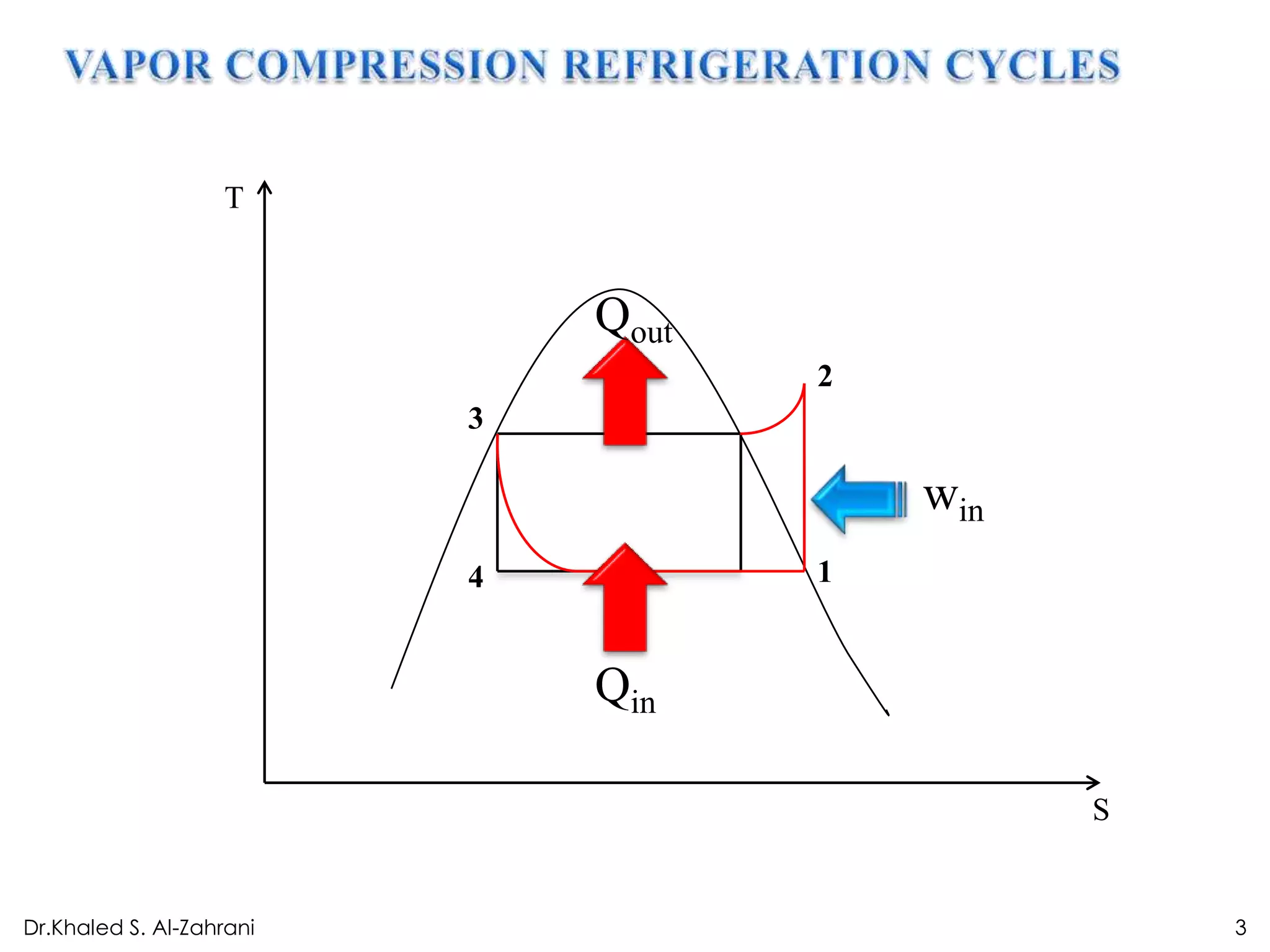

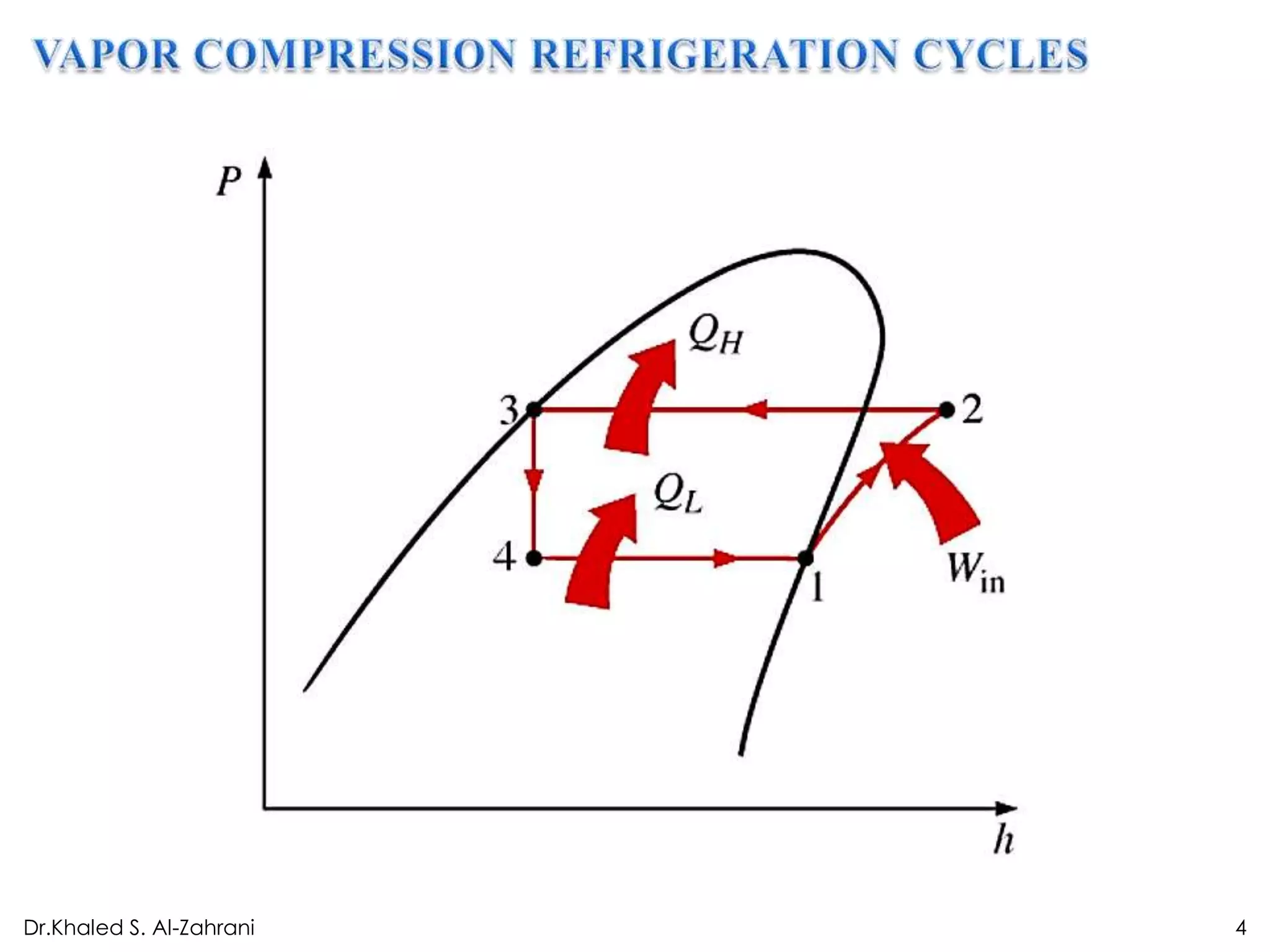

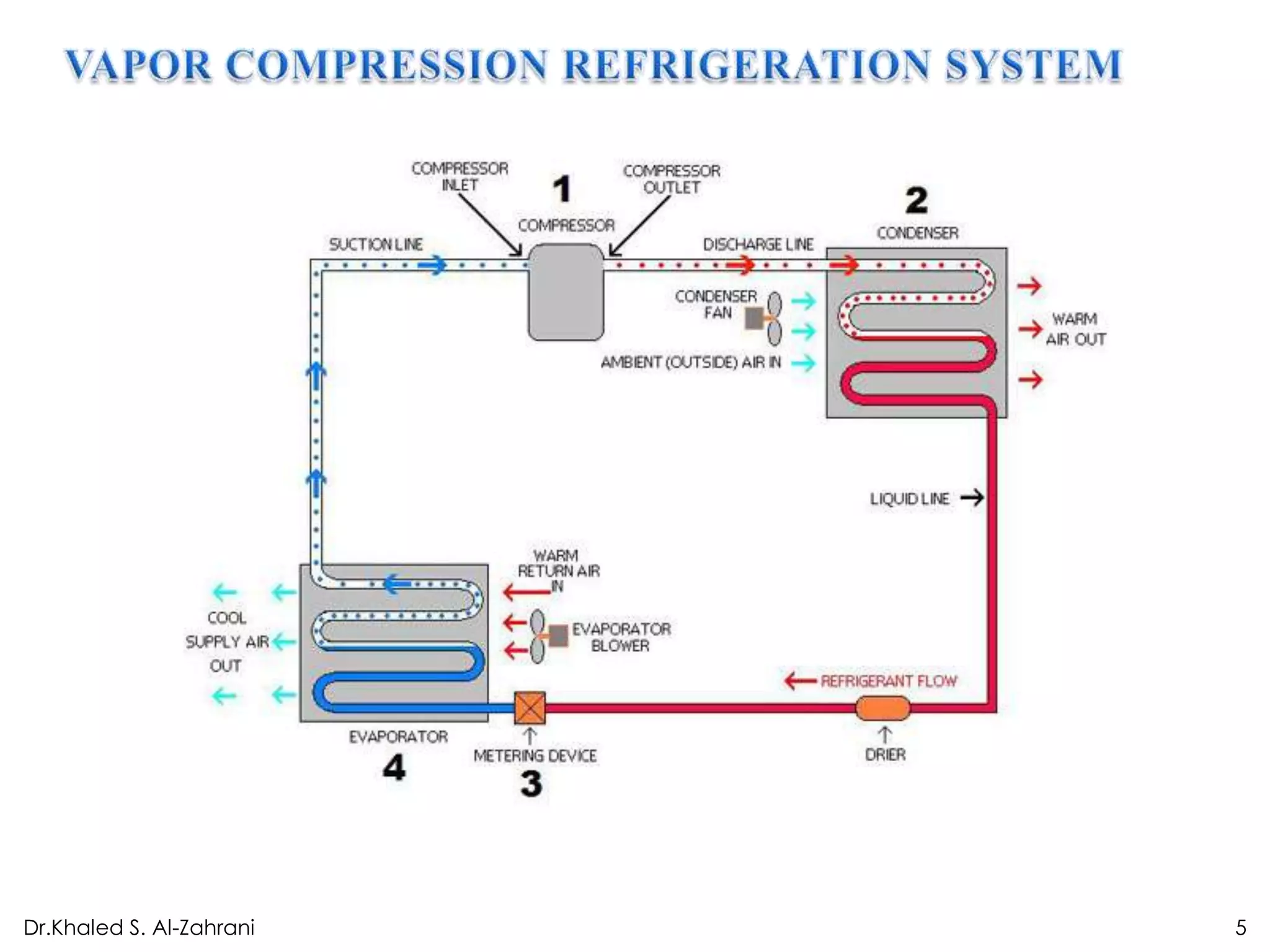

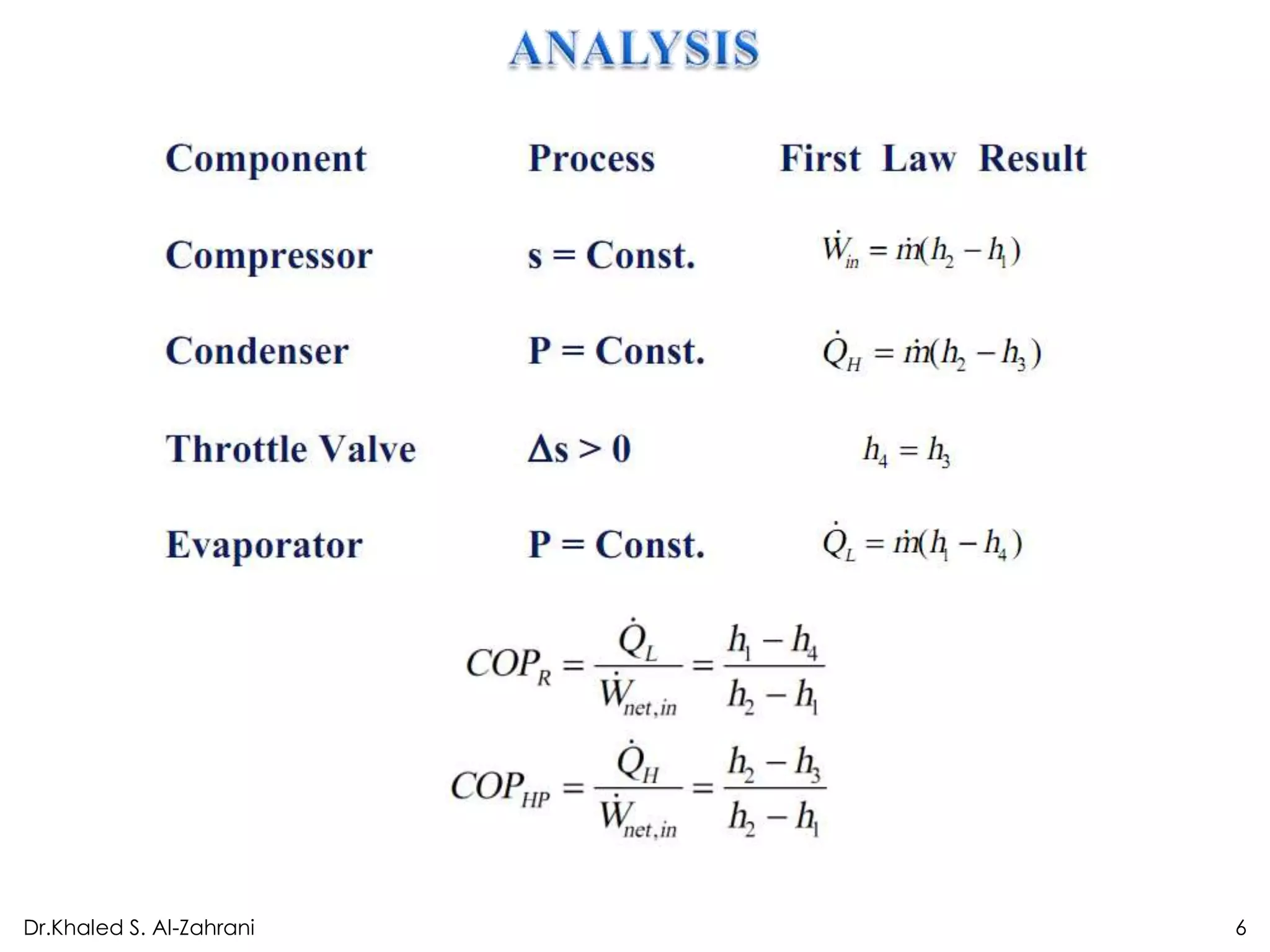

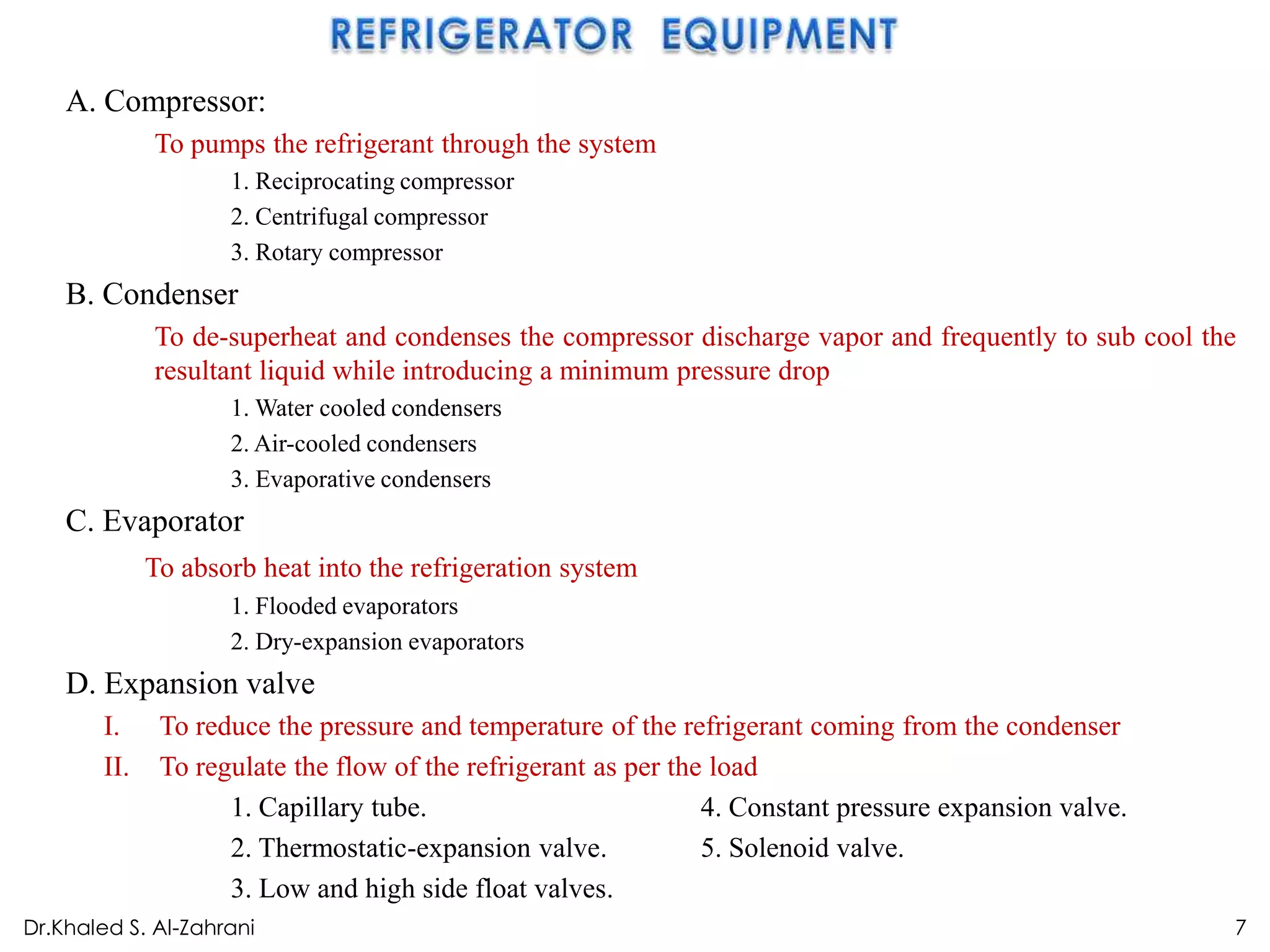

This chapter discusses refrigeration and refrigeration systems. It describes refrigeration as maintaining a system or body at a lower temperature than its surroundings using mechanical or heat energy. The key components of a refrigeration system are identified as the compressor, condenser, expansion valve, and evaporator. Common refrigerants are also discussed, along with their ideal properties. The refrigeration cycle operates by absorbing heat in the evaporator and rejecting heat in the condenser.