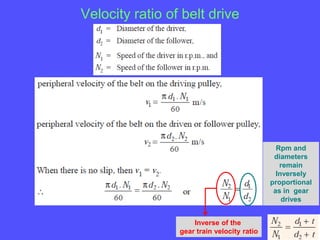

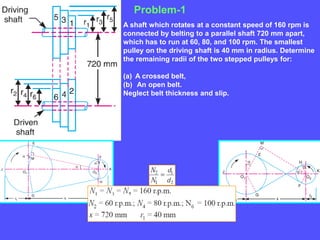

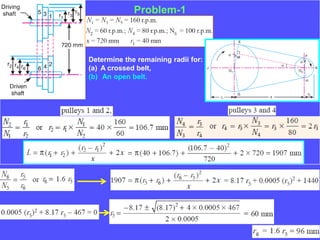

Here are the steps to solve this problem:

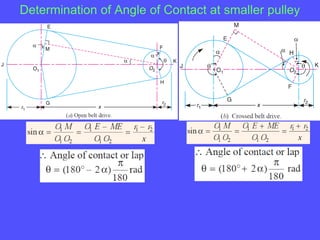

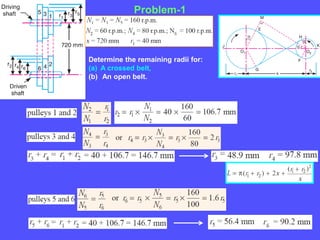

(a) Crossed belt:

Velocity ratio for 60 rpm = 160/60 = 2.667

Radius of smaller pulley = 2.667 * 40 = 106.68 mm

Velocity ratio for 80 rpm = 160/80 = 2

Radius of larger pulley = 2 * 40 = 80 mm

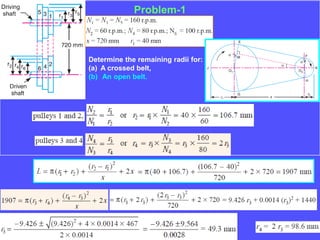

(b) Open belt:

Velocity ratio for 60 rpm = 160/60 = 2.667

Radius of smaller pulley = 2.667 * 40 = 106.68 mm

Velocity ratio for 100 rpm = 160/100 = 1.6

Radius of larger pulley = 1.6 * 40 = 64 mm