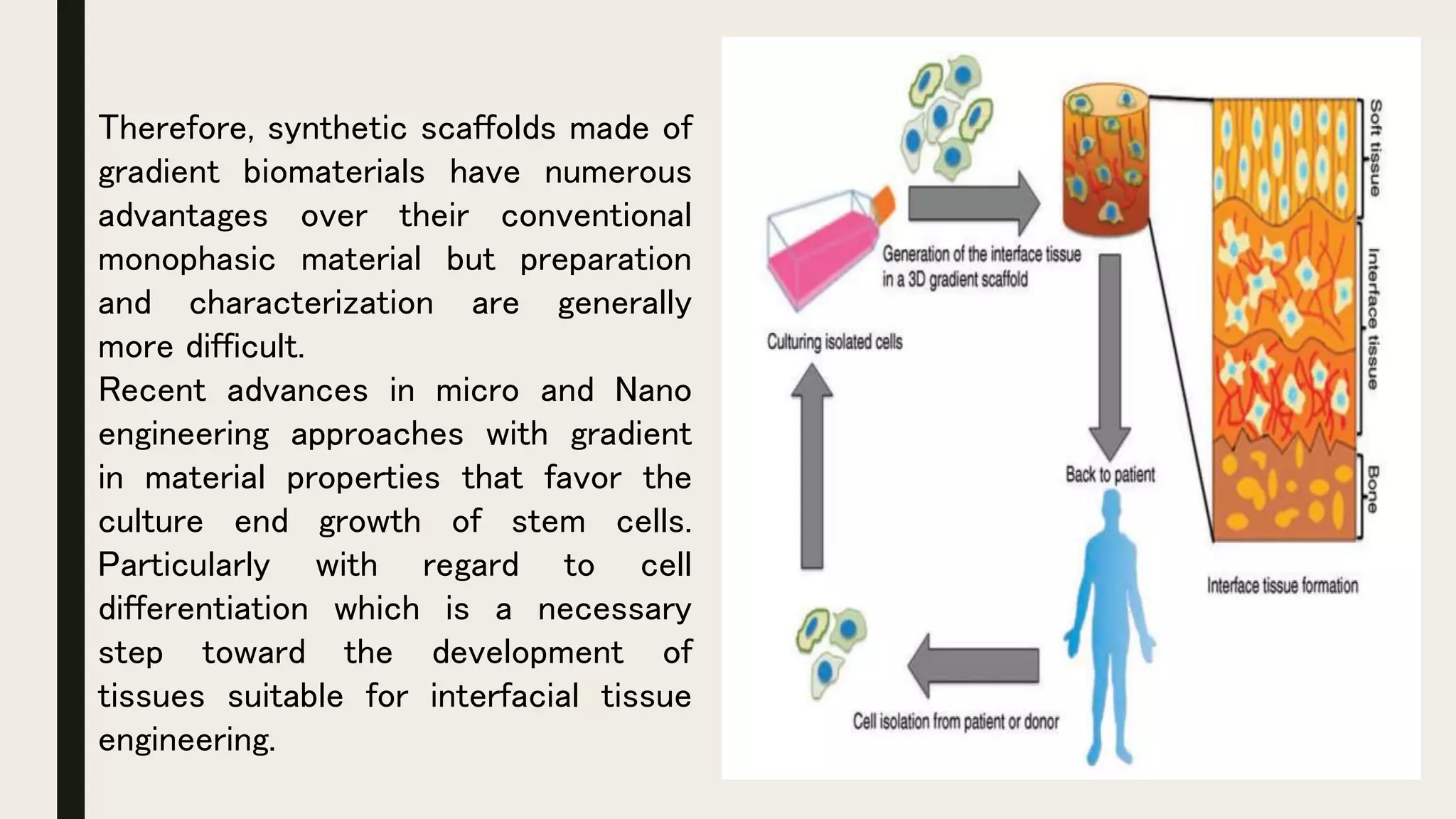

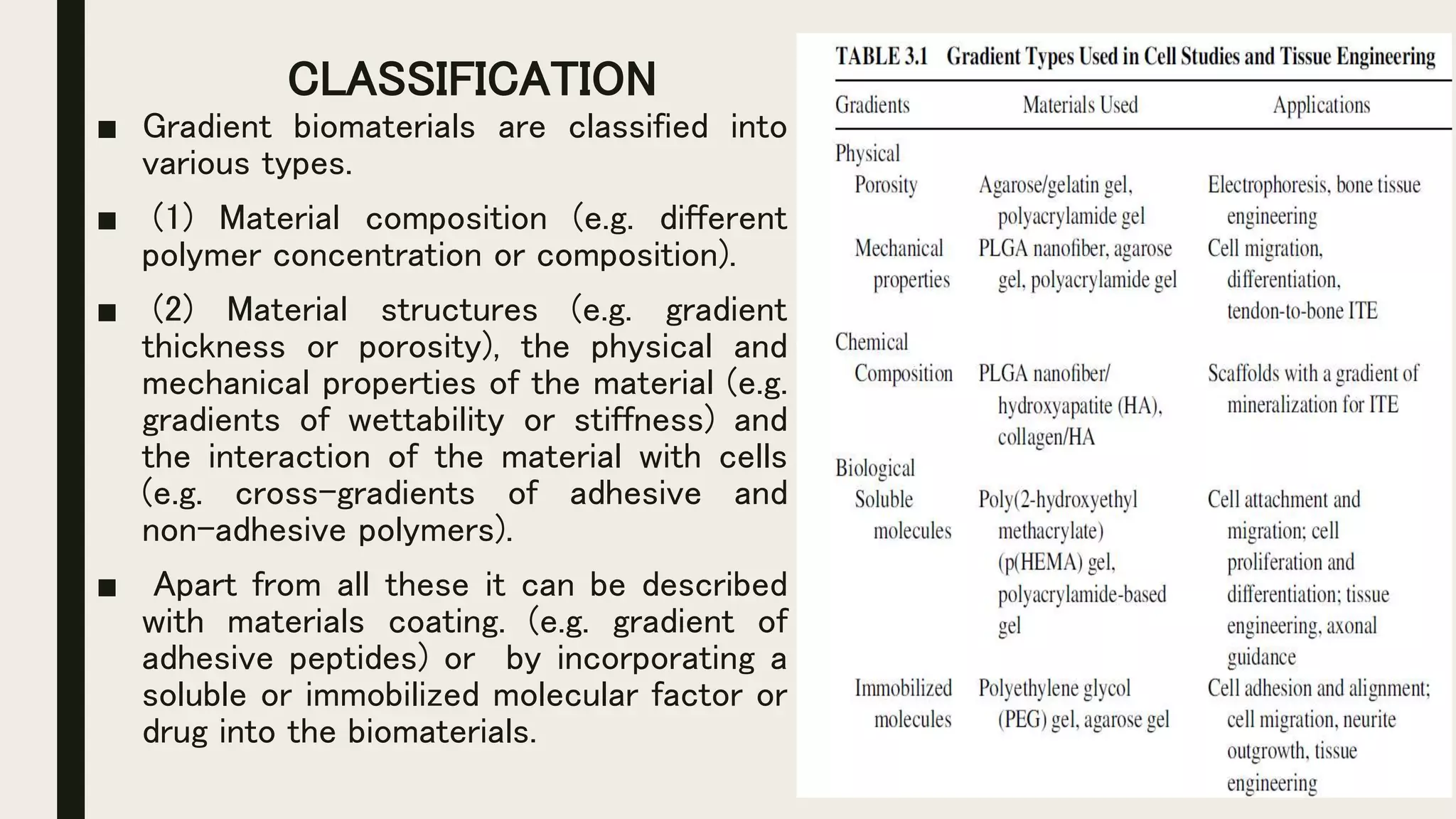

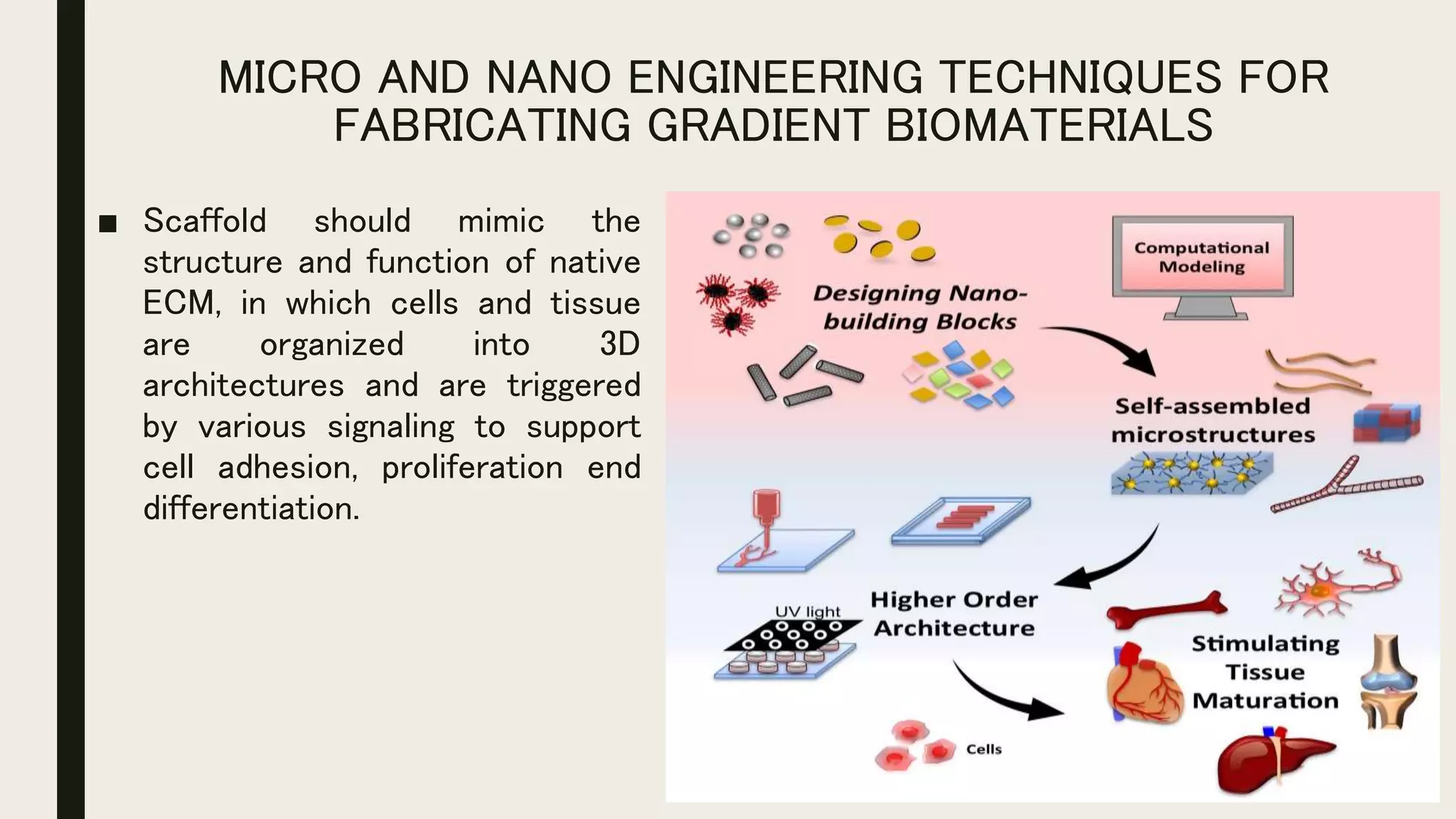

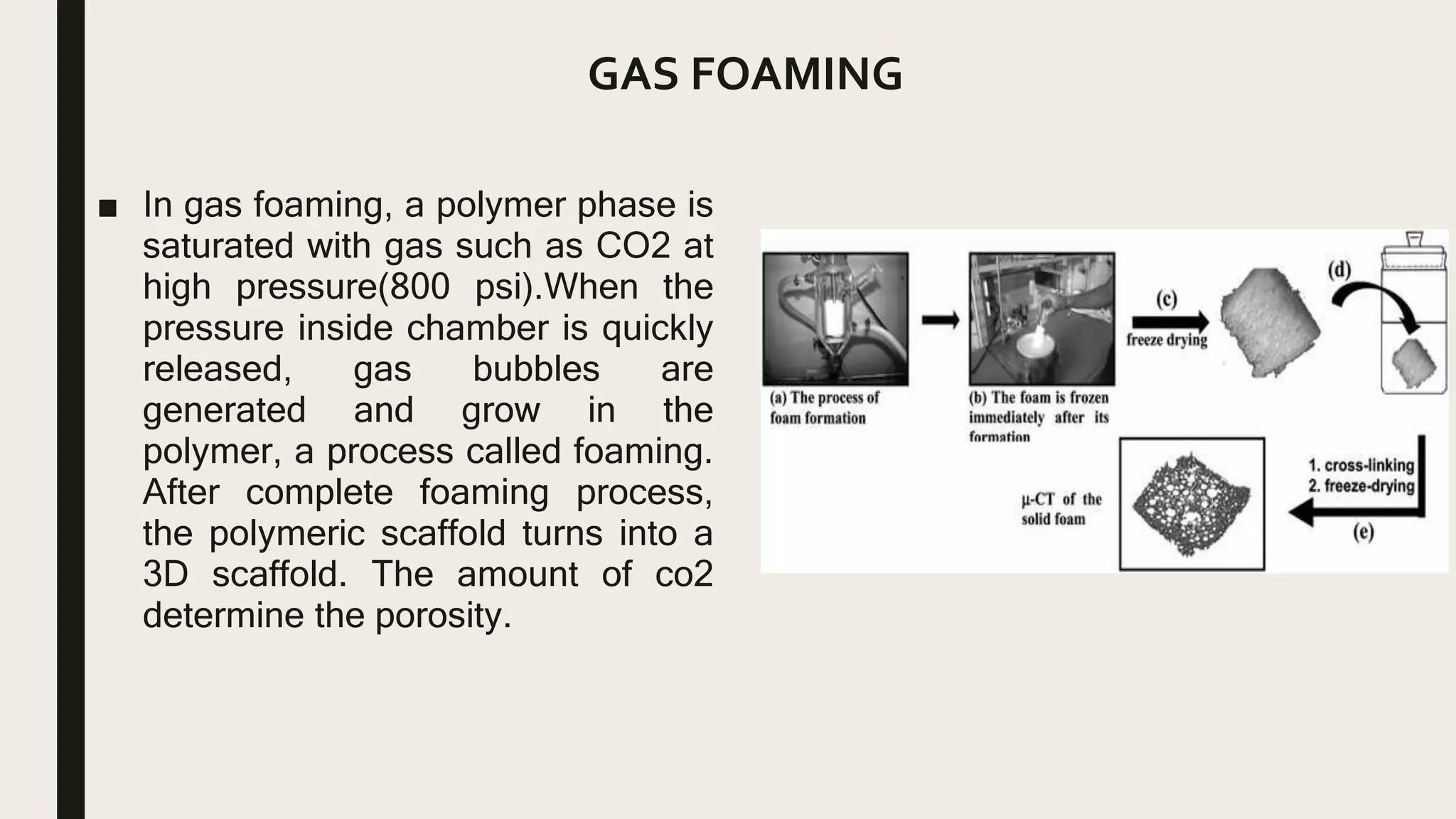

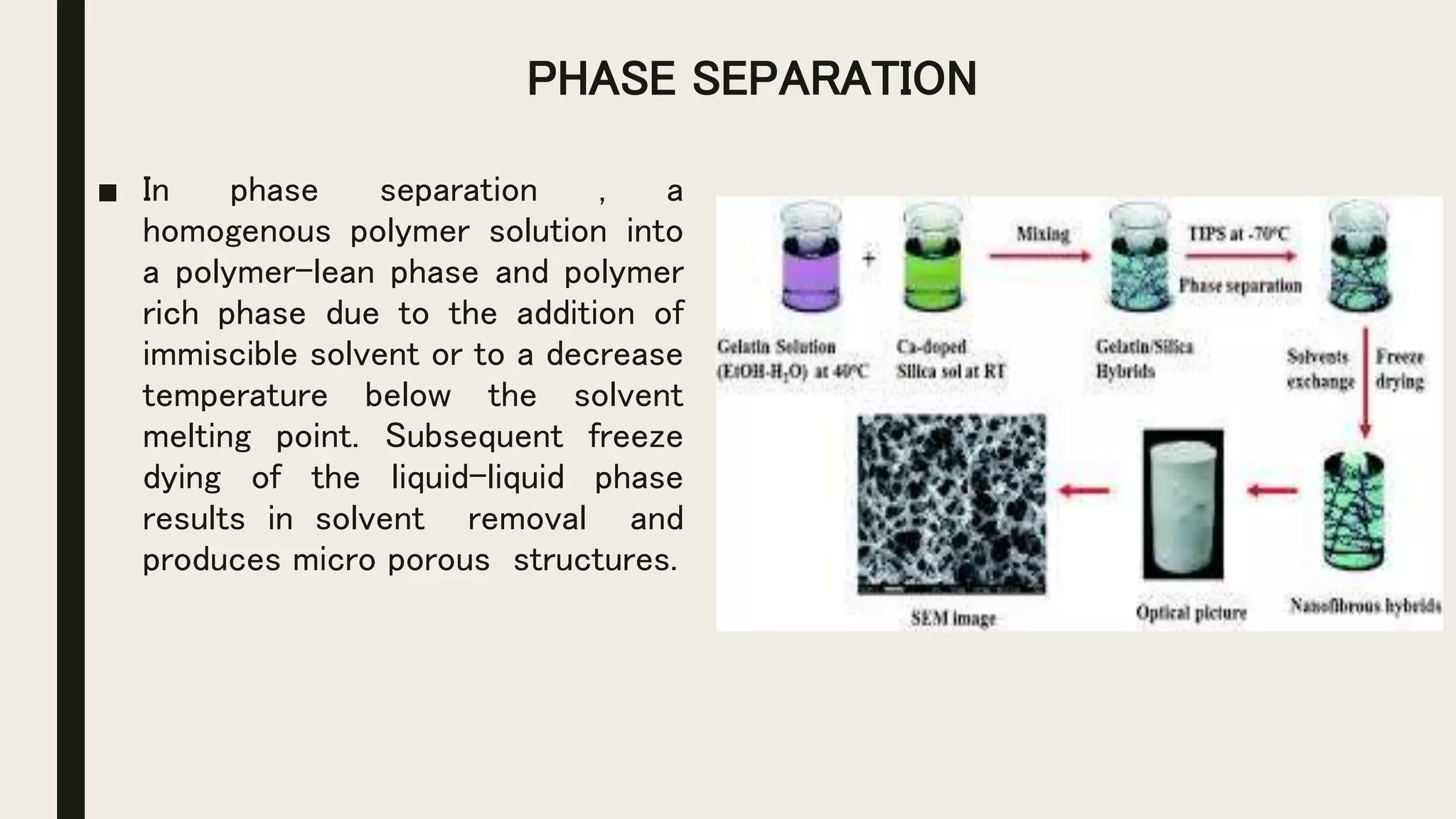

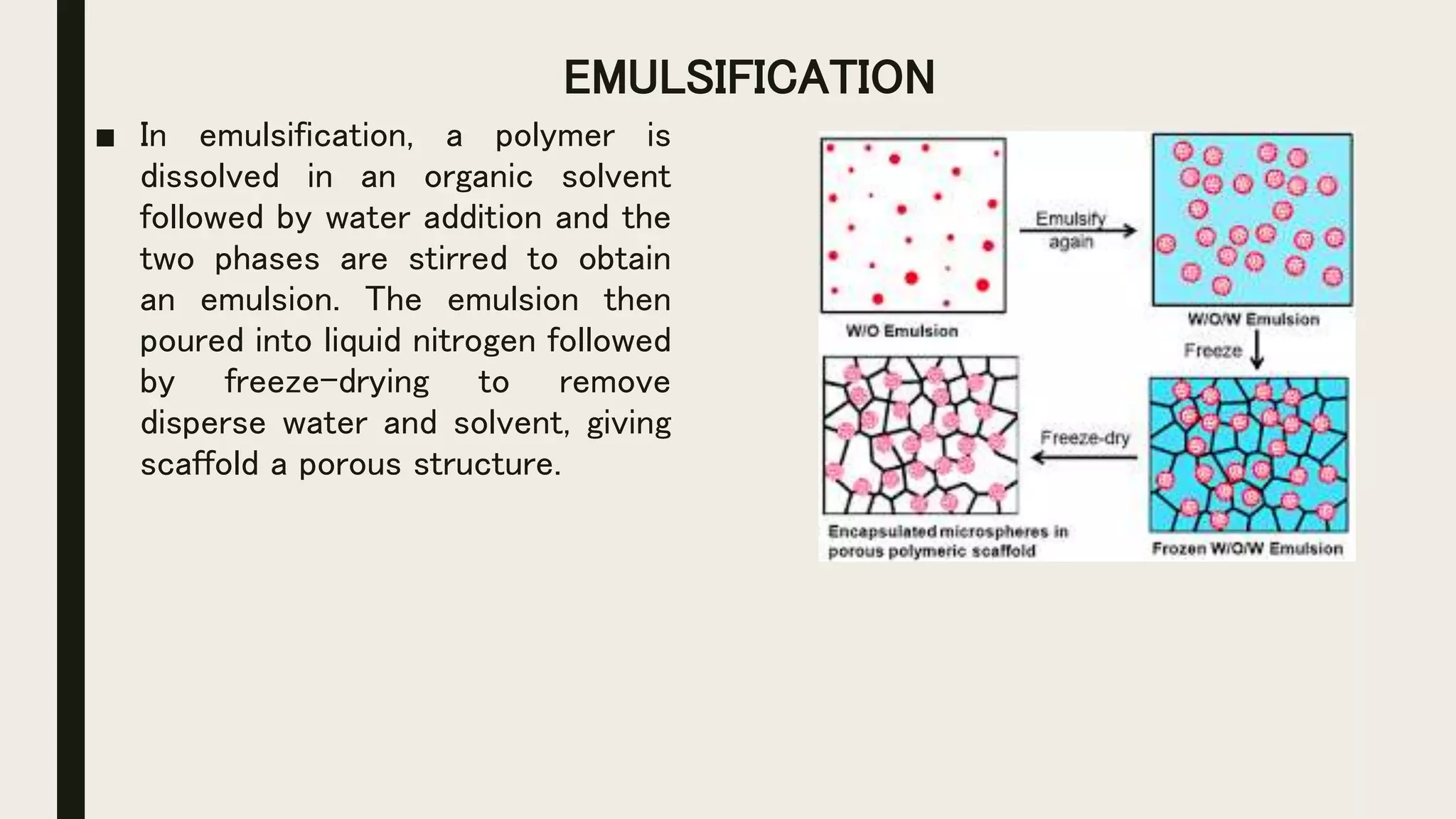

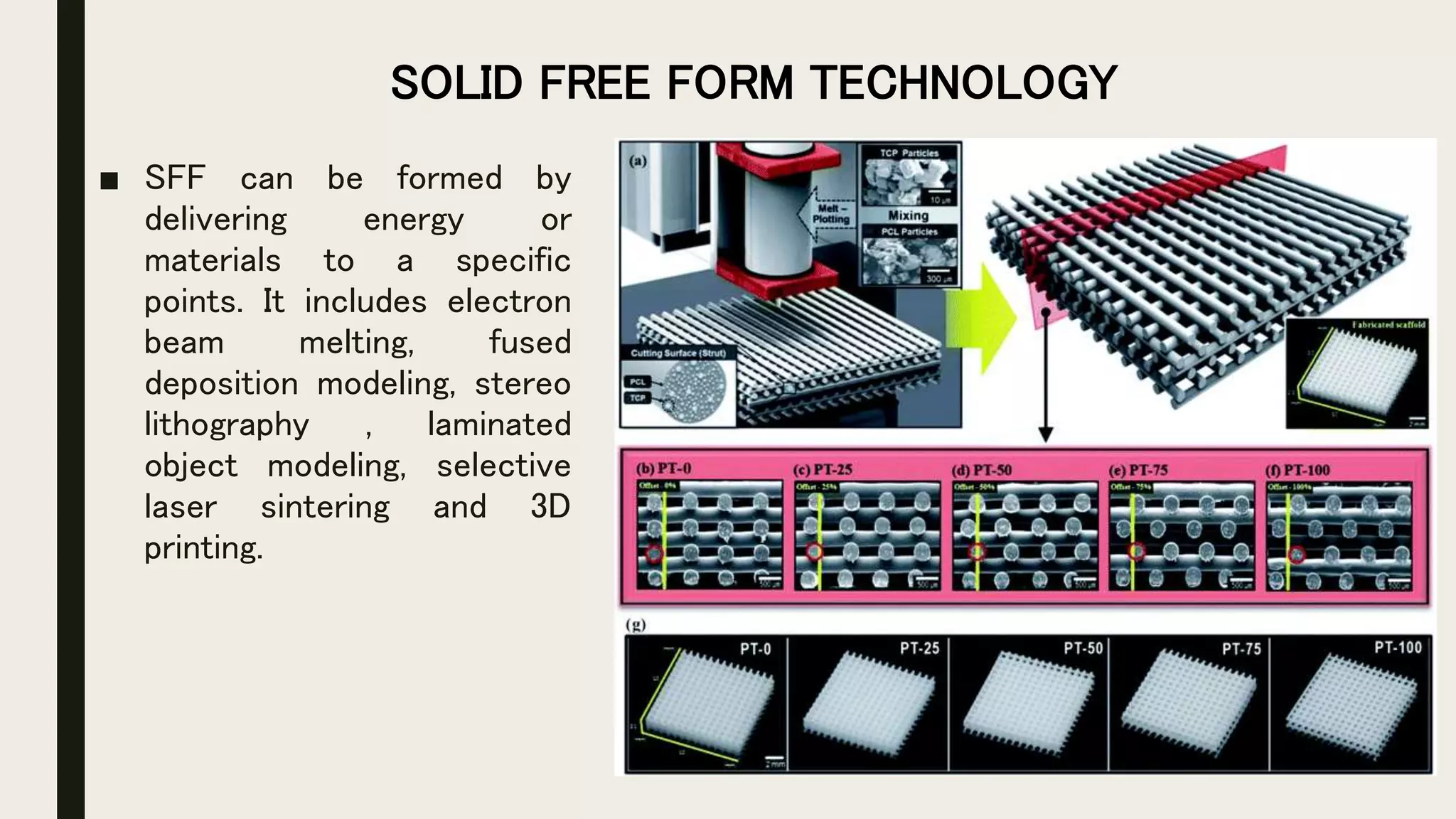

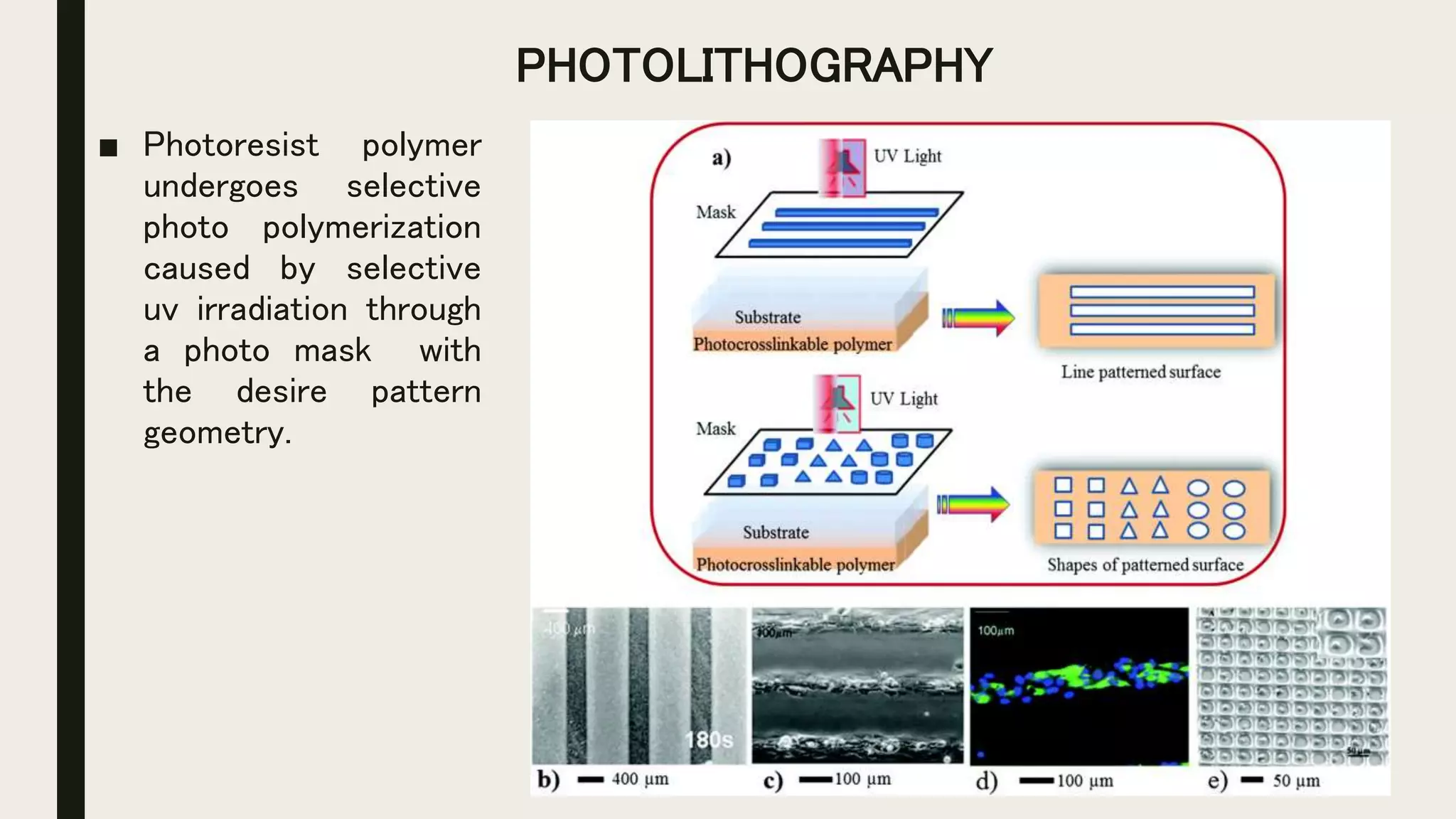

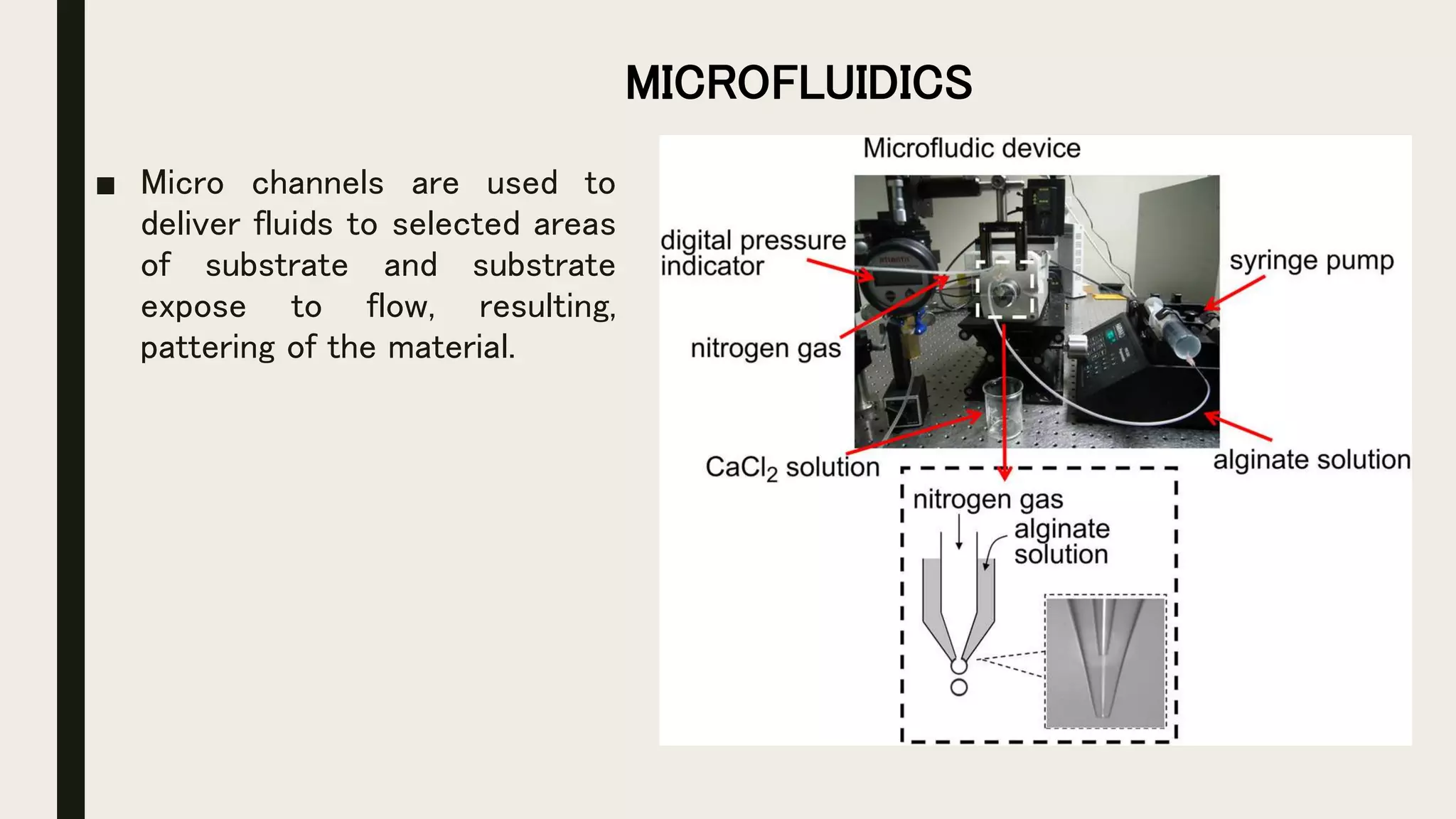

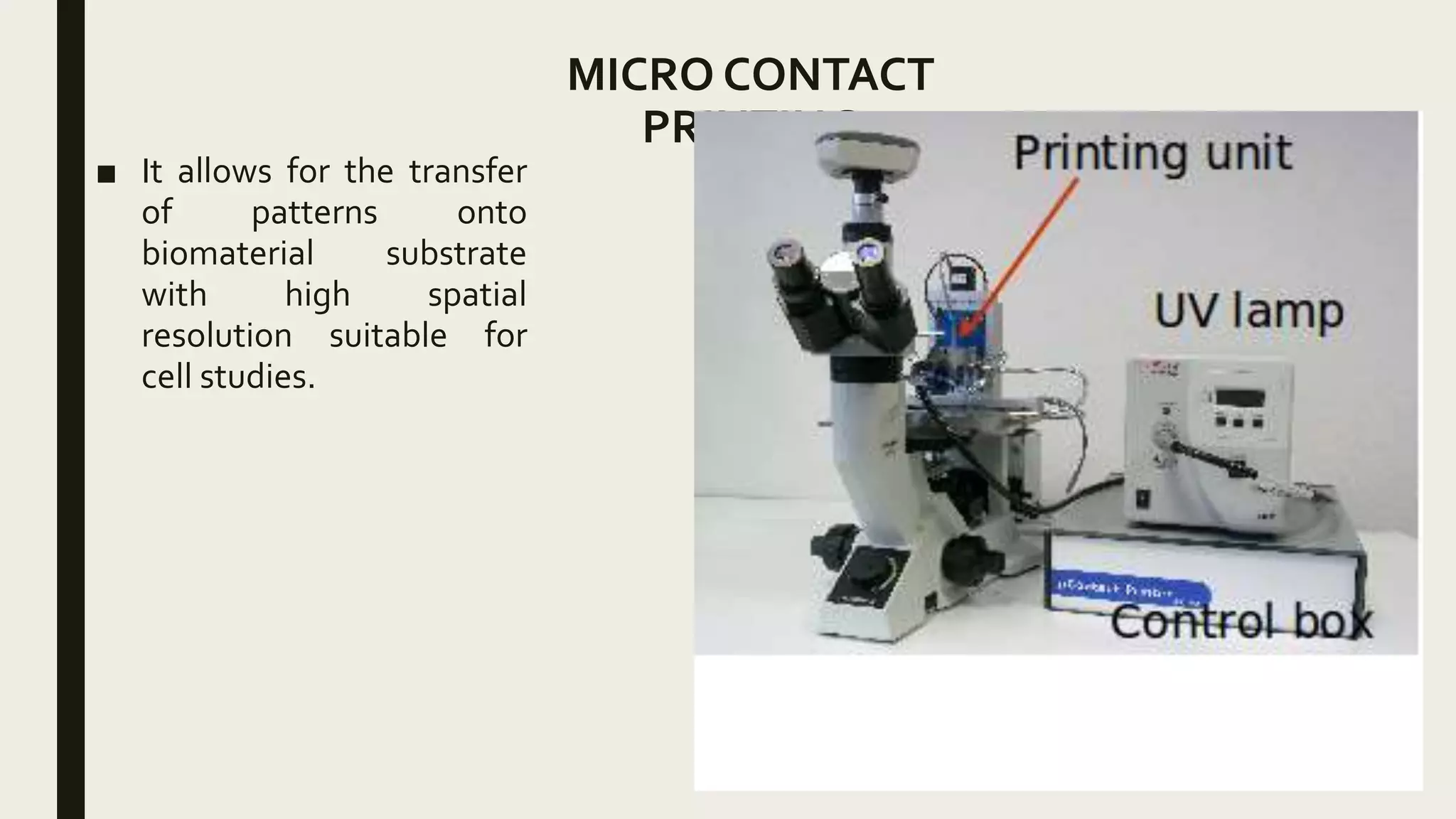

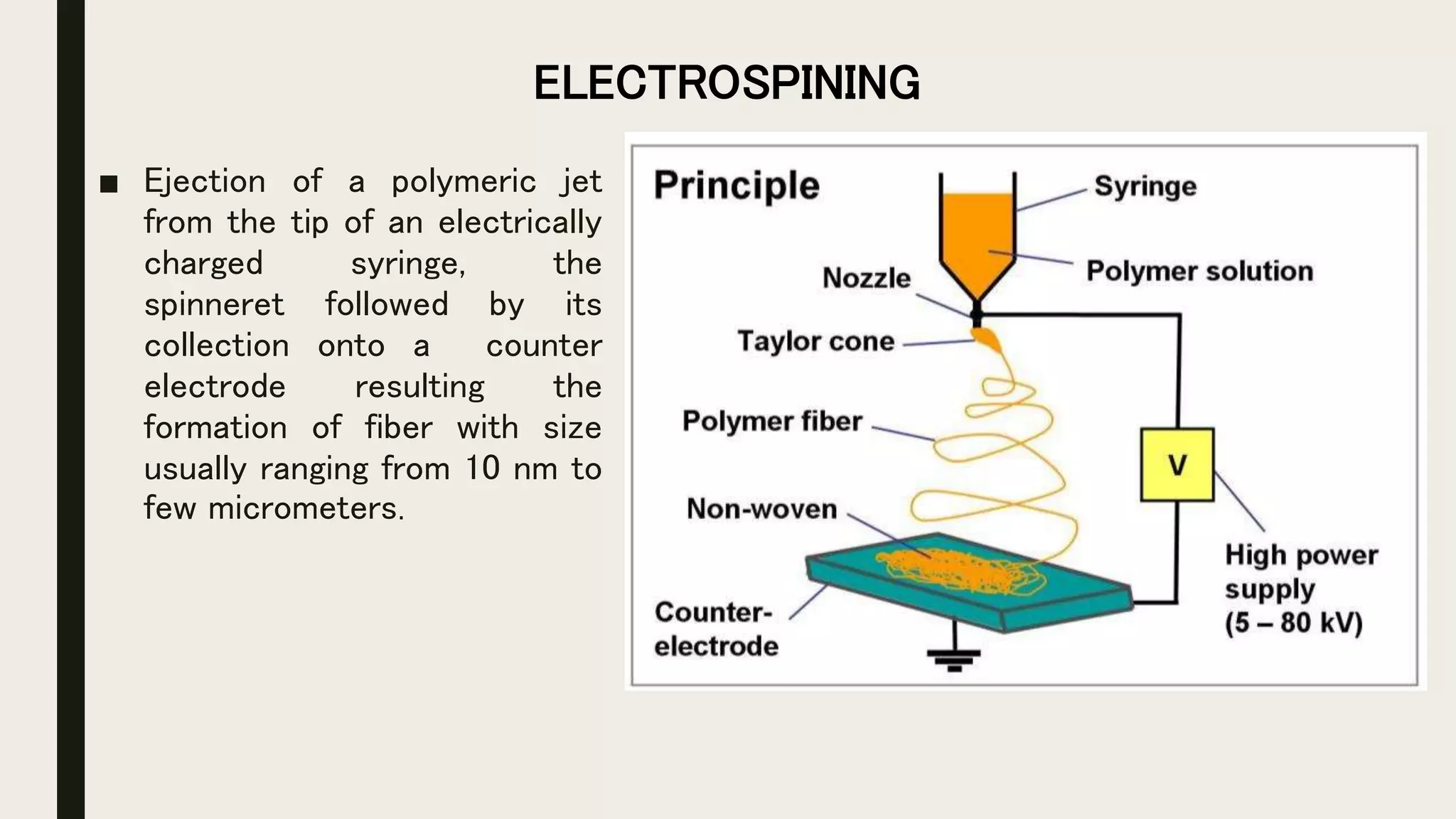

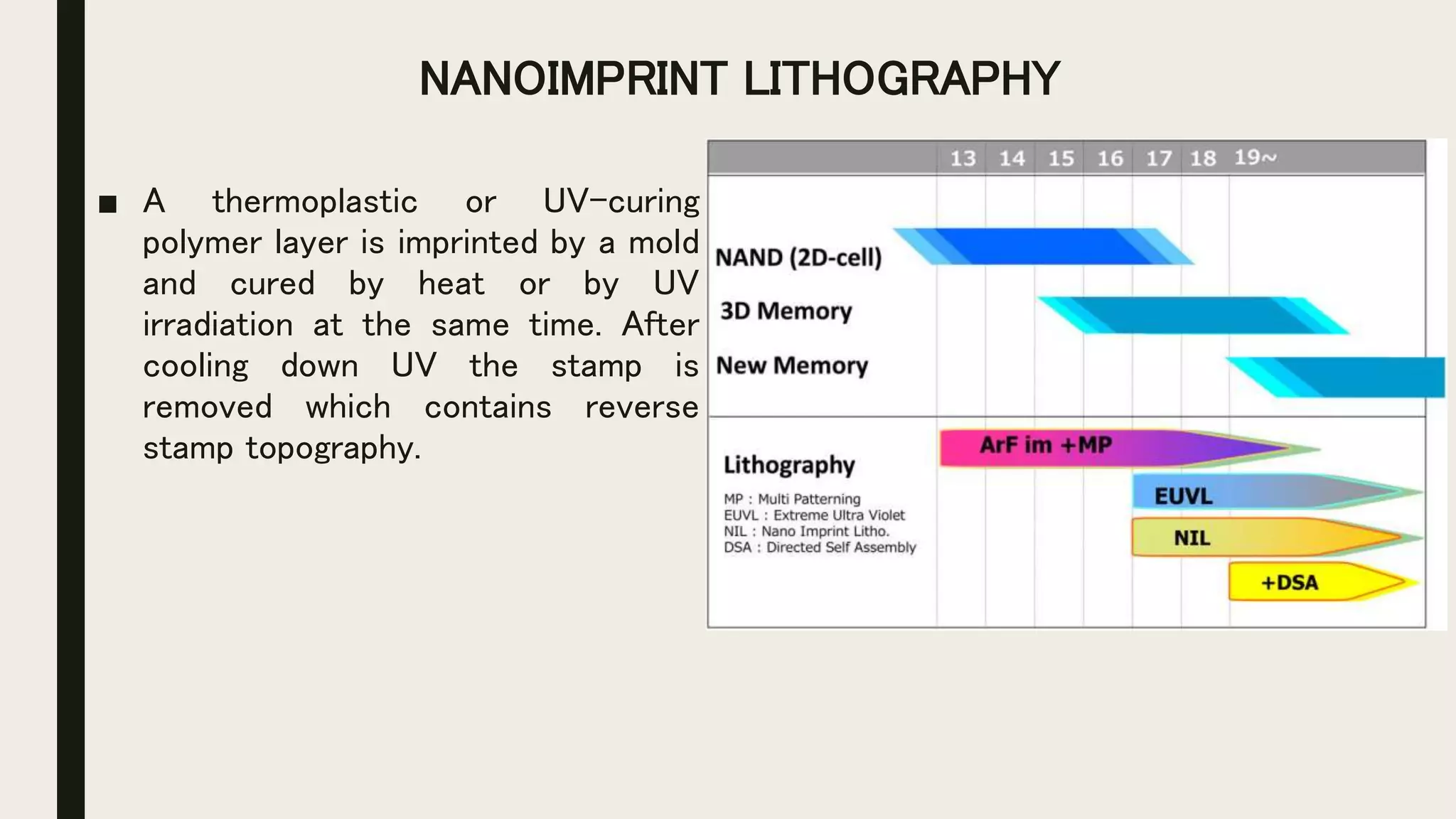

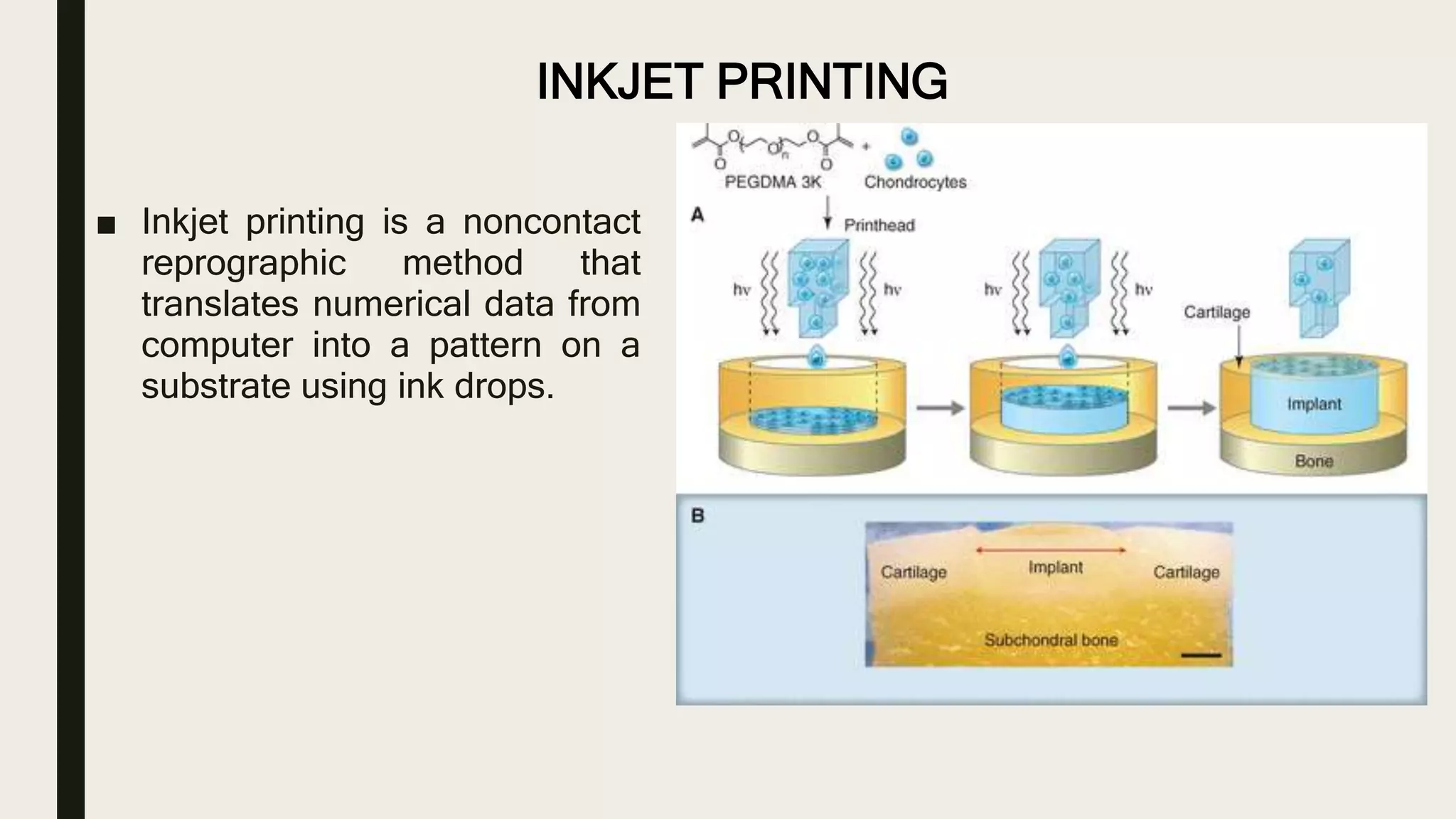

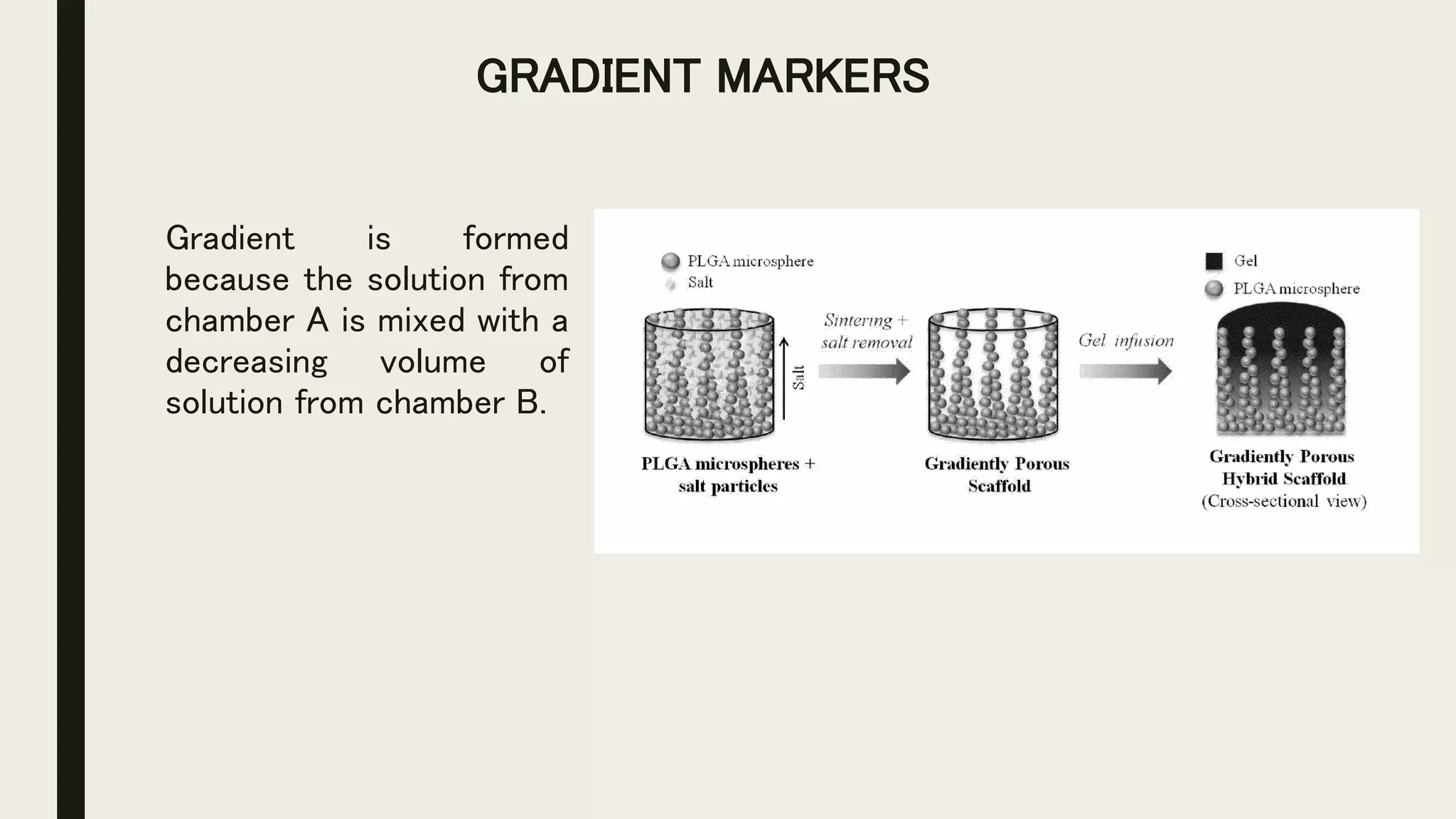

This document discusses approaches for developing gradient biomaterials suitable for interface tissue engineering. It explains that gradient biomaterials can regulate cell behavior during tissue formation at interfaces between soft and hard tissues. The document then describes various types of gradient biomaterials, including those involving material composition, structure, physical properties, and biological factors. It also outlines several micro and nanoengineering techniques that can be used to fabricate gradient biomaterials, such as salt leaching, gas foaming, photolithography, and electrospinning.