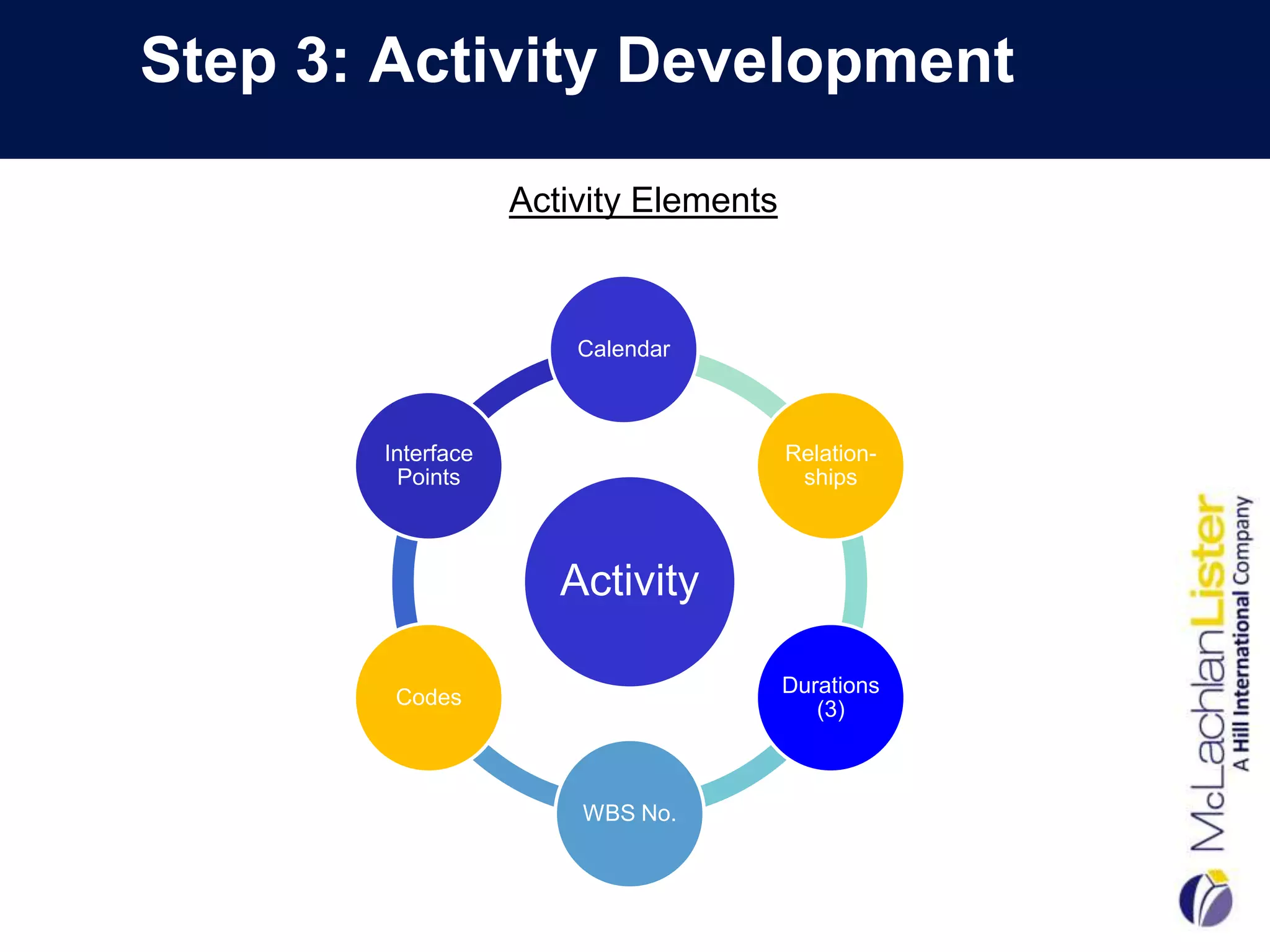

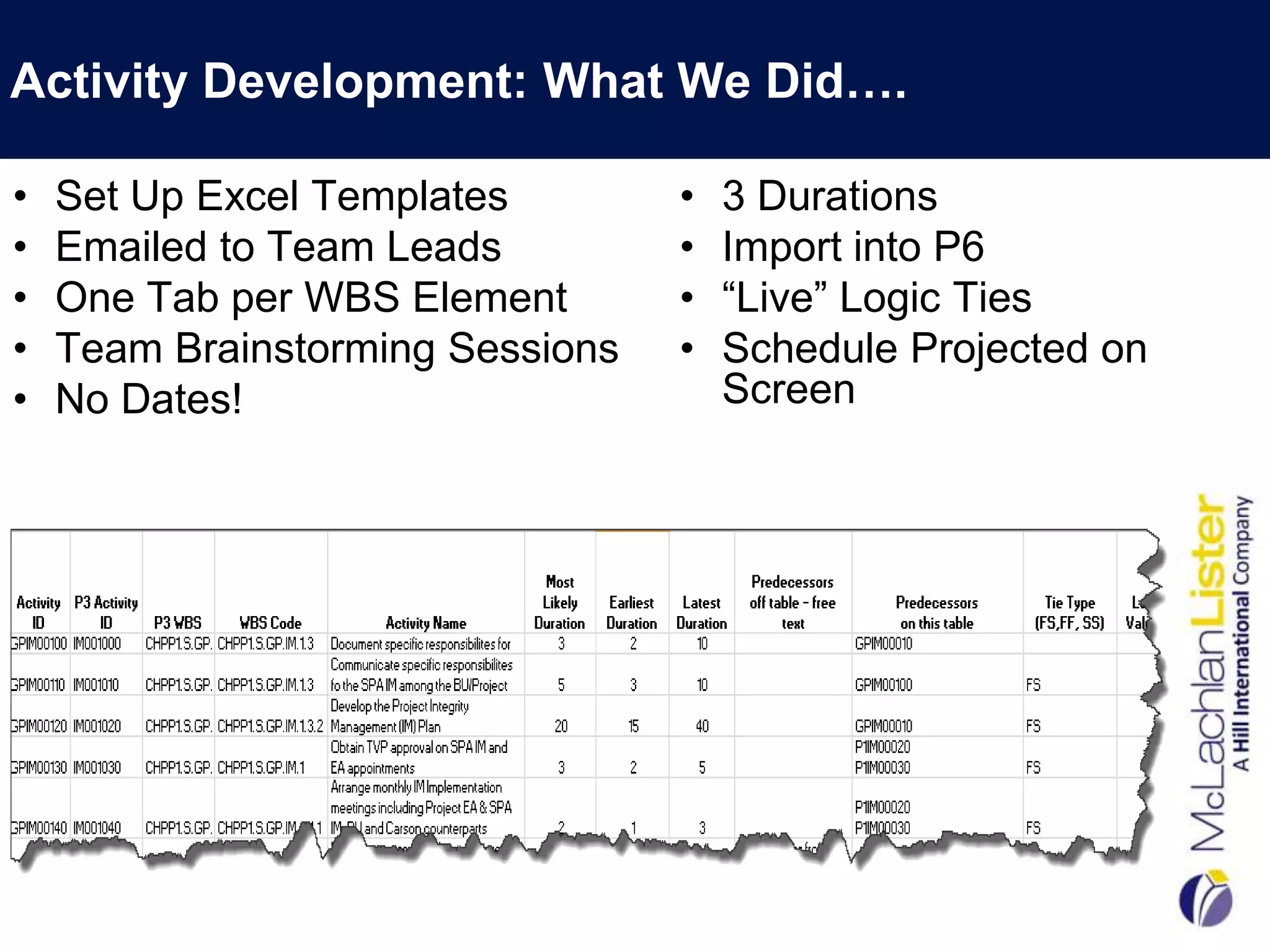

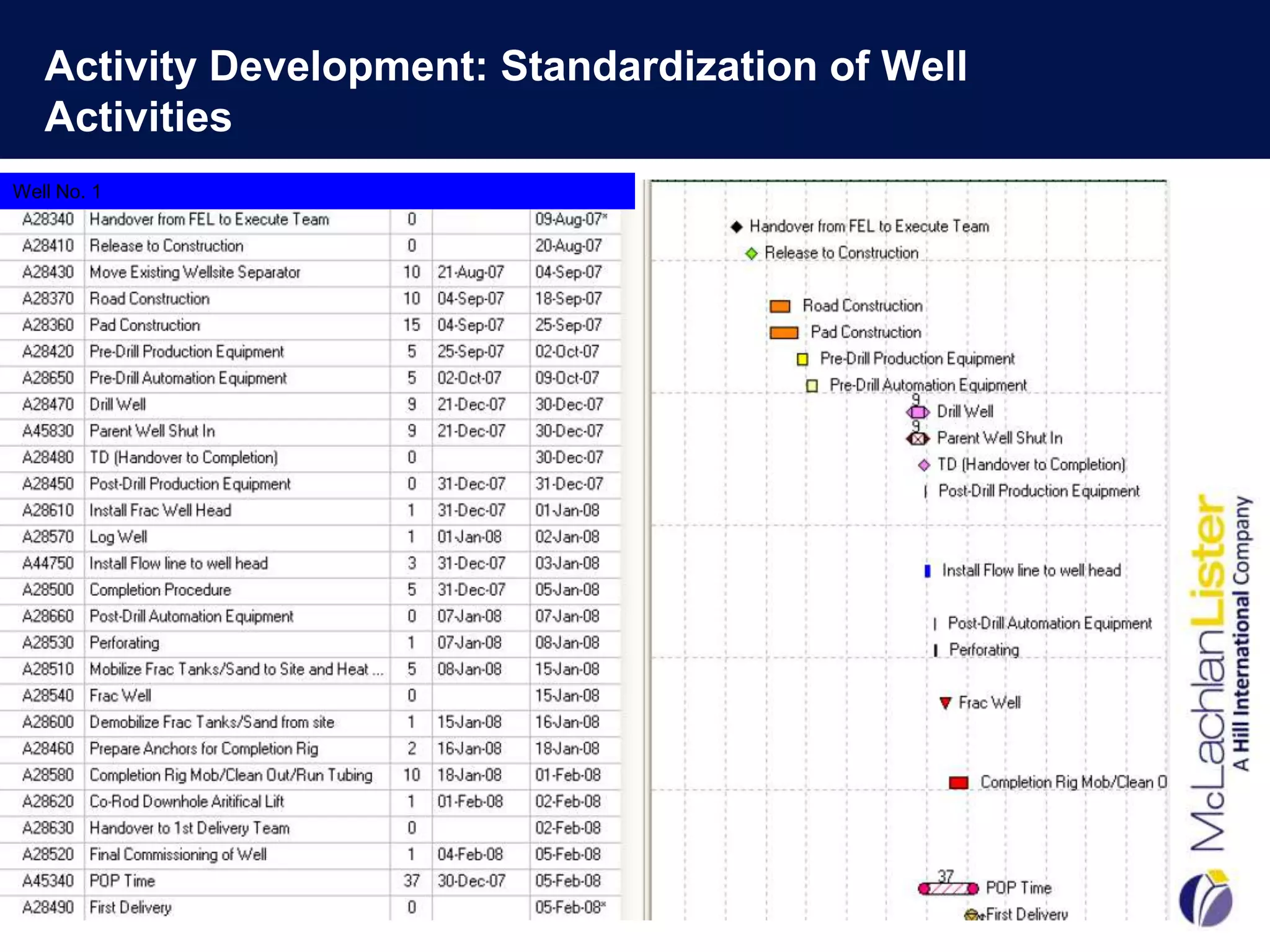

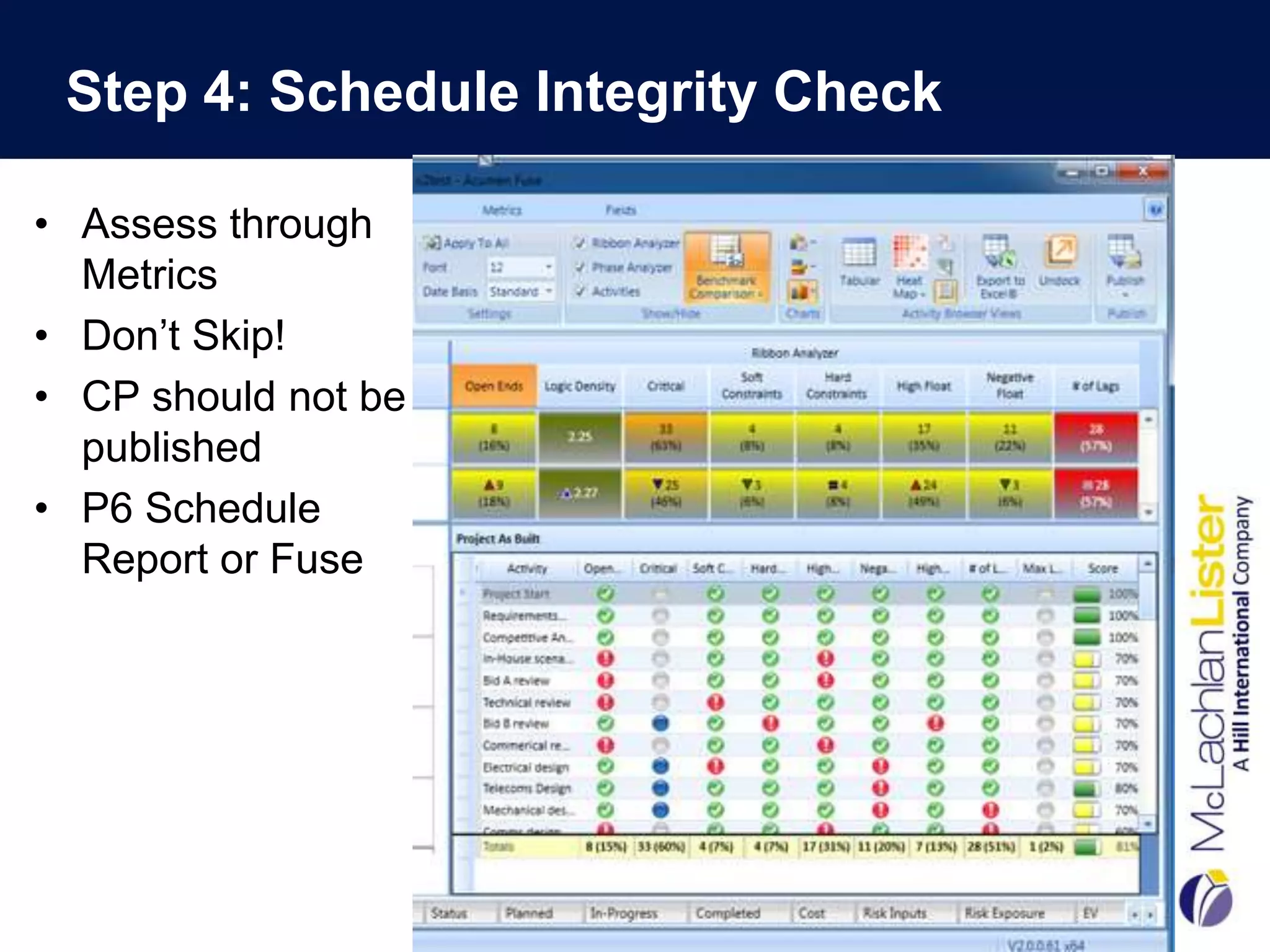

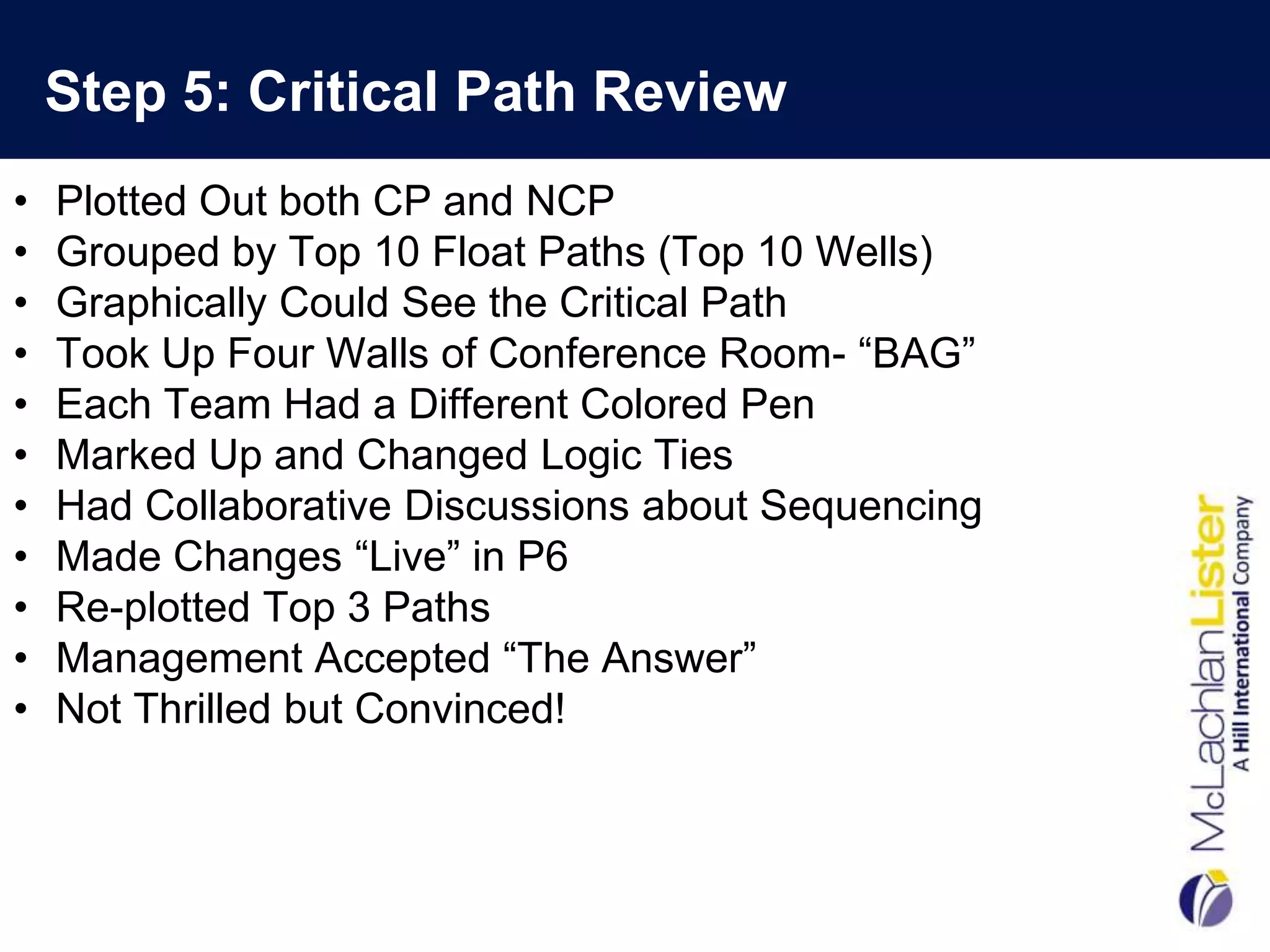

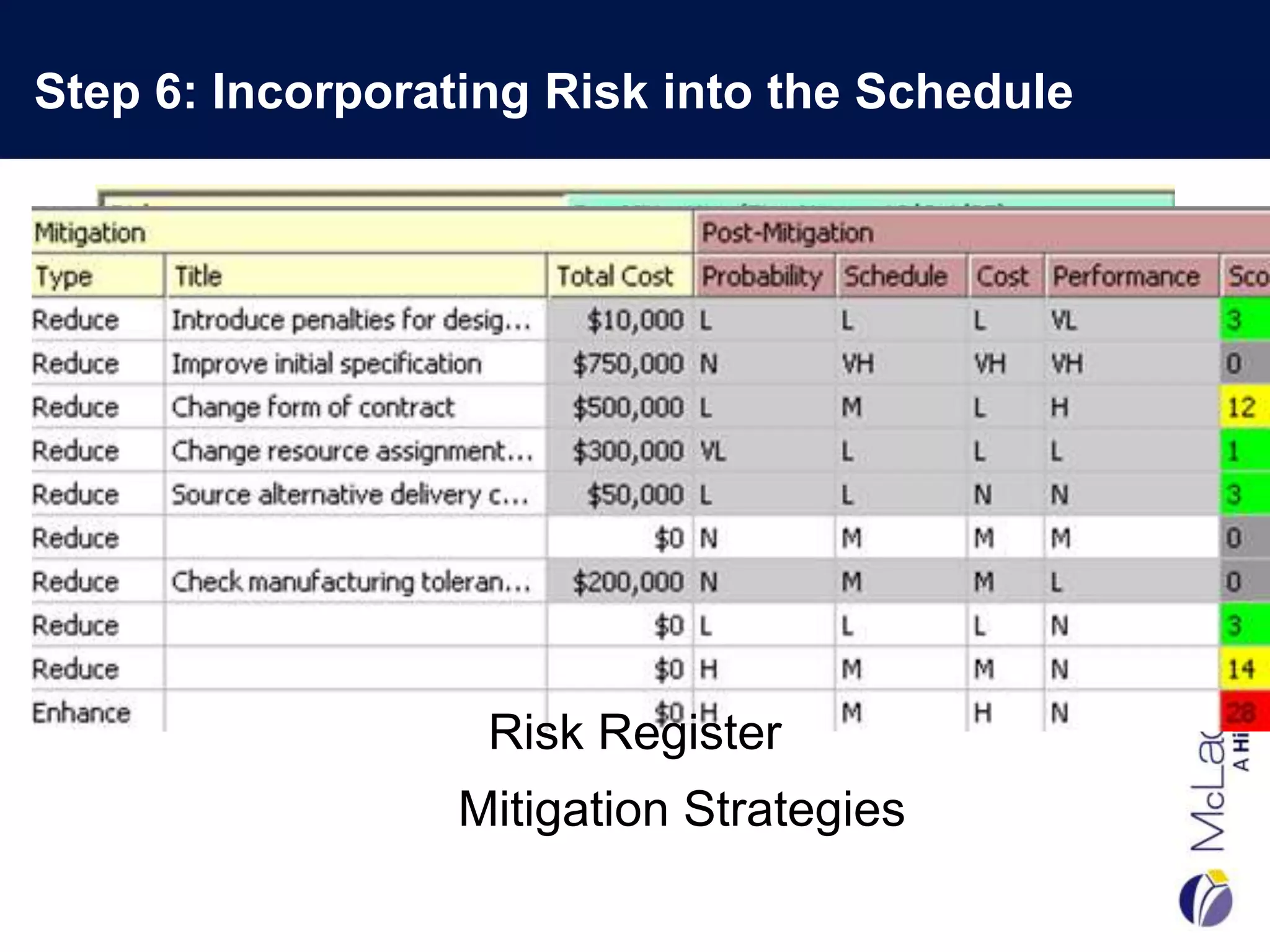

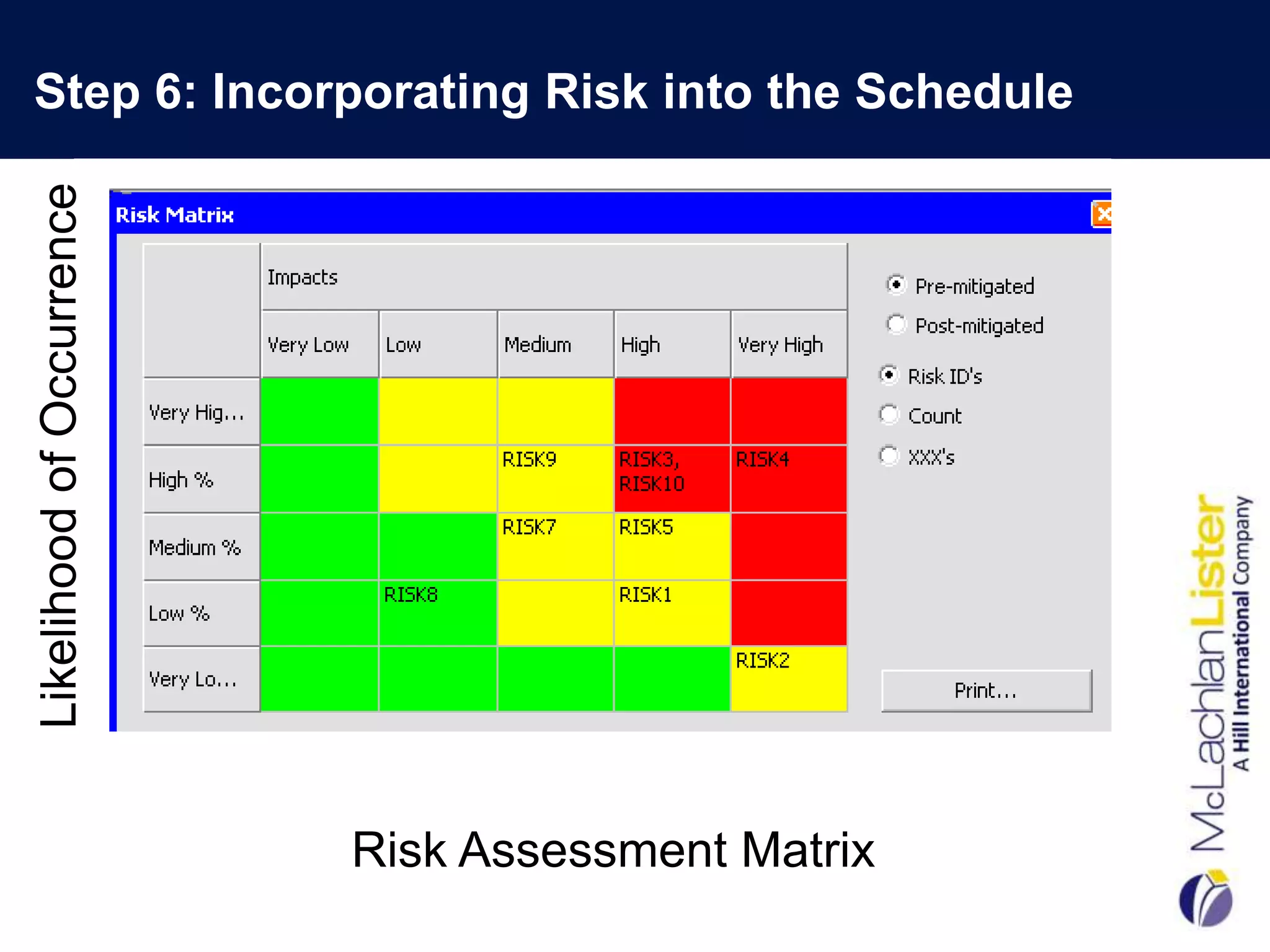

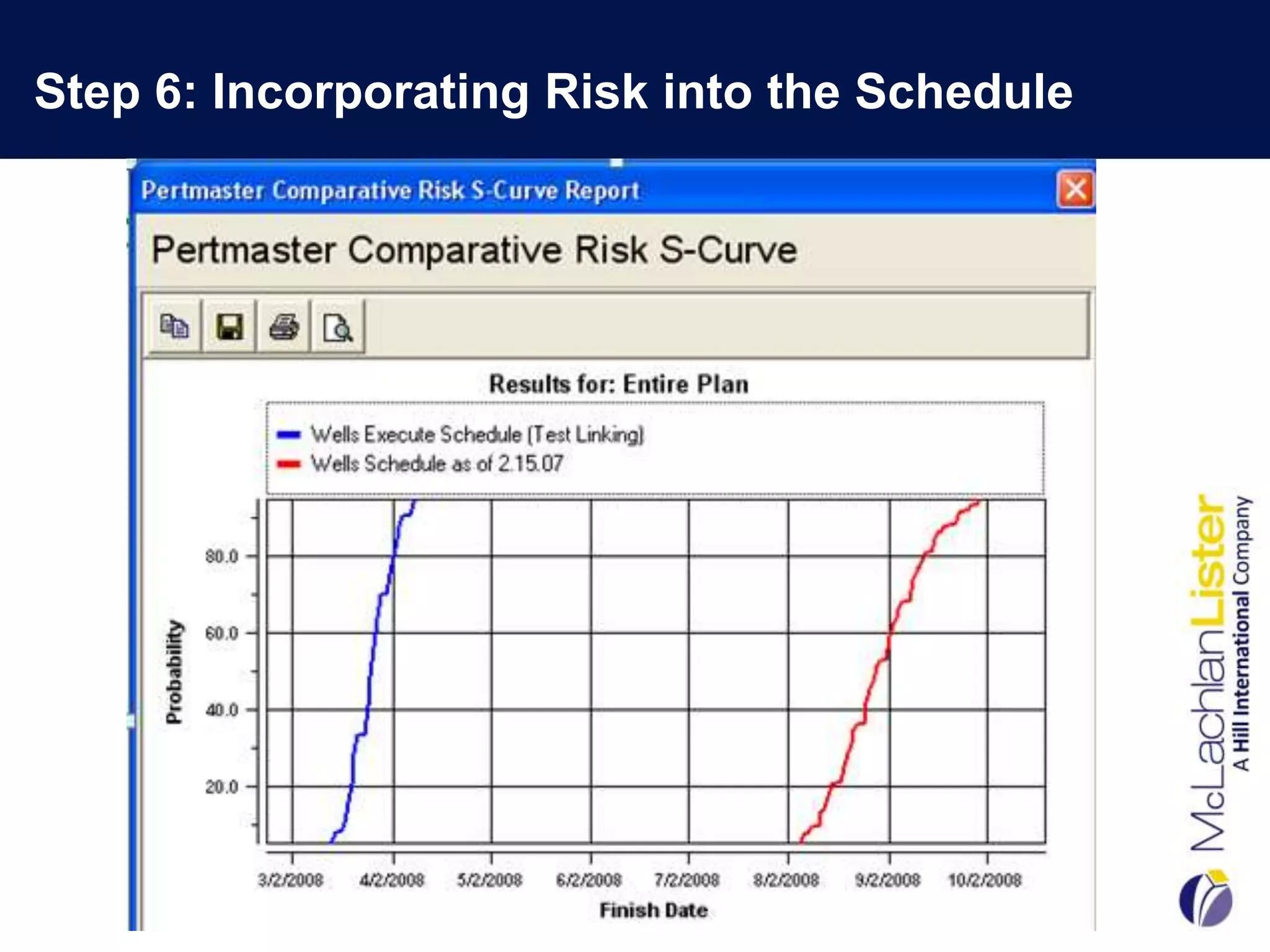

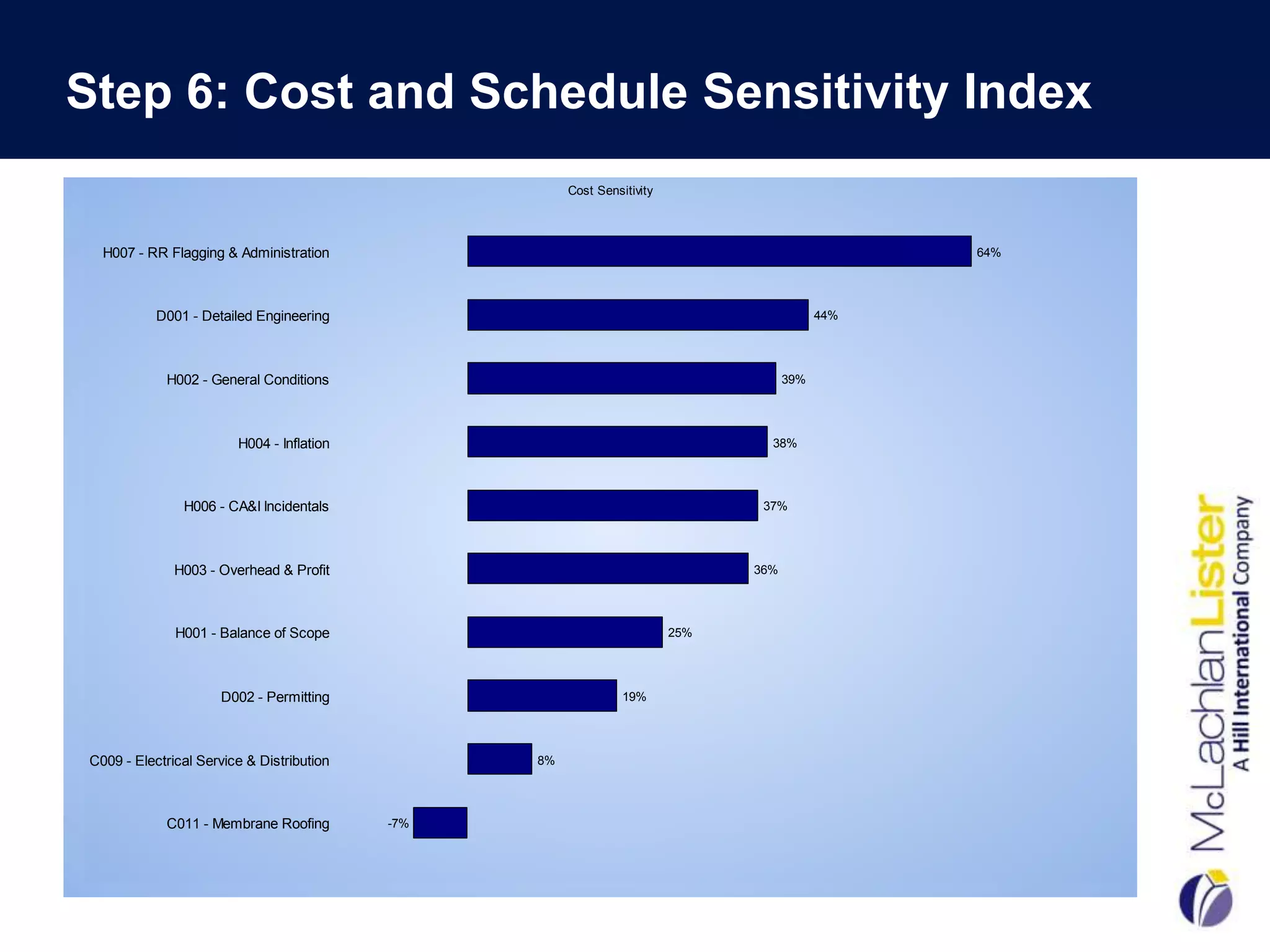

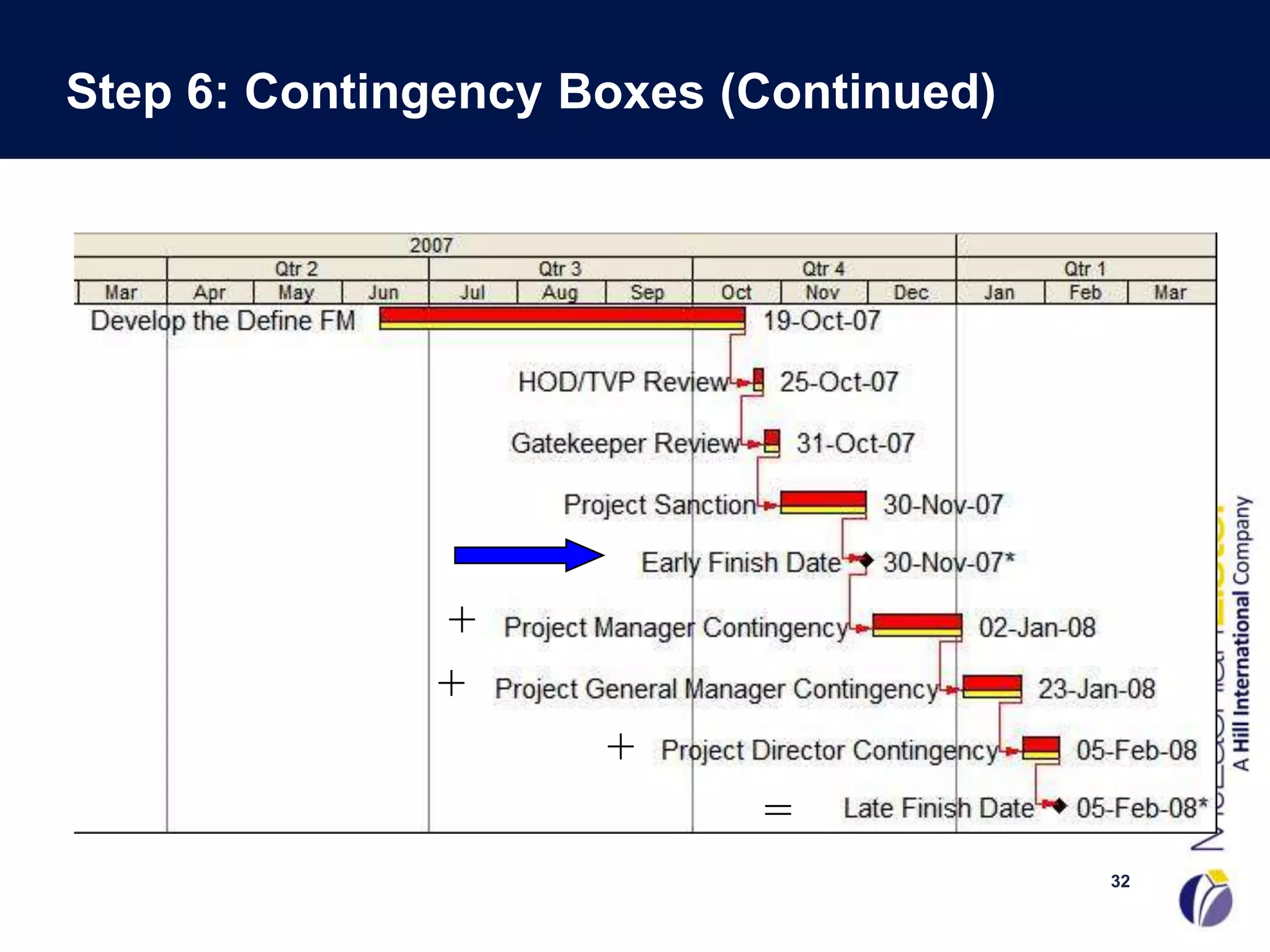

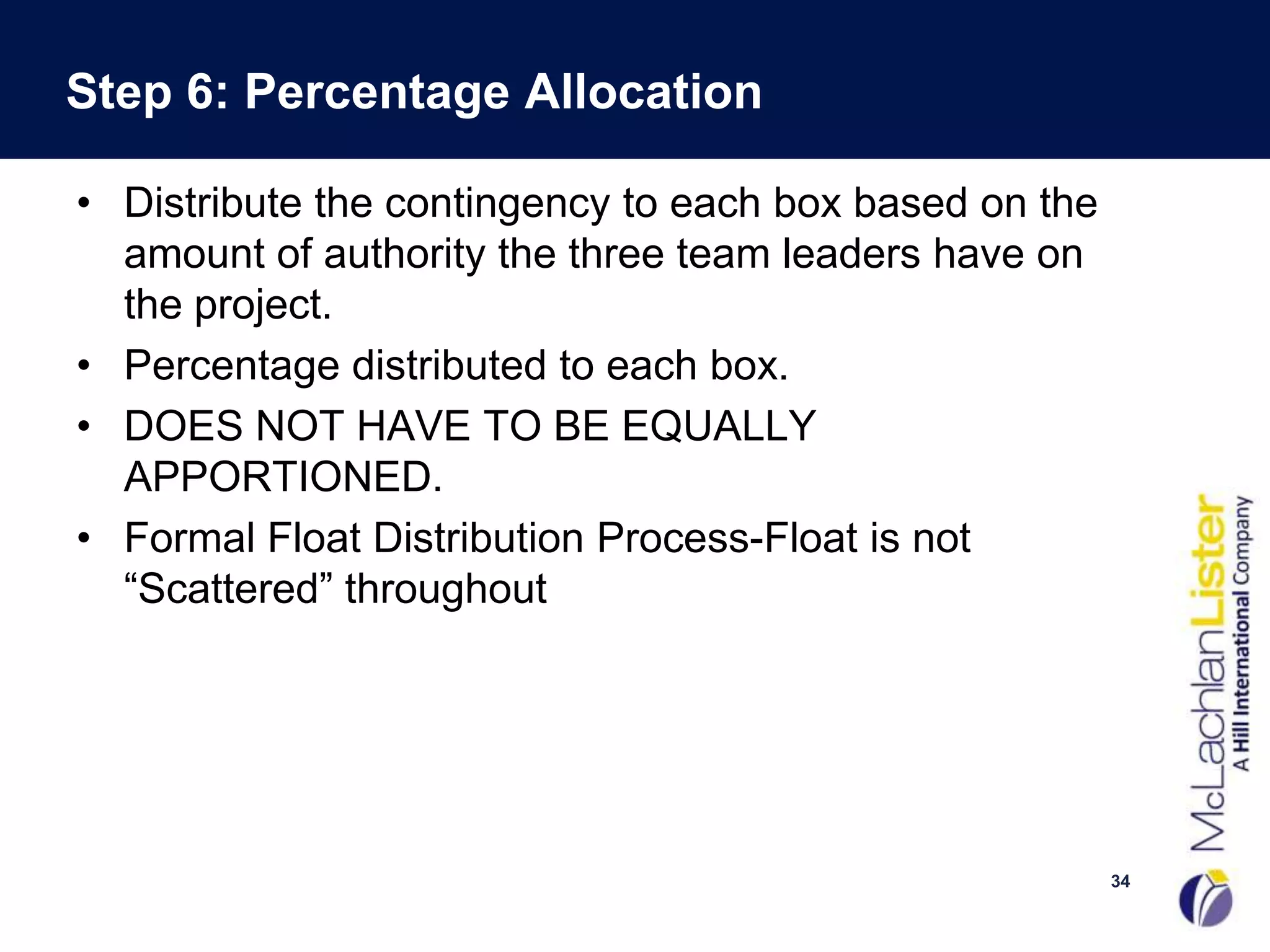

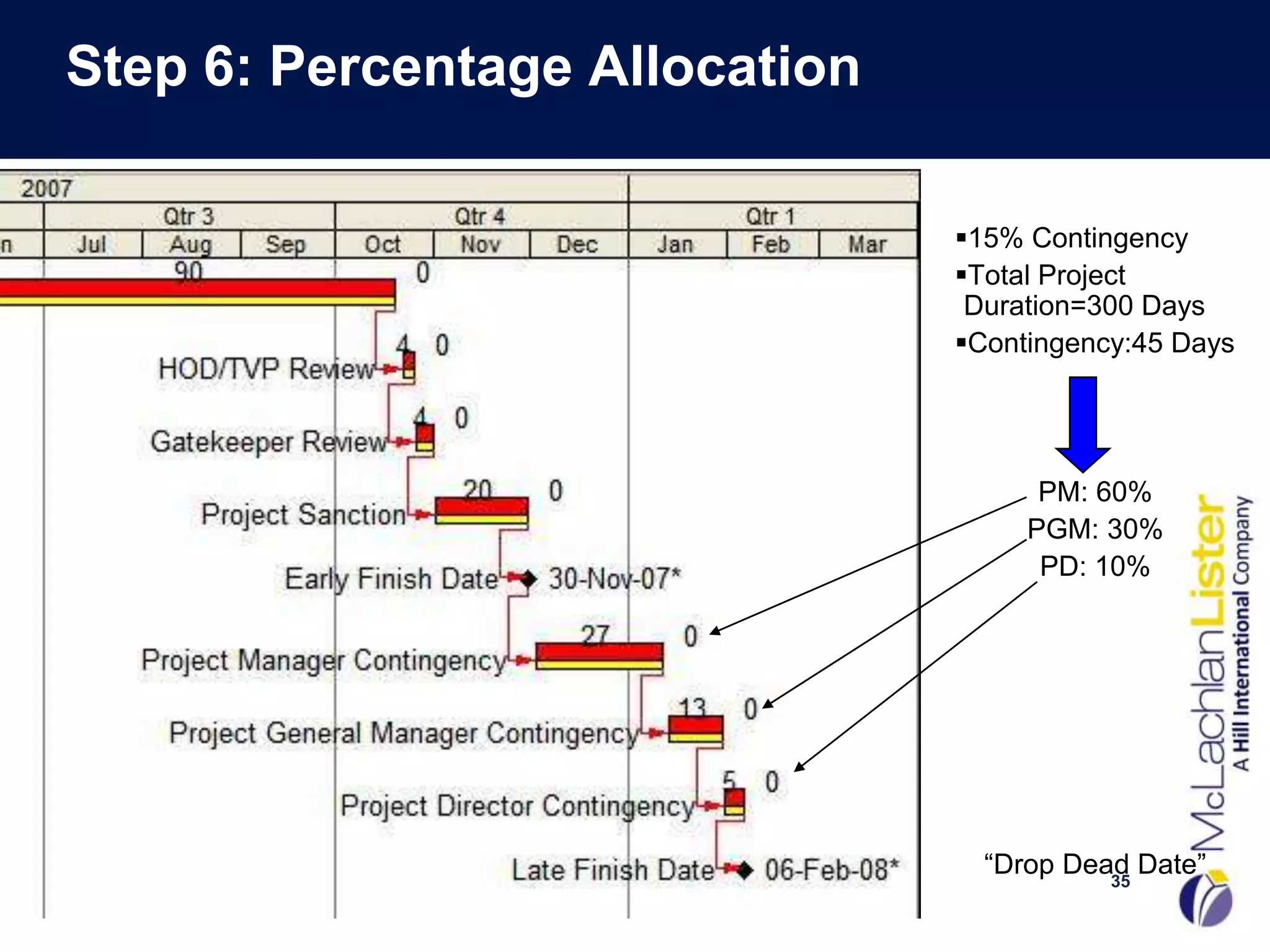

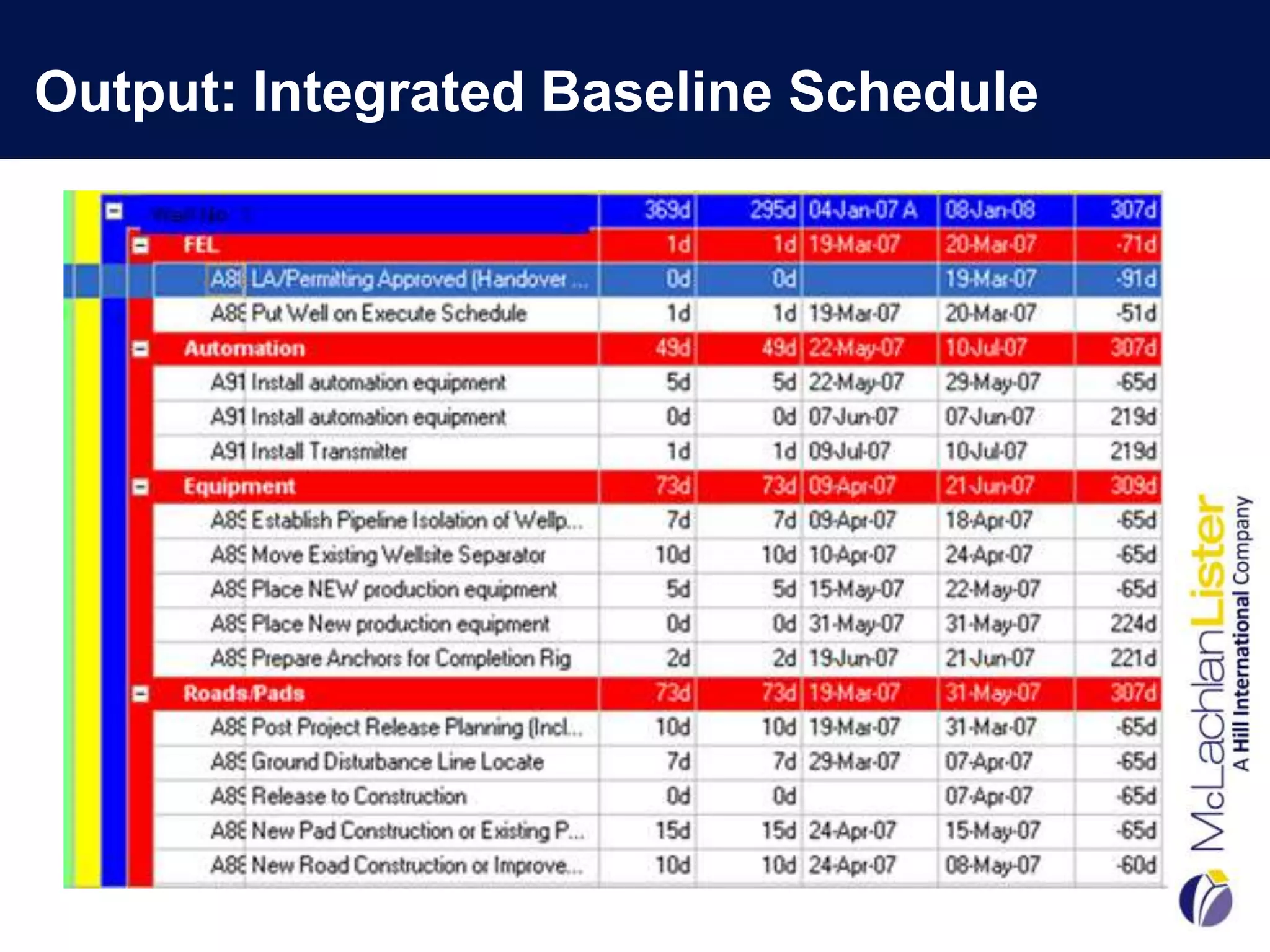

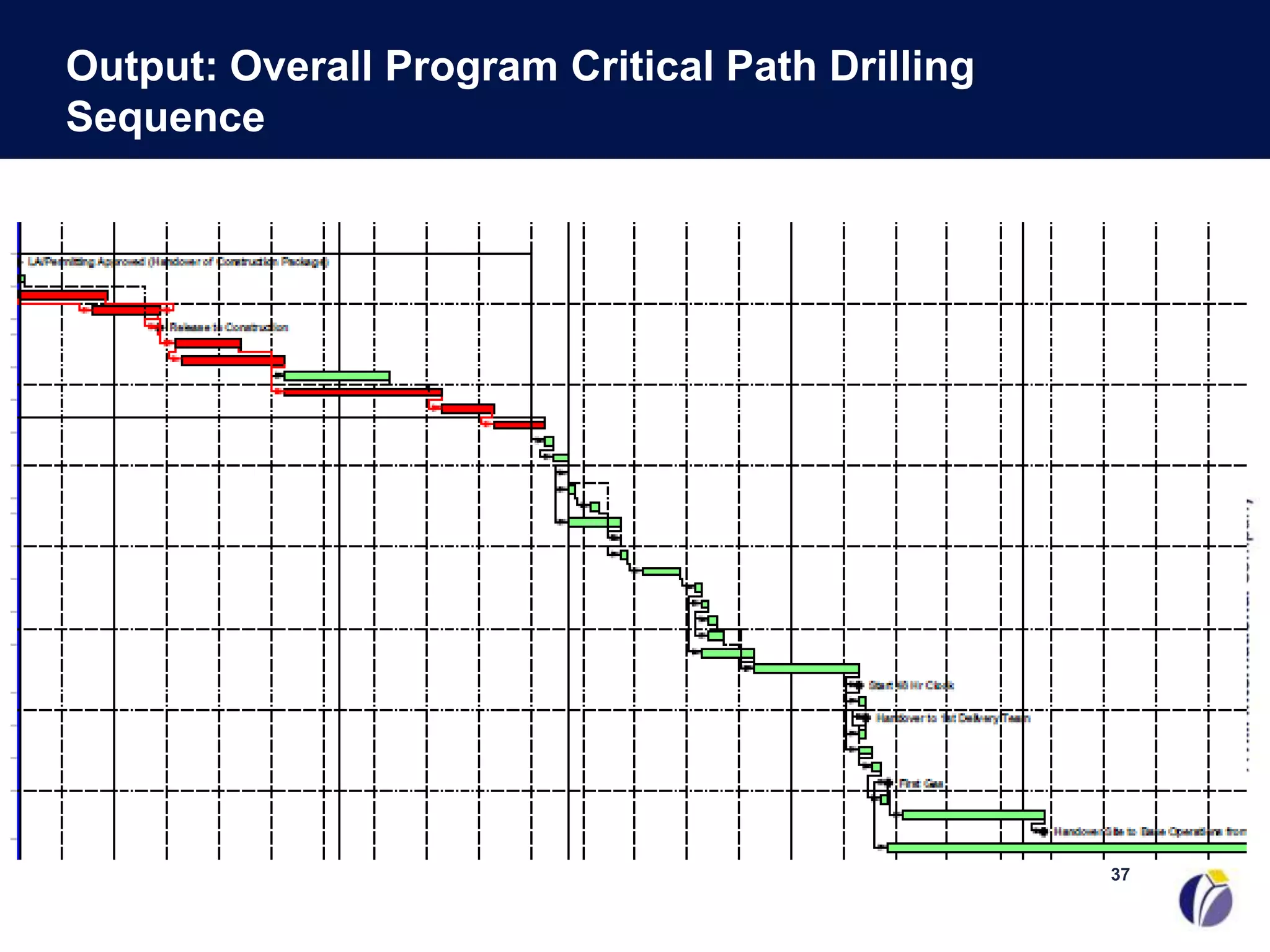

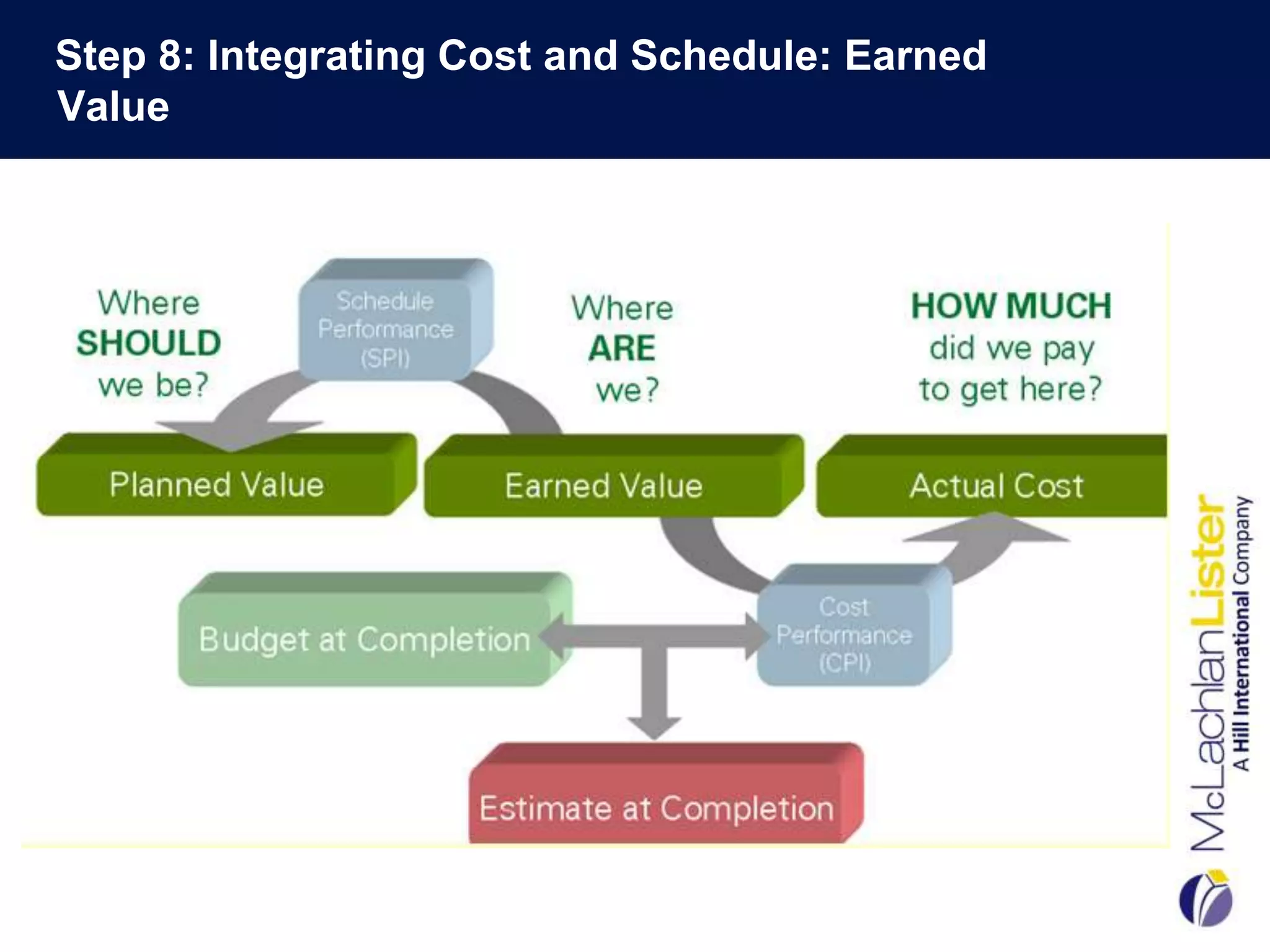

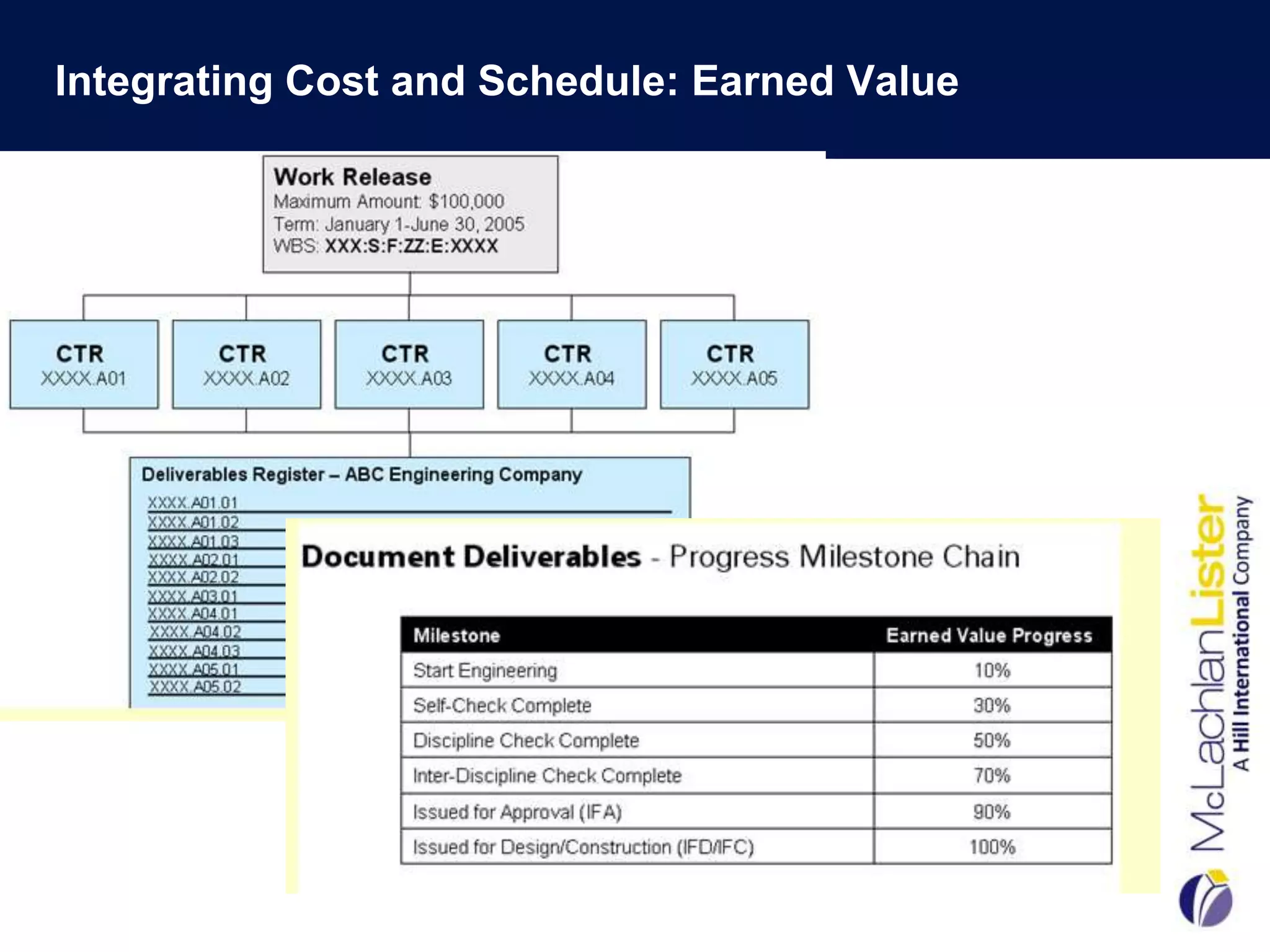

The document outlines effective project control strategies implemented by Dr. Anamaria Popescu for a coalbed methane drilling program involving significant investment and environmental considerations. Key steps included developing a Work Breakdown Structure (WBS), integrated scheduling, risk assessment, and establishing a contingency management system to enhance project efficiency and accountability. The approach emphasizes collaboration, education, and hands-on involvement to ensure stakeholder understanding and commitment to the project's goals.