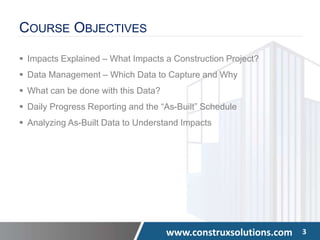

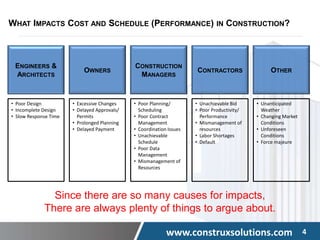

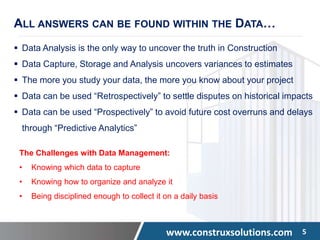

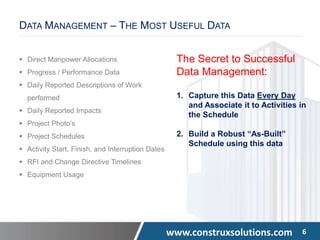

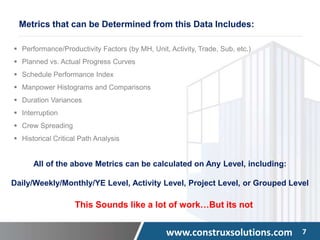

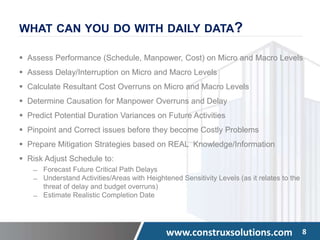

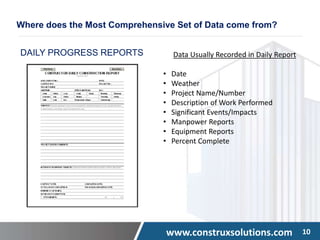

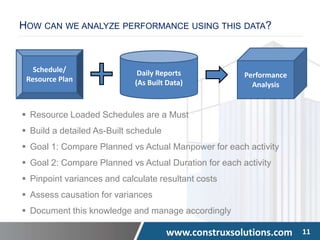

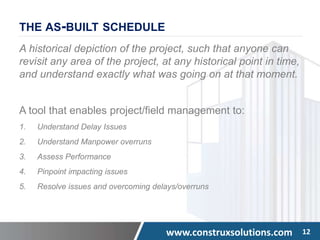

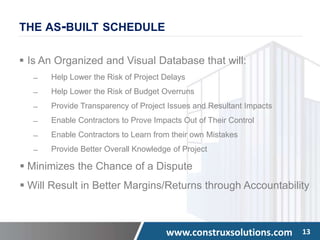

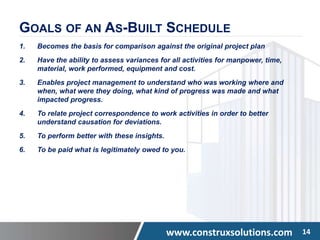

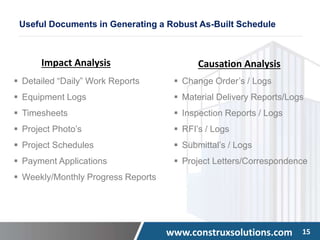

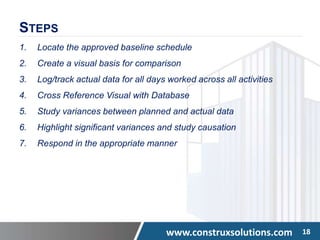

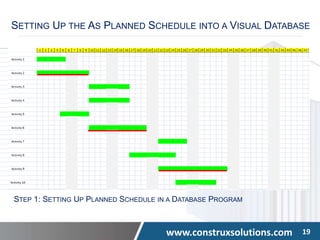

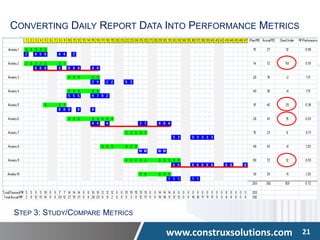

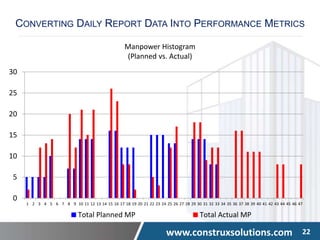

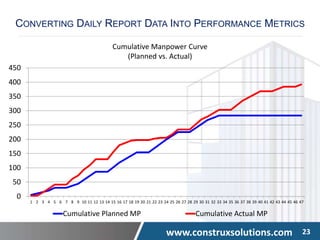

Michael A. Pink’s presentation focuses on data analysis and management in construction, emphasizing its importance for understanding impacts on project performance. Key objectives include identifying crucial data to capture, analyzing it for dispute resolution, and using it for predictive analytics to avoid future issues. The presentation highlights the need for robust as-built schedules and consistent data collection to assess performance and mitigate risks.