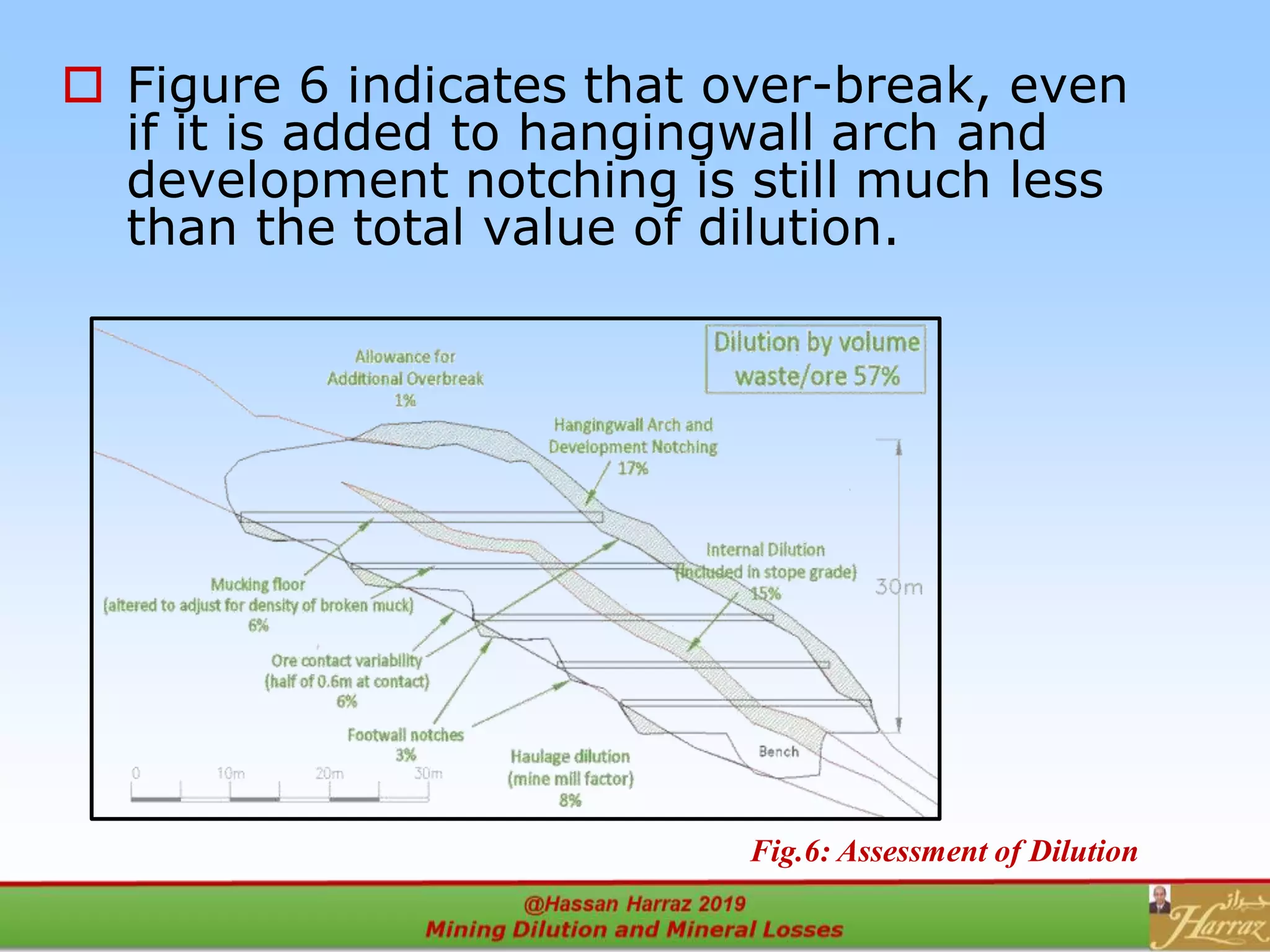

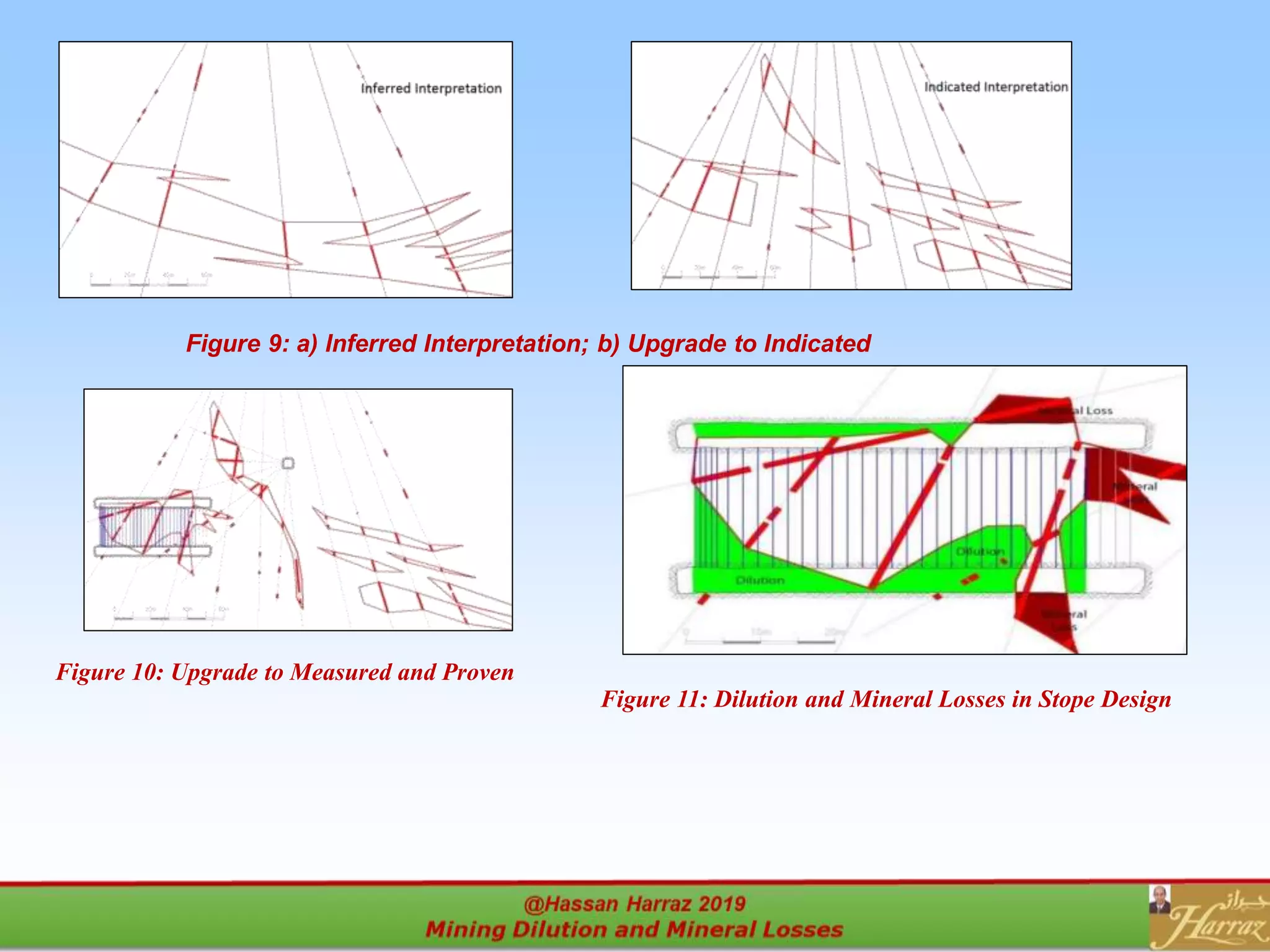

The document discusses the critical issues of mining dilution and mineral losses in underground mining operations, emphasizing their impacts on mine evaluation and economics. Various examples illustrate how operational practices and reporting can lead to misleading representations of dilution, the manipulation of resource models, and the importance of accurate evaluations to maintain investor confidence and uphold industry credibility. Additionally, it outlines factors contributing to mineral losses and stresses the need for better resource upgrade assessments and understanding of ore contact variability in mining designs.